The performance of any fuel, particularly heavy fuel oil viscosity control, is never a matter of chance. It is an engineered property that determines how efficiently fuel flows, atomizes, burns, and ultimately powers engines, turbines, or industrial processes. Ignoring fuel viscosity can lead to incomplete combustion, accelerated wear, excessive emissions, and costly downtime. For industries that depend on reliable fuel handling—from marine shipping to power generation—controlling fuel oil viscosity is not simply a technical preference, it is a survival strategy.

Fuel Quality Standards Evolution

International regulations have progressively tightened specifications on heavy fuel oil characteristics over the decades. From sulfur content to water contamination limits, viscosity has remained one of the most decisive factors in establishing compliance. Earlier fuels tolerated broader viscosity ranges, but the rise of high-performance engines and stricter environmental laws means viscosity must now be measured and controlled with exceptional precision. Fuel standards such as ISO 8217 highlight viscosity as a benchmark property, forcing operators to adopt fuel oil viscosity control systems that guarantee consistency under varying supply conditions.

Combustion Technology Advancements and Viscosity Needs

Modern combustion systems—whether diesel engines, gas turbines, or industrial burners—rely on fine fuel atomization to ensure uniform air–fuel mixing. Achieving the desired spray pattern is impossible if the fuel viscosity is outside its optimal window. Low viscosity may lead to leakage and poor pressure buildup, while excessively high viscosity causes poor atomization, incomplete combustion, and deposits inside injectors. As engines are designed with tighter tolerances and higher pressures, the demand for precise viscosity management has become non-negotiable.

Traditional Fuel Viscosity Measurement Techniques

Historically, laboratories relied on capillary viscometers, Redwood viscometers, and Saybolt units to measure heavy fuel oil viscosity. While accurate in controlled environments, these techniques required sampling, manual handling, and delayed results. In fast-moving industrial operations, relying solely on offline testing is risky, because viscosity can change dramatically between storage, heating, and actual injection.

Today, the industry seeks continuous online monitoring, but understanding traditional baselines helps underscore why new technologies are so transformative.

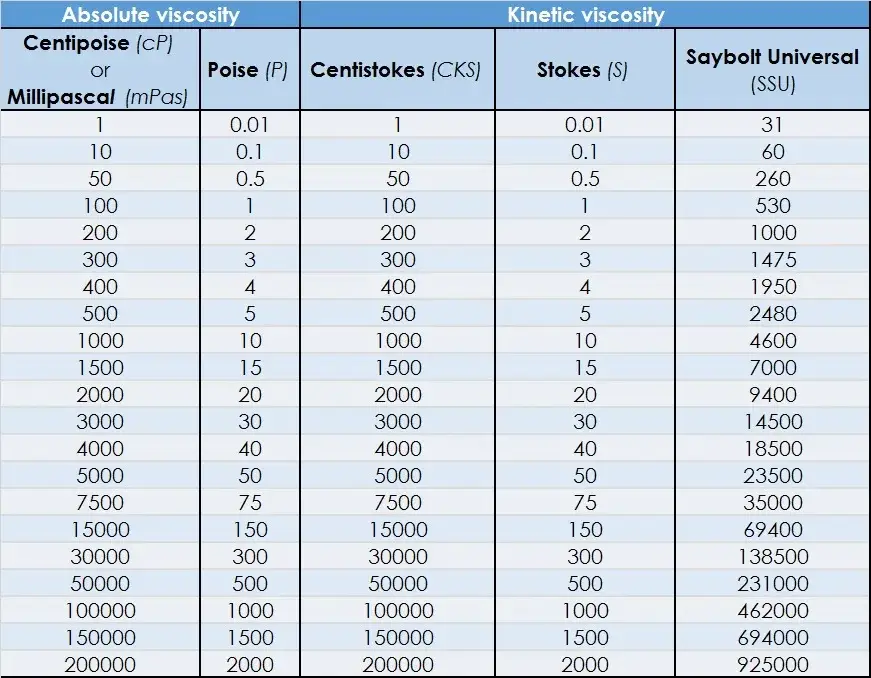

Viscosity Units Explained

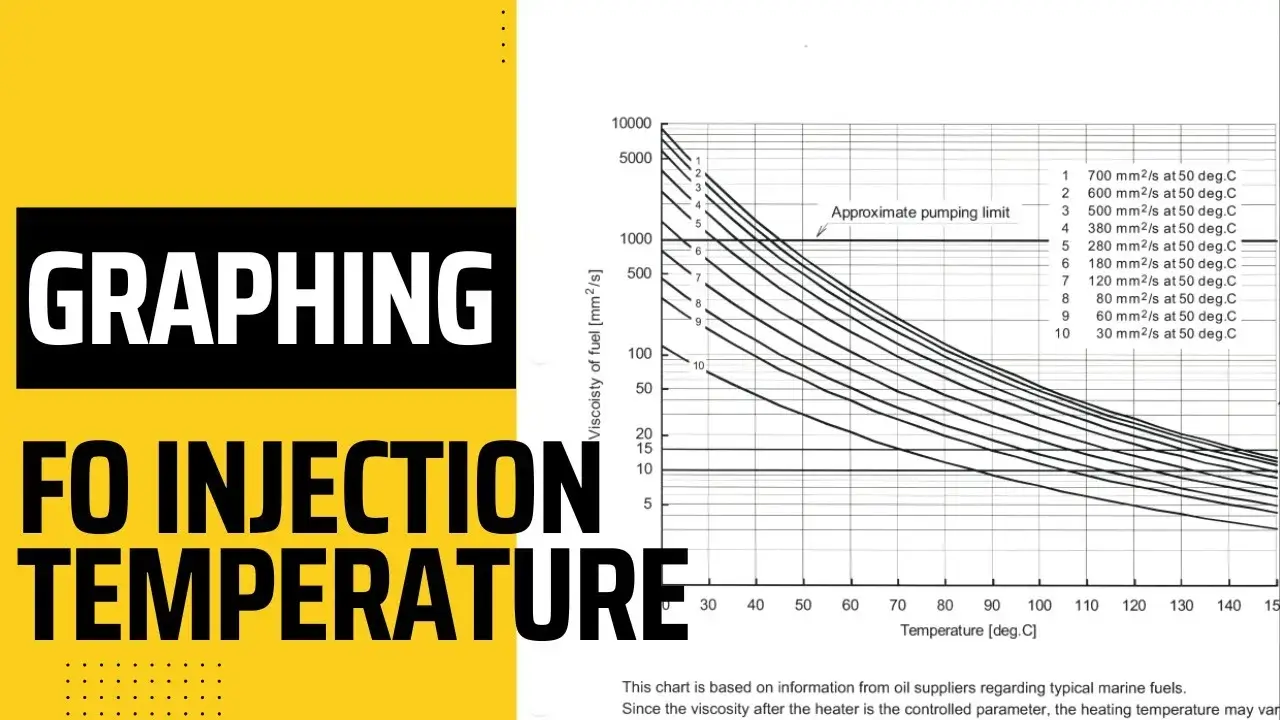

Viscosity is typically expressed in centistokes (cSt), centipoise (cP), or Saybolt Universal Seconds (SUS). Engineers must translate between these depending on equipment manuals and regional standards. For instance, viscosity of heavy fuel oil is often specified in cSt at 50 °C, while marine engines require specific heating curves to adjust viscosity into the injection range of 10–15 cSt. This practical understanding of viscosity units is essential for calibrating heaters, pumps, and viscosity controllers.

How Temperature Affects Fuel Viscosity

Temperature exerts a powerful influence on fuel viscosity. A small increase in heat can significantly reduce the resistance to flow, allowing heavy fuels to atomize effectively.

Operators of marine engines know that heavy fuel oil characteristics demand preheating to at least 120–150 °C before injection. Failure to manage temperature–viscosity relationships can lead to engine knock, incomplete combustion, or pump damage. This is why advanced fuel oil viscosity control systems integrate both heating regulation and viscosity feedback for seamless operation.

Fuel Properties Influencing Viscosity

Several intrinsic properties affect how a fuel resists flow. Aromatic content, asphaltene concentration, and blending ratios with distillates are major contributors. The higher the density and molecular complexity, the greater the fuel viscosity. Impurities such as water, sediment, or sulfur compounds can further distort expected viscosity behavior, making online monitoring indispensable. Understanding these fuel properties helps operators anticipate handling difficulties and design blending strategies that ensure stable heavy fuel oil viscosity.

Challenges in Continuous Fuel Viscosity Measurement

Inconsistent Fuel Quality Challenges

Global sourcing of bunker fuels means operators often face inconsistent supply. Viscosity variations between batches can be dramatic, requiring real-time adjustments to heating and blending strategies. Without reliable monitoring, mismatches in fuel viscosity can cause catastrophic equipment failures.

Process Control Difficulties with Varying Viscosity

A refinery or power plant that processes fuels of fluctuating viscosities faces unstable combustion and reduced throughput. Manual adjustments lag behind reality, making continuous inline measurement the only sustainable solution.

Impact of Incorrect Viscosity on Equipment

Too-high heavy fuel oil viscosity puts stress on pumps and injectors, while too-low viscosity causes leaks and inadequate sealing. Both conditions accelerate mechanical wear, shorten maintenance cycles, and increase operational costs.

Regulatory Compliance for Fuel Specifications

With IMO 2020 sulfur limits and ISO viscosity standards, companies must demonstrate that their fuel oil viscosity control systems meet compliance. Failing to do so risks fines, engine damage, and reputational loss.

Lonnmeter Solutions for Real-Time Viscosity Monitoring

Enhancing Fuel Atomization with Precise Control

Lonnmeter viscosity measurement instruments provide immediate feedback to heating and injection systems, ensuring atomization always occurs within the ideal viscosity window. This translates into cleaner combustion, lower emissions, and better energy conversion efficiency.

Optimizing Pumping Efficiency with Online Data

Viscosity affects not just combustion but also pumping workloads. By maintaining optimal fuel viscosity, Lonnmeter systems reduce stress on pumps and minimize energy losses, helping operators cut operational costs significantly.

Ensuring Consistent Fuel Blending with Lonnmeter

Blending fuels of different heavy fuel oil characteristics is only safe if viscosity ratios are tightly controlled. Lonnmeter’s inline monitoring guarantees that blended fuels remain within specification before they reach sensitive combustion equipment.

Benefits of Viscosity Control in Process

Improving Product Quality and Consistency

Tightly controlled fuel oil viscosity ensures predictable combustion performance, minimizing fluctuations that could harm production output.

Maximizing Production Efficiency and Throughput

By removing manual guesswork and delays, online viscosity control allows facilities to run at peak efficiency without interruptions caused by unstable combustion.

Reducing Energy Consumption and Operational Costs

Preheating fuel to just the right viscosity avoids excessive heating, saving fuel energy while protecting components from premature wear.

Meeting Environmental and Safety Regulations

Stable heavy fuel oil viscosity leads to cleaner burns with fewer unburned hydrocarbons, helping industries comply with emission limits while maintaining safe plant operation.

FAQs

What is the optimal viscosity for heavy fuel oil?

The optimal viscosity for heavy fuel oil at the engine injection point is typically between 10–15 centistokes (cSt), achieved through controlled preheating. This range ensures proper atomization, clean combustion, and reduced engine wear.

Why is viscosity important in fuel?

Fuel viscosity directly influences flow behavior, pumping efficiency, and atomization quality. If viscosity is too high, fuel fails to atomize properly, causing incomplete combustion and deposits. If too low, it may leak past injector seals and reduce pressure. Both extremes harm efficiency and equipment life.

How do heavy fuel oil characteristics affect viscosity?

Heavy fuel oil characteristics, such as density, asphaltene content, and blending ratios, directly determine viscosity. Higher molecular complexity leads to thicker, more resistant fuels that require precise heating and online control for safe handling.

How is fuel oil viscosity controlled in practice?

A fuel oil viscosity control system regulates viscosity by combining temperature adjustment (preheating) with real-time monitoring. Advanced systems like Lonnmeter provide continuous inline viscosity data, ensuring stable blending, optimized combustion, and compliance with ISO and IMO standards.

How does temperature affect fuel viscosity?

Fuel viscosity decreases as temperature rises. For heavy fuel oil viscosity, preheating to 120–150 °C is often necessary before injection. This ensures the fuel reaches the target viscosity window required for efficient atomization and clean combustion.

Advanced fuel oil viscosity measuring instruments, such as those developed by Lonnmeter, close the gap between fluctuating supply quality and stringent process demands. Contact us right now if you are confused with viscosity measuring to optimize combustion reliability, energy efficiency, and regulatory compliance.

Post time: Sep-05-2025