Choose Lonnmeter for accurate and intelligent measurement!

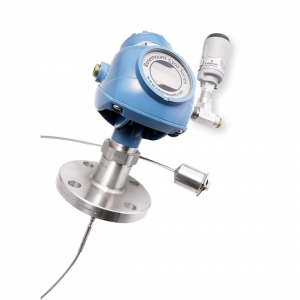

LONN-3X Inserted Flat-diaphragm Pressure Transmitter

Features

n Sanitary type to prevent scaling from blocking pressure inlet

n Use of 316L isolation diaphragm and stainless steel case. Ceramic capacitor sensor can measure high temperature medium.

n Two-wire system standard 4-20mA signal output; customized RS485 signal or HART signal output is available;

n General precision: 0.25 grade, customized 0.1 grade is available;

Multiple process interfaces and electrical interfaces are available for selection;

Applications

Our pressure transmitters are suitable for industries with high hygienic requirements, such as food, hygiene, brewing, etc. It can also be used to measure viscous media, effectively solving the problem of easy blockage of pressure ports. By providing accurate pressure measurement, our products ensure process stability and meet hygiene requirements. In the food industry, our pressure sensors enable precise pressure measurement during production, ensuring optimum product quality and safety.

In hygienic applications, it helps maintain clean and hygienic conditions, which is especially important in healthcare facilities and laboratories. For the brewing industry, our pressure sensors ensure precise control of pressure during fermentation and storage, resulting in high-quality and consistent beer. The ability of pressure transmitters to measure viscous media is critical in industries such as oil and gas to ensure the proper operation of pipelines and equipment. It is also valuable in chemical processing, where accurate pressure monitoring is critical to safety and product quality. The product's customization options for process and electrical interface further enhance its versatility and applicability across industries. In conclusion, our pressure transmitters are the reliable and hygienic solution for precise pressure measurement. It is suitable for industries with high hygienic requirements and for applications involving viscous media and pressure ports that are prone to clogging.

If you have any questions or requests about our pressure transmitters, please feel free to contact us. Our team will provide professional assistance and customized solutions.

Parameters

| Range | `-100~0~5、100、500、800、1000kPa 0~2、10……10MPa |

| pressure form | Gauge pressure, negative pressure, absolute pressure |

| output signal | 4~20mA, 4~20mA+HART protocol, 4~20mA+RS485 protocol |

| Input voltage | 12~36V DC |

| Accuracy | 0.1 0.2(0.25) 0.5 |

| non-linear Repeatability hysteresis |

0.1 0.2(0.25) 0.5 |

| Zero point and sensitivity drift | 0.01 0.02(0.025) 0.005 |

| Compensation temperature | -10℃~70℃ |

| Operating temperature | -20~+85℃ |

| long-term stability | ≤0.1±%FS/year |

| Response time | <1ms |

| overload capacity | 200% |

| Load Resistance | R=(U-12.5)/0.02-RD |

| Measuring medium | Corrosive media compatible with 316L |

| Diaphragm material | 316L stainless steel |

| Shell material | 1Cr18Ni9Ti |

| Degree of protection | IP67 |