The modern cosmetic manufacturing industry is characterized by complex formulations, often comprising non-Newtonian fluids. The inherent rheological behaviors of these materials, such as shear-thinning and thixotropy, present significant challenges to traditional production methodologies, leading to batch-to-batch inconsistency, high raw material waste, and operational inefficiencies in critical processes like pumping and mixing. Conventional quality control methods, which rely on reactive, off-line viscosity measurements, are fundamentally inadequate for capturing the dynamic behavior of these fluids under production conditions.

I. Rheology and Fluid Dynamics in Cosmetic Production

The production of cosmetics is a nuanced process where the physical properties of the fluid are paramount. A deep understanding of these properties is a prerequisite for any meaningful discussion on process optimization. The fluid dynamics of cosmetic products are not governed by simple relationships, making them fundamentally different from Newtonian fluids like water.

1.1 Viscosity and Rheology

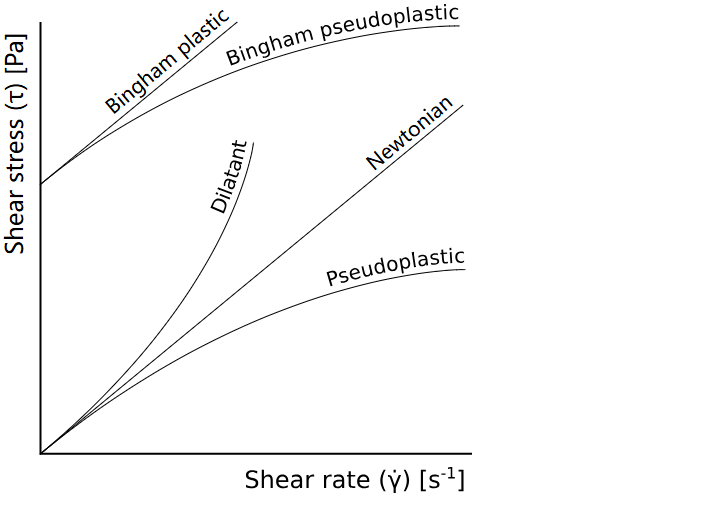

Viscosity is a measure of a fluid's resistance to an applied stress. For simple Newtonian fluids, this property is constant and can be characterized by a single value. However, cosmetic formulations are rarely this straightforward. Most lotions, creams, and shampoos are classified as non-Newtonian fluids, whose resistance to flow changes with the amount of force (shear) applied.

Rheology is the more comprehensive and essential discipline for this industry. It is the study of the flow and deformation of liquids, gels, and semi-solids. A single data point is insufficient to predict a product's behavior as it is pumped, mixed, and filled. The rheological characteristics of a product directly influence its sensory attributes, long-term stability in packaging, and functional performance. For example, the viscosity of a cream dictates its spreadability on the skin, and the consistency of a shampoo affects the amount a consumer dispenses from the bottle.

1.2 Non-Newtonian Fluids and Their Manufacturing Challenges

The complexity of cosmetic manufacturing stems from the diverse rheological behaviors of the fluids involved. Understanding these behaviors is key to addressing the underlying production challenges.

Pseudoplasticity (Shear-Thinning): This is a time-independent property where the apparent viscosity of a fluid decreases as the shear rate increases. Many cosmetic emulsions and lotions exhibit this behavior, which is desirable for products that need to be thick at rest but become spreadable or flowable when applied.

Thixotropy: This is a time-dependent shear-thinning property. Thixotropic fluids, like certain gels and colloidal suspensions, become less viscous when agitated or sheared over time and take a fixed amount of time to return to their original, more viscous state when the stress is removed. A classic example is non-drip paint, which thins under the shear of a brush but quickly thickens on a vertical surface to prevent sagging. Yogurt and some shampoos also demonstrate this property.

Yield Stress Fluids: These materials behave like a solid at rest and only begin to flow after an applied shear stress exceeds a critical value, known as the yield point or yield stress. Ketchup is a common example. In cosmetics, products with a high yield point are perceived by consumers as having "more volume" and a higher quality feel.

1.3 The Direct Impact on Process Efficiency

The non-linear behavior of these fluids has a profound and often detrimental effect on standard manufacturing operations.

1.3.1 Pumping Operations:

The performance of centrifugal pumps, which are ubiquitous in manufacturing, is significantly impacted by the viscosity of the fluid. A pump's head and volumetric output can be substantially "derated" when pumping high-viscosity, non-Newtonian fluids. Studies show that an increase in solid content in a mixture can lead to head and efficiency reductions of up to 60% and 25%, respectively, for concentrated mixtures. This derating is not static; the high shear rate inside the pump can alter the fluid's apparent viscosity, leading to unpredictable pump performance and a lack of consistent flow. The high resistance of viscous liquids also places greater radial load on bearings and causes problems with mechanical seals, increasing the risk of equipment failure and maintenance.

1.3.2 Mixing and Agitation:

In a mixing tank, the high viscosity of cosmetic fluids can severely dampen the flow stream from the mixing impeller, concentrating the shear and mixing action to a small region immediately surrounding the impeller blade. This leads to substantial energy waste and prevents the entire batch from achieving homogeneity. For shear-thinning fluids, this effect is exacerbated, as the fluid far from the impeller experiences low shear rates and remains at a high viscosity, creating "slow-mixing islands" or "pseudo-caverns" that are not properly homogenized. The result is an uneven distribution of components and an inconsistent final product.

The traditional approach of manual, off-line measurement of viscosity is fundamentally inadequate for managing these complexities. The viscosity of a non-Newtonian fluid is not a single value but is a function of the shear rate and, in some cases, the duration of shear. The conditions under which a lab sample is measured (e.g., in a beaker at a specific spindle speed and temperature) do not reflect the dynamic shear conditions within a pipe or a mixing tank. Consequently, a measurement taken at a fixed shear rate and temperature is likely irrelevant to the fluid's behavior during a dynamic process. When a manufacturing team relies on two-hour-interval manual checks, they are not only too slow to react to real-time process fluctuations but are also basing their decisions on a value that may not accurately represent the in-process state of the fluid. This dependency on flawed, reactive data creates a causal loop of poor control and high operational variability, which is impossible to break without a new, proactive approach.

Cosmetic Mixing & Blending

II. Sensor Selection and Hardware Implementation in Harsh Environments

Moving beyond manual methods requires the selection of robust, reliable online viscometers capable of providing continuous, real-time data from within the process.

2.1 Online Viscometry

Online viscometers, whether installed directly in the process line (inline) or in a bypass loop, provide real-time viscosity measurements 24/7, enabling constant process monitoring and control. This stands in stark contrast to off-line laboratory methods, which are inherently reactive and can only provide a snapshot of the process state at discrete intervals. The ability to obtain reliable, continuous data from the production line is a prerequisite for implementing an automated, closed-loop control system.

2.2 Essential Viscometer Requirements

The choice of viscometer for cosmetic manufacturing must be guided by the unique environmental and operational constraints of the industry.

Environmental and Durability Constraints:

High Temperature and Pressure: Cosmetic formulations often require heating to a specific temperature to ensure proper mixing and emulsification. The selected sensor must be able to operate reliably at temperatures up to 300 °C and pressures up to 500 bar.

Corrosion Resistance: Many cosmetic ingredients, including surfactants and various additives, can be corrosive over time. The wetted parts of the sensor must be constructed from highly durable, corrosion-resistant materials. 316L Stainless Steel is a standard choice for its resilience in such environments.

Immunity to Vibration: Manufacturing environments are mechanically noisy, with pumps, agitators, and other machinery producing significant ambient vibrations. A sensor's measurement principle must be inherently immune to these vibrations to ensure data integrity.

2.3 Analysis of Viscometer Technologies for Process Integration

For robust online integration, certain technologies are more suitable than others.

Vibrational/Resonating Viscometers: This technology operates by measuring the damping effect of the fluid on a vibrating element, such as a fork or resonator, to determine viscosity. This principle offers several key advantages for cosmetic applications. These sensors have no moving parts, which minimizes the need for maintenance and reduces overall operating costs. A well-engineered design, such as a balanced coaxial resonator, actively cancels out reaction torques and is therefore completely insensitive to mounting conditions and external vibrations. This immunity to ambient noise ensures a stable, repeatable, and reproducible measurement, even in turbulent flow or under high shear conditions. These sensors can also measure viscosity across an extremely wide range, from very low to very high viscosity fluids, making them highly versatile for a diverse product portfolio.

Rotational and Other Technologies: While rotational viscometers are highly effective in a laboratory setting for generating full flow curves, their complexity and the presence of moving parts can make them challenging to maintain in an inline industrial application. Other types, such as the falling element or capillary type, may be suitable for specific applications but often face limitations in measuring non-Newtonian fluids or are susceptible to temperature and flow fluctuations.

The reliability of an automated control system is directly proportional to the trustworthiness of its sensor input. Therefore, the long-term stability and minimal calibration requirements of the viscometer are not just convenience features; they are foundational requirements for a viable and low-maintenance control system. The cost of a sensor must be viewed not just as the initial capital expenditure but as its total cost of ownership (TCO), which includes the labor and downtime associated with maintenance and calibration. Data from instruments like capillary viscometers show that with proper handling and cleaning, their calibration can remain stable for a decade or more, demonstrating that long-term stability is an achievable and critical attribute of process instrumentation. A sensor that can maintain its calibration for extended periods significantly de-risks the automation project by removing a major source of potential process variation and enabling the system to operate autonomously with minimal human intervention.

| Technology | Principle of Operation | Suitability for Non-Newtonian Fluids | High-Temp/Pressure Capability | Corrosion Resistance | Vibration Immunity | Maintenance/Calibration |

| Vibrational/ Resonating | Measures fluid damping on a vibrating element (fork, resonator). | Excellent (high-shear, reproducible reading). | High (up to 300°C, 500 bar). | Excellent (all 316L SS wetted parts). | Excellent (balanced resonator design). | Low (no moving parts, minimal fouling). |

| Rotational | Measures torque required to rotate a spindle in the fluid. | Excellent (provides a full flow curve in a lab setting). | Moderate to High (varies by model). | Good (requires specific spindle materials). | Poor (highly sensitive to external vibration). | High (frequent cleaning, moving parts). |

| Capillary/ Differential Pressure | Measures pressure drop across a fixed tube at a constant flow rate. | Limited (yields a single average Newtonian viscosity). | Moderate to High (requires temperature stability). | Good (depends on material of capillary). | Moderate (flow-dependent, requires stable flow). | High (requires cleaning, susceptible to clogging). |

| Falling Element | Measures time for an element to fall through the fluid. | Limited (yields a single average Newtonian viscosity). | Moderate to High (depends on materials). | Good (depends on material of element). | Moderate (susceptible to vibration). | Moderate (moving parts, requires re-calibration). |

2.4 Optimal Sensor Placement for Accurate Data

The physical placement of the viscometer is as critical as the technology itself. Proper placement ensures that the data collected is representative of the process state. Best practices dictate that the sensor be placed in a location where the fluid is homogeneous and where the sensing element is fully submerged at all times. High points in the pipeline where air bubbles may accumulate should be avoided, as entrained air can disrupt measurements, especially for vibrational viscometers. Similarly, installation in "stagnation zones" where fluid is not in constant motion should be avoided to prevent material deposits from forming on the sensor. A good strategy is to place the sensor in a section of the pipe where the flow is stable and consistent, such as a vertical riser or an area with consistent flow rate, to provide the most reliable data for the control system.

III. Seamless PLC/DCS Integration via RS485

The successful deployment of an online viscometer relies on its seamless integration into the existing plant control infrastructure. The choice of communication protocol and physical layer is a strategic decision that balances reliability, cost, and compatibility with legacy systems.

3.1 System Architecture Overview

The standard industrial control architecture for this application is a master-slave relationship. The plant's central PLC or DCS acts as the "master," initiating communication with the viscometer, which functions as the "slave" device. The slave device remains "quiet" until it is queried by the master, at which point it responds with the requested data. This one-to-many communication model prevents data collisions and simplifies network management.

3.2 The RS485 Comminication Interface

The RS485 communication interface is a robust and widely adopted standard for industrial automation, particularly for applications requiring long-distance, multi-point communication.

Technical Merits:

Long-Distance and Multi-Drop: RS485 supports data transmission over distances up to 2000 meters, making it ideal for sprawling industrial facilities. A single bus can connect up to 30 devices, a number that can be expanded to 24/7 with the use of repeaters, significantly reducing the cost and complexity of cabling infrastructure.

Noise Immunity: RS485 employs a balanced, differential signaling approach over a twisted-pair cable. This design provides exceptional immunity to electromagnetic interference (EMI) and other electrical noise, which is a common problem in a plant environment with large motors and drives.

3.3 Bridging the PLC/DCS Gap

The RS485 is not simply a technical preference; it is a strategic business decision that significantly lowers the barrier to entry for process automation. Its ability to span long distances and resist noise makes it an ideal fit for industrial environments where these factors are more important than raw communication speed.

IV. Theoretical Derivation of Model-Based Adaptive Control

This section provides the rigorous intellectual foundation for a control strategy capable of handling the complex, non-linear dynamics of cosmetic fluids.

4.1 The Need for Advanced Control

Traditional Proportional-Integral-Derivative (PID) controllers are based on linear models of a process and are ill-equipped to handle the non-linear, time-dependent, and variable-property behaviors of non-Newtonian fluids. A PID controller is reactive; it waits for a deviation from the setpoint to occur before it begins to take corrective action. For a process with long response dynamics, such as a large mixing tank or a thickener, this can lead to slow error correction, oscillations, or overshooting of the target viscosity. Furthermore, external disturbances, such as temperature fluctuations or variations in incoming raw material composition, would necessitate constant manual re-tuning of the PID controller, leading to process instability and inefficiency.

4.2 Rheological Modeling for Control

The foundation of a successful control strategy for non-Newtonian fluids is an accurate and predictive mathematical model of their behavior.

4.2.1 Constitutive Modeling (First-Principles):

The Herschel-Bulkley model is a powerful constitutive equation used to describe the rheological behavior of fluids that exhibit both yield stress and shear-thinning or shear-thickening characteristics. The model relates shear stress (τ) to shear rate (γ˙) using three key parameters:

τ=τγ+K(γ˙)n

τγ (Yield Stress): The minimum shear stress that must be exceeded for the fluid to begin to flow.

K (Consistency Index): A parameter analogous to viscosity, representing the fluid's resistance to flow.

n (Flow Behavior Index): A crucial parameter that defines the fluid's behavior: n<1 for shear-thinning (pseudoplastic), n>1 for shear-thickening (dilatant), and n=1 for a Bingham plastic.

This model provides a mathematical framework for a controller to predict how a fluid's apparent viscosity will change under varying shear rates within the process, from a low-shear mixing region to the high-shear environment of a pump.

4.2.2 Data-Driven Modeling:

In addition to first-principles models, a data-driven approach can be used to build a process model that learns from the real-time data provided by the online viscometer. This is particularly useful for complex formulations where a precise first-principles model is difficult to derive. A data-driven model can adaptively adjust and optimize sensor parameters in real-time to account for external factors like changes in oil composition or temperature fluctuations. This approach has been shown to successfully control the average absolute error of viscosity measurements within a narrow range, demonstrating excellent performance and reliability.

4.3 Derivation of Adaptive Control Law

The core of a model-based adaptive control system is its ability to continuously learn and adapt to changing process conditions. The controller does not rely on fixed parameters but dynamically updates its internal model of the process.

Core Principle: An adaptive controller continuously estimates or updates the parameters of its internal model in real-time based on incoming sensor data. This allows the controller to "learn" and compensate for process variations caused by raw material changes, equipment wear, or environmental shifts.

Control Law Formulation:

Model Parameter Estimation: A parameter estimator, often based on a recursive least squares (RLS) algorithm with an adaptive forgetting factor, uses the real-time sensor data (viscosity, temperature, shear rate) to continuously tune the model parameters, such as the K and n values of the Herschel-Bulkley model. This is the "adaptive" component.

Predictive Control Algorithm: The updated process model is then used to predict the future behavior of the fluid. A Model Predictive Control (MPC) algorithm is an ideal strategy for this application. MPC can manage multiple manipulated variables (e.g., thickener addition rate and pump speed) simultaneously to control multiple output variables (e.g., viscosity and temperature). MPC's predictive nature allows it to calculate the precise adjustments needed to keep the process on track, even with long time delays, ensuring the fluid stays within its optimal rheological "window" at all times.

The transition from simple feedback control to model-based adaptive control represents a fundamental shift from reactive to proactive process management. A traditional PID controller is inherently reactive, waiting for an error to occur before taking action. For a process with significant time delays, this reaction is often too late, leading to overshoots and oscillations. An adaptive controller, by continuously learning the process model, can predict how an upstream change—such as a variation in a raw material's composition—will affect the final product's viscosity before the deviation becomes significant. This allows the system to make proactive, calculated adjustments, ensuring the product stays on specification and minimizing waste and variability. This is the primary driver for the massive reductions in batch variability and material waste documented in successful implementations.

V. Practical Implementation, Validation, and Operational Strategies

The final phase of a project is the successful deployment and long-term management of the integrated system. This requires meticulous planning and adherence to operational best practices.

5.1 Deployment Best Practices

The integration of online viscometry and adaptive control is a complex task that should be entrusted to experienced system integrators. A well-defined front-end design is critical, as up to 80% of project issues can be traced back to this phase. When retrofitting legacy control systems, a qualified integrator can provide the necessary expertise to bridge communication gaps and ensure a seamless migration. Furthermore, proper sensor placement is paramount. The viscometer must be installed in a location free of air bubbles, stagnation zones, and large particles that could interfere with measurements.

5.2 Data Validation and Reconciliation

For a control system to be trustworthy, the data it relies on must be validated and reconciled. Industrial sensors in harsh environments are susceptible to noise, drift, and errors. A control loop that blindly trusts raw sensor data is brittle and prone to making costly errors.

Data Validation: This process involves treating raw sensor data to ensure the values are meaningful and within the expected range. Simple methods include filtering out outliers and taking the average of several measurements over a defined time period to reduce noise.

Gross Error Detection: Statistical tests, such as the chi-square test, can be used to detect significant errors or sensor failures by comparing the value of the objective function to a critical value.

Data Reconciliation: This is a more advanced technique that uses redundant sensor data and process models (e.g., mass conservation) to produce a single, statistically validated set of data. This process increases confidence in the system and provides a self-aware layer of resilience to minor sensor anomalies and failures.

The implementation of a data validation layer is not an optional feature; it is a necessary intellectual component that makes the entire control system robust and trustworthy in the face of real-world inconsistencies. This layer transforms the system from a simple automation tool into a truly intelligent, self-monitoring entity that can maintain product quality without constant human oversight.

5.3 Long-Term Maintenance and Sustainability

The long-term success of an online viscometry system depends on a well-defined maintenance strategy.

Sensor Maintenance: The use of robust viscometer designs with no moving parts and corrosion-resistant materials, such as 316L Stainless Steel, can significantly mitigate the challenges of fouling and simplify maintenance routines.

System Calibration and Validation: Regular calibration is essential to ensure the long-term accuracy of the viscometer. For high-precision applications, calibration with certified viscosity standards should be performed on a scheduled basis, but the frequency can be reduced for less critical applications. As evidenced by long-term stability studies, some viscometer types, such as glass capillary or vibrational viscometers, can maintain their calibration for years, which significantly reduces the frequency of costly calibration events.

Actionable solution can deliver tangible benefits: a significant reduction in batch-to-batch variability and material waste, and a path toward fully autonomous, intelligent manufacturing. Start your optimization by contact Lonnmeter.

Post time: Sep-09-2025