Precise inline slurry density measurement keeps the thiosulfate gold leaching process stable, ensuring reagent dosing aligns with actual ore variations. Real-time data on slurry density and concentration directly affects ammonium thiosulfate leaching for gold by reducing under- and overdosing episodes. Inline meters enable fast adjustments to maintain current leaching rates, cutting variability within 3–5% and supporting recovery yields above 90% in optimized circuits.

Gold Leaching Solution

*

Inline Slurry Density Measurement: Industrial Process Overview

Non-cyanide gold leaching methods employ eco-friendly lixiviants such as ammonium thiosulfate and alkaline thiosulfate to extract gold from ores. The ammonium thiosulfate leaching process forms a soluble complex, promoted by copper(II) ions and stabilized by glycine under alkaline conditions, enabling gold dissolution with recovery rates exceeding 75% from refractory ores. Ore is finely crushed and pulped with water, creating a slurry. This slurry enters agitated leach reactors where reagent concentration, temperature, and pH are tightly controlled, maintaining optimal leaching conditions for gold extraction efficiency. Following gold dissolution, the pregnant leach solution (PLS) is separated from solids via filtration or thickening. PLS is processed for gold recovery using adsorption or precipitation, with resin-in-pulp and specialized activated carbon outperforming traditional CIP/CIL methods for thiosulfate systems. Inline slurry density measurement enables precise control of reagent addition and flow rates, crucial for optimizing pregnant leach solution analysis and recovery efficiency.

Gold Recovery from Ammonia-Thiosulfate Leaching Solution

*

Measurement Challenges

Non-cyanide gold leaching methods, such as thiosulfate gold leaching process and alkaline leaching techniques for gold extraction, present sharp variations in slurry density and solids content. Such fluctuations directly disrupt reagent addition and flow rate control, impeding consistent pregnant leach solution analysis and recovery. Slurries in these systems often exhibit non-Newtonian behavior, with shear-thinning characteristics and solids content exceeding 40% w/w in some thiosulfate leach operations.

Particle settling and sensor scaling are frequent. Lixiviants like ammonium thiosulfate and related by-products deposit on sensor surfaces, degrading real-time slurry density measurement. Multiphasic suspensions—with varying particle size distributions and gas entrainment—cause sensor drift and latency, complicating slurry density optimization in mining.

Rapid chemistry in non-cyanide leaching demands instant process feedback; even short delays can lead to suboptimal gold recovery. Feed ore mineralogy fluctuates hour-to-hour, introducing unpredictable density variation, which necessitates frequent slurry density meter calibration. These factors combine to make inline slurry density measurement techniques in non-cyanide circuits technically and operationally more challenging than in conventional cyanide leaching.

Benefits of Lonnmeter Inline Density/Concentration Meters

Lonnmeter inline density meters provide immediate, continuous measurement of slurry density in non-cyanide gold leaching methods, functioning accurately across variable particle sizes and ore mineralogies. Consistent monitoring stabilizes reagent concentrations, optimizing ammonium thiosulfate leaching conditions for sustained gold recovery.

Real-time density data enables precise dosage control, preventing overtreatment and reducing reagent consumption by up to 15% compared to batch methods. Operators detect and correct process drift instantly, stabilizing leach circuit performance and maximizing pregnant leach solution recovery.

Automated measurement reduces manual sampling frequency by over 80%, cutting exposure to hazardous slurries and lowering operator workload. Inline instruments maintain slurry density within ±0.001 g/cm³, ensuring tight parameter control essential for efficient gold dissolution and extraction.

Streamline Process Efficiency—Request a Quote

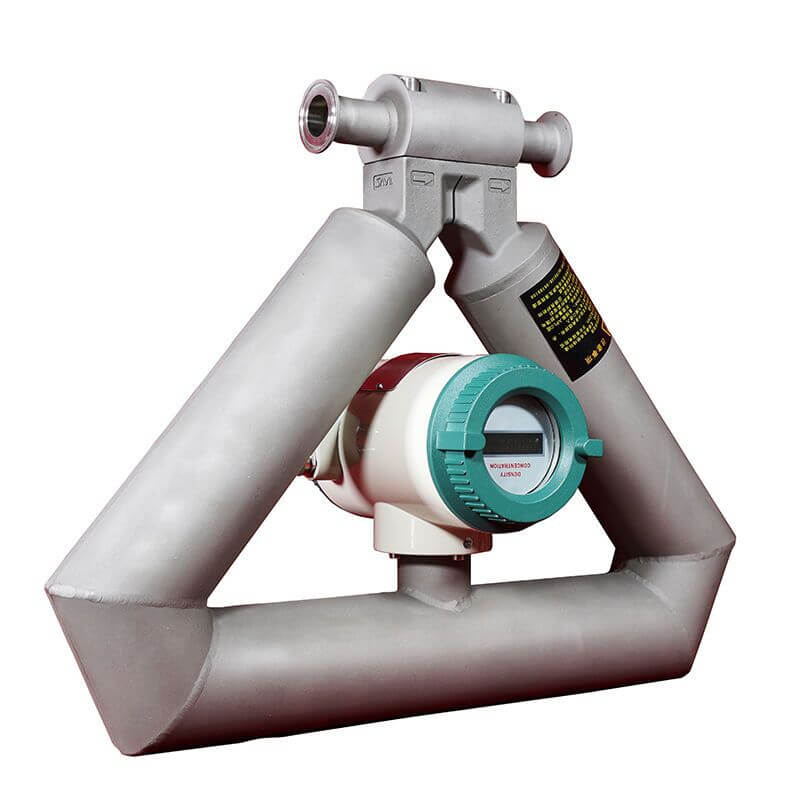

Lonnmeter inline density meters use ultrasonic transmission time to deliver real-time slurry density readings in non-cyanide gold leaching methods. Devices maintain slurry density fluctuations under ±0.001 g/cm³, supporting strict control in ammonium thiosulfate leaching and other alkaline leaching techniques for gold extraction. Inline measurement optimizes reagent dosing and prevents overdosing, lowering per-ton costs.

Operators monitor critical process variables—density, temperature, velocity—without manual sampling, reducing operator intervention and improving safety. Lonnmeter meters resist abrasion and mechanical wear, operating reliably under intense mineral processing conditions. Non-radioactive, explosion-proof construction ensures regulatory compliance and mitigates environmental risks in slurry density optimization in mining.

Higher gold yields result from precise pregnant leach solution analysis and recovery methods. Accurate slurry density measurement and calibration maximizes extraction efficiency, cuts reagent waste, and stabilizes recovery processes. Request us for quote if you came across similar problems.

Post time: Jan-22-2026