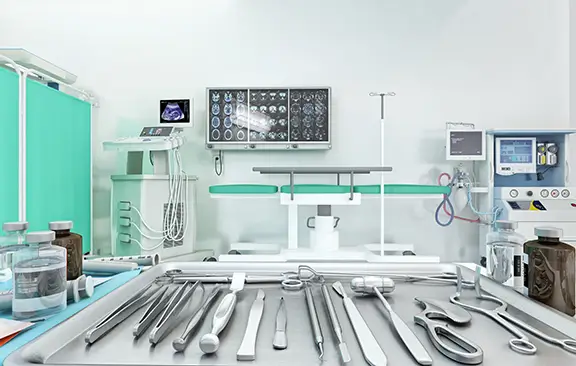

Medical device coatings play a pivotal role in advancing healthcare outcomes and patient safety. These coatings serve functions ranging from preventing infections and improving biocompatibility to enhancing the longevity of implants and surgical instruments. For example, antimicrobial coatings for medical devices actively inhibit microbial colonization, supporting infection control in clinical environments where hospital-acquired infections remain a major concern.

The primary challenges driving innovation in medical device coatings include:

- Infection Control: Devices must resist bacterial adhesion and biofilm formation. Advanced polymer coatings, including Antimicrobial Photodynamic Therapy and Nano Safe Coatings, are increasingly being deployed to mitigate infection risks in implants and wearable medical device coatings.

- Biocompatibility: Coatings must integrate seamlessly with human tissue, avoiding adverse immune responses while maintaining cellular tolerability. Silver-gallium matrices, for instance, are being clinically trialed for wound healing applications, highlighting the need for both biocompatible and antimicrobial properties.

- Device Longevity and Durability: Coatings should withstand repeated sterilization and constant mechanical stress. Options like scratch-resistant coatings and UV-resistant coatings for medical devices address these demands, ensuring lasting performance in high-use scenarios.

Emerging regulations—namely FDA and EU MDR requirements—are reshaping market expectations around safety, clinical evidence, and post-market surveillance for medical device surface treatments and coating techniques. The FDA’s recent de novo clearances of antibacterial implant coatings underline the importance of robust infection prevention while meeting regulatory benchmarks.

Evolving market demands include:

- Safer, more effective coatings for implants (including advanced solutions for cardiac and orthopedic devices).

- Cost-effective and environmentally sustainable technologies (such as biobased and biodegradable medical device coatings).

- Innovative nano-coatings in medical devices—offering precise control and responsive antimicrobial action with reduced risk of resistance.

Recent advances have introduced durable coatings for implants, hydrophilic and anti-fouling coatings for medical instruments, and sterile coatings for surgical tools. Market leading medical device coating manufacturers focus on scalable solutions—from blade-coating hybrid techniques for high-volume production to superhydrophobic coatings made with sustainable materials.

This article will systematically explore the landscape of medical device coatings: from infection control strategies and regulatory updates to nanotechnology breakthroughs, viscosity management, and advanced application methods.

The Foundations of Medical Device Coatings

1.1. Purpose and Importance

Medical device coatings are engineered surface treatments designed to enhance the safety, effectiveness, and lifespan of medical and surgical tools, implants, and wearables. These coatings serve several critical functions:

Antimicrobial Protection: Coatings such as silver, gallium, and nano-based solutions inhibit microbial colonization and help prevent device-associated infections. Devices with antimicrobial coatings see reduced infection rates; improper selection or absence can result in significant hospital-acquired complications and patient morbidity.

Friction Reduction: Hydrophilic and lubricious coatings are routinely applied to intravascular catheters, orthopedic appliances, and cardiac leads to lower friction. This reduces tissue trauma, eases insertion, and extends device life. For example, orthodontic archwires with advanced coatings demonstrate less wear and smoother movement.

Biocompatibility: Coatings such as advanced polymer films and oxide layers are engineered for biological compatibility. Biocompatible coatings for medical devices minimize adverse tissue reactions and ensure device safety over time, which is paramount for implants and long-term devices.

Chemical Resistance: Durable coatings like ceramic, parylene, and advanced polymer systems resist bodily fluids, cleaning agents, and disinfectants. Chemical resistance helps maintain function and sterility, supporting reprocessing in surgical instruments and exposure to harsh environments.

Durability: Scratch-resistant, UV-resistant, and wear-resistant coatings are crucial for both implants and high-use surgical tools. For example, UV-resistant coatings are sought for wearable medical device coatings, while scratch-resistant surfaces maintain the effectiveness of reusable medical instruments after repeated sterilization cycles.

Proper coating selection determines the device’s performance and safety. The right approach can lead to improved patient outcomes, reduced healthcare costs, and lower rates of infection or device failure. Improper selection—using coatings with poor adhesion, unsuitable biocompatibility, or inadequate resistance—can result in device recalls, increased replacement needs, and regulatory penalties. For example, the lack of effective coatings in urinary catheters raises infection risk, while advanced anti-fouling coatings for medical instruments reduce contamination and increase operational reliability.

1.2. Regulatory Landscape

Key Requirements and Standards

Regulatory bodies such as the FDA and the European Medicines Agency (via the EU Medical Device Regulation, MDR) enforce rigorous testing and documentation standards for medical device coatings.

FDA Standards:

- The FDA recognizes ISO 10993-1 for biocompatibility testing of medical device coatings, focusing on cytotoxicity, sensitization, and extractables.

- ISO 10993-17 (2023 update) expands toxicological risk assessment for leachables/extractables, requiring comprehensive safety data for new coating technologie.

- Standards such as ASTM E2149 and ISO 22196 measure antibacterial efficacy on coated surfaces.

EU MDR 2017/745:

- Emphasizes clinical evaluation and biocompatibility for coated and implantable devices.

- Requires continuous risk management and transparency in reporting clinical outcomes.

- Stipulates stringent classification and toxicity assessments for innovative coating techniques, such as nano-coatings in medical devices.

Recent Updates and Trends

FDA De Novo Clearances for Novel Antibacterial Coatings: In April 2024, the FDA granted De Novo clearances to two antibacterial-coated orthopedic implants. This approval was based on strong preclinical data, including a 99.999% in vitro bactericidal rate. The agency’s recognition highlights a shift toward infection-prevention technologies in high-risk patient groups, such as oncology and revision orthopedics.

Emerging Trends: There is a surge in nano-coatings in medical devices, providing dynamic antimicrobial action and enhanced wear resistance. FDA and EU regulators are increasing scrutiny, especially regarding antimicrobial resistance and environmental risks associated with nanoparticle-based technologies.

Innovation and Compliance: Regulatory updates mirror rapid advances in surface modification, including biodegradable medical device coatings, cost-effective solutions for implants, and innovative coatings for cardiac and dental applications.

Medical device manufacturers must keep up with evolving standards and demonstrate regulatory compliance for every coating used. This includes toxicological documentation, proof of safety and efficacy, and adherence to standardized test methods imposed by major regulatory agencies. Noncompliance can lead to device rejection, clinical failures, and risk to patient safety.

Examples of currently recognized coating types include:

- Biodegradable medical device coatings for temporary implants.

- UV-resistant coatings for wearable sensors.

- Advanced polymer coatings for medical devices enhancing flexibility and strength.

- Nano Safe antimicrobial coatings protecting against multidrug-resistant organisms.

These developments reflect a transition from generic surface treatments to tailored, evidence-based solutions marrying device performance with regulatory approval and patient safety.

Types and Technologies of Medical Device Coatings

2.1. Antimicrobial Coatings

Antimicrobial coatings for medical devices are designed to curb device-associated infections by functioning through two principal mechanisms: bactericidal and bacteriostatic. Bactericidal coatings destroy bacteria on contact or through sustained release of active agents, reducing pathogen count decisively. Bacteriostatic coatings inhibit bacterial growth and reproduction, slowing colony expansion and biofilm formation. The optimal clinical strategy often combines both to curb infection recurrence and persistent biofilms.

Popular Technologies:

- Silver-Enriched Coatings: Silver ions provide broad-spectrum antimicrobial action. Meta-analyses report 14% reduction in periprosthetic joint infections (PJI) after bone reconstruction. Silver oxide matrices, especially those blended into transparent silicate layers, deactivate viruses and bacteria effectively and rapidly—e.g., 99.3% SARS-CoV-2 and >99.5% MRSA reduction within one hour.

- Silver-Gallium Hybrids: These synthetic matrices offer improved healing and broad utility for wound sites. FDA IDE-approved clinical trials highlight their role in donor site wounds and infection management.

- Organosilanes: Surface-bound silane molecules create a covalent antimicrobial barrier, reducing biofilm formation for extended periods. Though long-term clinical data is emerging, in vitro efficacy and durability point to promise for chronic implant protection.

- Hybrid and Nanostructured Coatings (e.g., Silver-Graphene): These interrupt biofilm formation, with silver-graphene nanocomposites lowering biofilm biomass by 50–70%, enhancing retention after infection and supporting DAIR protocol success.

Engineering Approaches:

- Mechano-bactericidal Surfaces: Nanopillared coatings physically rupture bacteria by stretching and impaling, confirmed by reduced pathogen counts in vitro and electron microscopy.

- Simulation-Based Design: Optimizing nanoarchitecture improves interaction with both gram-positive and gram-negative species, guiding next-gen antimicrobial surface engineering.

Clinical Impact:

- Silver coatings help retain infected implants and reduce acute/chronic infection rates, supported by multicenter patient studies.

- Emerging FDA approvals validate the clinical relevance of hybrid antimicrobial coatings for diverse applications.

2.2. Low Friction and Lubricious Coatings

Lubricious coatings enhance device function, patient safety, and longevity. Hydrogels and fluoropolymers lower surface friction and minimize fouling, which is vital for indwelling and moving devices.

Key Technologies:

- Hydrogel Systems: Hydrogels like PMPC, PNIPAM, PVA, and chitosan provide self-lubrication and compressive strength. They mimic cartilage, making them ideal for joint replacements and vascular stents. Hydrogels resist protein and bacterial adhesion, extending device lifespan and lowering inflammation risk.

- Fluoropolymer Coatings: Fluoropolymers reduce surface energy and improve lubricity. Products such as ShieldSys™ SB exemplify industry-standard coatings for catheters, stents, and implantables, supporting controlled drug release and reducing fouling.

- Application Scope: Low-friction coatings are key for cardiac implants, catheters, and surgical tools requiring precise movement. Their biocompatibility is confirmed via cytotoxicity assays, supporting safe long-term use.

2.3. Chemically Inert and Barrier Coatings

Chemically inert barrier coatings prevent device degradation and immune response, vital for devices exposed to aggressive sterilization and body fluids.

Leading Materials:

- Diamond-Like Carbon (DLC): DLC has high hardness, low friction, chemical stability, and adaptability across substrates. Fluorine-doped variants improve anti-biofouling and wettability, supporting anti-fouling coatings for medical instruments and durable cardiac implants.

- Parylene: Parylene films are vapor-deposited, providing an impermeable biocompatible barrier. Used extensively for implantable electronics and cardiovascular stents, they resist body fluid penetration and most sterilization procedures.

- Silicon Dioxide: Thin silicon oxide layers serve as robust barriers, highly inert and optically tunable for devices requiring transparency or optical response.

Coating Strategies:

- Thin vs. Thick Layers: Thin films offer minimal interference with device dimensions and rapid coating cycles. Thick layers provide greater chemical resistance for harsh environments.

2.4. Advanced Nano-Based Surface Technologies

Nano-coatings leverage engineered nanoparticles and nanostructures for functional enhancements not achievable by conventional materials.

Innovative Methods:

- Nanoparticle Incorporation: Physical dispersion embeds AgNPs or other antimicrobial nanoparticles into polymer matrices, increasing both mechanical durability and antibacterial action.

- Covalent Bonding Techniques: Chemical functionalization creates stable, robust nano-coatings with superior wear resistance. For instance, UV-curable PVA derivatives covalently bind antimicrobial dyes, allowing photo-activated, cytocompatible surfaces for wound dressings and implant coatings.

- Durability Focus: Nano-enabled barrier and antimicrobial coatings survive repeated mechanical stresses and environmental exposures, critical for wearable medical device coatings and next-gen implantables.

Examples:

- Bioactive Nanostructures: Covalently bonded nanostructures assure anti-infective function for long durations.

- Nano Safe Coating: Commercial platforms offer scalable production of nanoparticle-infused surfaces for sterile surgical tools and anti-fouling healthcare devices.

This multidimensional approach to medical device surface treatments maximizes clinical outcomes, device protection, and regulatory acceptance through innovative, biocompatible, and cost-effective medical device coating technologies.

Viscosity Management in Medical Device Coating Processes

3.1. Why Viscosity Matters

Viscosity is the measure of a coating fluid’s resistance to flow, central to both the application and final performance of medical device coatings. Industrially, precise viscosity management allows for consistent production—controlling layer thickness and ensuring strong adhesion on surfaces from implants to surgical tools. Functionally, viscosity determines whether coatings will be uniform and defect-free, impacting durability, biocompatibility, and antimicrobial efficacy. Regulatory bodies, including the FDA, require strict quality controls; improper viscosity management risks non-compliance, leading to recalls and increased costs .

Application methods depend on viscosity:

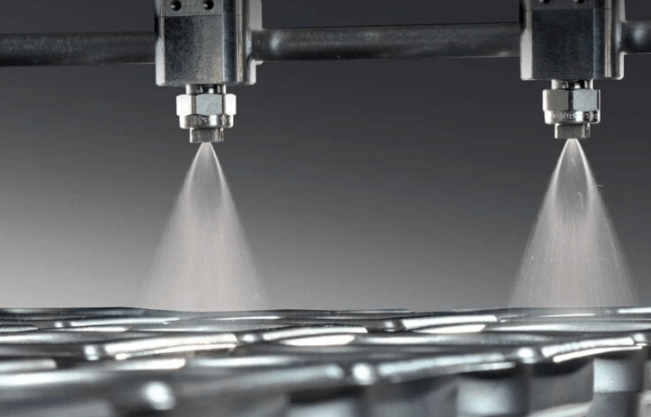

- Spray coating: Low to medium viscosity for atomization, critical for applying antimicrobial and durable coatings to implants or surgical instruments.

- Dip coating: Medium viscosity ensures uniform wetting and prevents sagging or run-off, important for hydrophilic coatings in healthcare devices.

- Brush or roll application: High viscosity required for even coverage on complex surfaces, like cardiac implants or wearables.

Correct viscosity also affects nano-coatings, improving performance for anti-fouling medical instruments, wearable devices, and biodegradable coatings.

3.2. Techniques and Analytical Tools

Modern viscosity management relies on real-time monitoring and control. Key tools include:

- Rheometers: Essential for detailed analysis of both simple and multi-component coating systems, assessing flow and viscoelastic properties. Used to measure the tunable viscoelasticity critical for direct ink writing and nano-enabled coatings .

- Inline viscometers and density meters: Integrated in automated manufacturing for continuous monitoring, minimizing human error, and ensuring coating uniformity .

- Optical coherence tomography (OCT): Enables non-contact, rapid viscosity measurement—valuable for sensitive and sterile environments such as the application of coatings to prevent infection .

- Microfluidic rheology: Allows precise control in small volumes, ideal for nano-based systems and advanced polymer coatings.

Best practices for managing multi-component and nano-enabled systems include:

- Precise formulation and temperature control: Adjusting polymer concentration, adding plasticizers, and regulating process temperatures to stabilize viscosity.

- Additive selection for nano-coatings: Use of polymeric modifiers (e.g., carboxymethylcellulose sodium) controls solvent evaporation and promotes nanoparticle alignment, supporting the uniformity in advanced bioactive and antimicrobial coatings .

- Automated process monitoring: With inline sensors, coating manufacturers can correct viscosity fluctuations instantly, improving both process efficiency and regulatory compliance.

Slip-stick concerns and microdomain uniformity are addressed by:

- Lubricious and hydrophilic coatings: Lower friction, prevent intermittent movement, and enhance device safety and user comfort—key for vascular devices and catheters

- Self-healing slippery surfaces: Advanced Teflon-based surfaces maintain lubricity over time, inhibiting biofilm and microbial growth.

- Ensuring even distribution of nano-components and polymer blends through tailored rheology prevents microdomain formation that can undermine durability and biocompatibility.

3.3. Troubleshooting Common Viscosity-Related Challenges

Medical device coating manufacturers face recurring defects due to improper viscosity management. Key challenges and strategies include:

Uneven Films & Run-Off

- Cause: Low viscosity leads to too thin, sagging, or dripping layers; high viscosity prevents uniform spreading.

- Solution: Inline viscosity sensors and process controls adjust formulation and temperatures dynamically for consistent film build.

- Cause: Poor dispersion and unstable viscosity during coating or drying phase.

- Solution: Additives like carboxymethylcellulose sodium and optimized polymer blends maintain nanoparticle separation and prevent clumping.

- Cause: Viscosity drops allow particulates or air bubbles to remain trapped; too high viscosity prevents contaminants from escaping.

- Solution: Routine inline monitoring, use of seal coatings, and controlled air flow in spray booths help minimize embedded contaminants.

- Cause: Viscosity fluctuations, especially in dense or nano-formulations, block fine spray nozzles.

- Solution: Regular temperature and concentration checks plus automated viscosity management systems maintain optimal flow and prevent clogs.

- Lab-scale formulations often behave differently at production scale due to equipment and environmental variations. Viscosity must be managed with:

- Automated process monitoring and feedback loops to dynamically correct viscosity issues.

- Precise control of batch temperatures and mixing rates to avoid inconsistency.

- Validated protocols for adjusting polymer ratios, plasticizer amounts, and nanoparticle concentrations for large-batch production of UV-resistant, scratch-resistant, and cost-effective device coatings.

Agglomeration of Nanoparticles

Embedded Contaminants

Spray Nozzle Clogging

Scale-Up and Automation

Advanced process monitoring, combined with formulation science, is vital to minimize coating defects on biocompatible, antimicrobial, and nano-enabled medical devices—ensuring durability, safety, and regulatory compliance.

Application Methods and Surface Bonding Strategies

4.1. Thermal, UV, and Hybrid Curing

Thermal curing, UV curing, and hybrid curing each serve critical roles in medical device coatings. Thermal curing employs heat to initiate polymerization or crosslinking. This method excels in producing durable coatings for implants and cardiac devices, routinely yielding strong mechanical properties and robust, biocompatible finishes. However, it may not suit heat-sensitive substrates or devices with intricate structures due to prolonged exposure and high process temperatures.

UV curing harnesses ultraviolet light for rapid, efficient curing via photopolymerization. This technique supports nanoscale coating deposition and is favored for hydrophilic coatings in healthcare devices, anti-fouling coatings for medical instruments, and antimicrobial coatings for medical devices, particularly where speed and energy efficiency are needed. UV curing enhances wearables, surgical tools, and nano-coatings on transparent or thin substrates, enabling scratch-resistant and anti-infection surfaces. Limitations emerge with opaque substrates or thick coatings, risking incomplete crosslinking.

Hybrid curing integrates thermal and UV processes or uses advanced photonic pulses for tailored performance. This approach leverages the rapid network formation of UV methods with the deep polymerization of thermal curing. Hybrid strategies help optimize biocompatible coatings, especially addressing the durability needs of advanced polymer coatings for medical devices. For example, sequential or simultaneous UV and thermal steps boost adhesion and mechanical resilience, supporting cardiac implants and wearables facing dynamic stresses.

Synergies between physical and chemical bonding mechanisms arise as these curing methods often promote intermolecular (physical) and covalent (chemical) bonds. For instance, UV curing amplifies photo-initiated crosslinking, while thermal or hybrid approaches enhance chemical crosslinks between coating and substrate, fostering long-lasting, reusable, and self-healing interfaces.

4.2. Surface Preparation and Functionalization

Effective medical device surface treatments begin with rigorous cleaning, activating, and priming. Plasma treatment employs ionized gases to sterilize and roughen surfaces, stripping biofilm and contaminants and increasing reactivity. Plasma-based cleaning dramatically improves adhesion and long-term performance, especially for titanium surfaces in implants, yielding superior resistance to peri-implantitis.

Laser processing enables precise, localized surface modification. By targeting micro-features, laser engineering enhances biocompatibility and can imbue surfaces with antimicrobial activity and wear resistance, critical for durable coatings and sterile surgical tools.

Silanization introduces reactive organosilane groups to substrates such as glass, metals, or polymers. This chemical priming step boosts hydrophilicity and creates anchor points for subsequent layers, essential for FDA approved medical device coatings and anti-fouling surfaces. Silanization is often paired with plasma activation to maximize coating adhesion and reduce delamination risks.

Optimally prepared surfaces ensure robust coating adhesion and device reliability. Inadequate cleaning or insufficient functionalization leads to poor mechanical performance, increased infection risk, and device failure. For example, plasma-treated stents demonstrate higher coating uniformity, while laser-engineered orthopedic implants show reduced bacterial colonization.

4.3. Thickness, Uniformity, and Device Suitability

Coating thickness and uniformity depend on device geometry, size, and substrate material. Complex geometries, such as those found in cardiac stents, orthopedic implants, or wearable sensors, challenge coating techniques for medical devices. Real-time monitoring—using technologies like SWCNTs—enables precise adjustment, ensuring even coverage and robust mechanical properties.

Substrate factors—metals (Ti, NiTi), ceramics (ZrO₂), polymers (PEBAX, Nylon)—directly influence the interaction with biomaterial coatings. High thermal conductivity or lattice mismatches can induce defects, uneven thickness, or weak adhesion. Magnetron sputtering of superlattice structures (TiN/TaN) and plasma spray composite coatings (zinc/silicon/silver/HAp) showcase tailored protocols for complex devices, delivering uniform, scratch-resistant, and biocompatible coatings even on convoluted surface topographies.

Precision in thickness and uniformity is critical for device suitability, patient safety, and regulatory acceptance. Advanced polymeric and nano-coatings in medical devices must maintain consistent barrier properties, resist delamination, and optimize anti-infection performance. Device manufacturers employ tailored plasma, UV, or hybrid processes alongside meticulous substrate selection and surface functionalization to meet stringent FDA requirements and clinical standards for innovative, cost-effective medical device coatings.

Performance, Safety, and Environmental Considerations

5.1. Evaluation and Testing

Robust evaluation of medical device coatings relies on advanced analytical techniques and standardized biocompatibility protocols. Atomic Force Microscopy (AFM) visualizes surface topography with nanometer-scale precision, revealing morphological changes and nanomechanical properties critical for performance and durability in biomedical applications. Scanning Electron Microscopy (SEM) provides high-resolution imaging of coating surfaces and interfaces, enabling analysis of microstructure, layer uniformity, and particulate distribution, which are vital for scratch-resistant and long-lasting coatings for implants and surgical instruments.

X-ray Photoelectron Spectroscopy (XPS) allows detailed surface chemical characterization, including elemental content and chemical states, essential for confirming the integrity of biocompatible coatings and chemical modifications used in hydrophilic or anti-fouling treatments. Inductively Coupled Plasma Mass Spectrometry (ICP-MS) quantifies elemental composition and mineral trace leaching, crucial for monitoring toxic metal release from biodegradable or nano-coatings and assessing batch-to-batch safety consistency in medical device surface treatments.

Standardized biocompatibility testing, following ISO 10993 protocols, includes cytotoxicity assessments, cell proliferation assays, hemocompatibility, and in vitro/in vivo performance evaluations. These regulatory frameworks ensure that advanced polymer coatings for medical devices are safe, efficient, and meet FDA requirements for clinical use. Examples include validation of silver-gallium matrices and microdomain polymer coatings, where both antimicrobial potency and host tissue safety are rigorously measured.

5.2. Infection Control and Antimicrobial Efficacy

Antimicrobial coatings for medical devices are designed to prevent biofilm formation and curb hospital-acquired infections (HAIs), addressing a major clinical challenge. Strategies utilize both chemical agents and engineered surface topographies. For example, coatings infused with silver ions, quaternary ammonium compounds, or gallium complexes exhibit broad-spectrum bactericidal activity against pathogens like E. coli and S. aureus, commonly implicated in device-associated infections.

Mechano-bactericidal surfaces, such as nanostructured metal-organic frameworks, physically disrupt bacteria, preventing colonization and biofilm development. Photodynamic coatings generate reactive oxygen species upon light activation, demolishing microbes without fostering resistance. Real-world performance is confirmed via multi-species microbial models and hospital environment trials, with documented reductions in microbial bioburden and HAI rates. Innovative coatings like Nano Safe use antimicrobial nanomaterials that self-sterilize high-touch medical devices and instruments.

5.3. Biocompatibility and Cytotoxicity

Successfully balancing antimicrobial efficacy with minimal cytotoxicity is critical for medical device surface treatments. High-potency agents, such as silver or gallium, must eradicate pathogens while sparing host tissues. Clinical studies on silver-gallium antimicrobial matrices for wound healing—FDA approved for human trials—demonstrate potent bacterial reduction but also undergo rigorous cytotoxicity and tissue compatibility evaluations.

Case examples include dopamine-silver nanocomposite coatings for dental implants, engineered to control silver release and minimize mammalian cell harm. Microdomain coatings with fluoropolymers combine anti-fouling properties with enhanced biocompatibility, used in sterile coatings for surgical tools and innovative cardiac implants. Multiple cell lines and standardized ISO 10993 cytotoxicity protocols are used to confirm safety, guiding medical device coating manufacturers in developing new materials.

5.4. Nanotechnology Safety and Environmental Impact

Nano-coatings in medical devices introduce unique safety and environmental risks. Nanomaterial leaching from implant or wearable medical device coatings can cause systemic exposure, initiating oxidative stress and inflammatory responses in tissues. Such risks necessitate advanced ICP-MS analysis for trace quantification and transformation monitoring.

Environmental persistence and ecological impact arise when nanoparticles migrate into water systems, potentially affecting aquatic organisms and bioaccumulation pathways. Regulatory frameworks lag behind technological advances, with gaps in environmental nanotoxicology assessments and lifecycle analysis of biodegradable and UV-resistant coatings for medical devices.

Device lifecycle management includes recycling strategies and remediation protocols to limit long-term ecosystem disruption. Regulatory compliance with international standards, ethical sourcing, and ongoing monitoring are recommended to ensure sustainable development of advanced medical device coatings. Future trends point toward harmonization of regulations, expanded nanomaterial tracking, and the introduction of green chemistry approaches in coating techniques for medical devices.

Real-World Applications and Emerging Solutions

Case Studies: From Implants to Diagnostic Devices

Infection Prevention in Long-Term Implantables

Infection remains a significant challenge for long-term implantable medical devices. Antimicrobial coatings for medical devices have advanced to minimize bacterial colonization and biofilm formation on device surfaces. Recent FDA de novo clearances for antibacterial implant coatings mark notable progress, with these surface treatments meeting rigorous clinical and regulatory standards for infection prevention . Material approaches include peptide-conjugated titanium coatings and nisin-based multilayer films, both engineered to disrupt bacterial adhesion and growth. These biocompatible coatings for medical devices target head implants, orthopedic hardware, and cardiac leads.

Anti-fouling coatings for medical instruments, such as Nano Safe Coating, add a layer of protection that inhibits microbial colonization while maintaining device function. These durable coatings for implants are particularly critical for long-term applications where infection risk and device longevity are paramount.

Enhancing Wear, Slip, and Patient Comfort

Wearable medical device coatings for both active and passive devices focus on more than infection: wear resistance, comfort, and optimal device interaction with tissue are essential. For active devices like catheters and endoscopes, lubricious hydrogel coatings reduce friction, minimalize tissue trauma, and resist microbial contamination. Advanced polymer coatings for medical devices incorporate hydrophilic, anti-fouling, and antimicrobial chemistries for dual benefit—low friction and reduced biofilm formation. Photothermal sterilization hydrogels exemplify innovative coatings for cardiac implants and vascular devices, where rapid, touchless sterilization further protects against cross-contamination.

For passive devices like silicone implants, scratch-resistant coatings for medical devices and UV-resistant coatings for medical devices preserve function and appearance through years of use. Hydrogel blends on silicone rubber—combining cytocompatibility, lubricity, and antifouling—have become standard in applications requiring long-term surface stability.

Recent Breakthroughs and Pipeline Technologies

Silver-Gallium Antimicrobial Matrices in Wound Healing

A recent FDA IDE clinical approval spotlights silver-gallium antimicrobial matrices, engineered for donor site wound care and infection control. These synthetic matrices deploy silver’s broad-spectrum antimicrobial action and gallium’s biofilm disruption in one platform. In vitro and early clinical data show efficacy against Staphylococcus aureus and Pseudomonas aeruginosa, two key pathogens in chronic wounds. Compared to conventional silver dressings, the silver-gallium composite offers improved biofilm inhibition without increasing cytotoxic risk.

Nanoparticle-Doped and Engineered Microdomain Coatings

Nano-coatings in medical devices utilize nanoparticles such as silver, copper, or PVDF integrated into microdomain patterns on device surfaces. Silver microdomain coatings on PEEK polymers, produced via excimer laser patterning, deliver antimicrobial ion release suitable for both bacterial control and osteogenic promotion . Diamond-like carbon coatings doped with silver and copper expand the antimicrobial spectrum while retaining mechanical durability, crucial for orthopedic and dental implants. PVDF nanoparticle coatings present unique advantages in promoting bone tissue integration, aligning with regenerative medicine goals. Characterization techniques—AFM, SEM, XPS—ensure precise control over functionality, release profiles, and cytocompatibility.

Examples:

- Silver microdomains on implantable PEEK demonstrated significant antibacterial activity against E. coli and S. aureus.

- Copper-doped diamond-like carbon applied to hip prostheses reduced infection and maintained wear resistance.

Role of Smart Manufacturing in Coating QC and Development

Smart manufacturing are reshaping how medical device coating manufacturers optimize workflows and quality control. Adaptive AI platforms accelerate new material discovery by up to 150% compared to conventional trial-and-error, vital for emerging bioactive and sterile coatings for surgical tools. Neural network systems generate efficient dispense paths for surface treatments, reducing manual input and computational burden, which enhances reproducibility and scalability. Smart manufacturing solutions, integrating AI and IoT, provide real-time analytics, process control, and cost-effective medical device coating production.

Examples include:

- AI-driven QC for scratch-resistant coatings, detecting microdefects and adjusting deposition in real time.

- IoT-enabled process monitoring for hydrophilic coatings in healthcare devices, offering predictive maintenance and consistent batch quality.

This convergence of advanced coating techniques for medical devices, durable and biocompatible materials, and digital manufacturing platforms underscores a transformative era in medical device surface treatments.

Conclusion

Guidance for Manufacturers and R&D Professionals

To stay ahead, manufacturers and R&D teams should:

- Proactively Monitor Regulations: Engage with authorities early, anticipate international harmonization requirements, and regularly review evolving FDA guidance, especially for nanotechnology and combination products.

- Prioritize Viscosity and Quality Control: Implement real-time, inline monitoring and environmental controls to ensure reproducible, defect-free coatings across diverse device portfolios.

- Advance Safety Assessments: Incorporate comprehensive biocompatibility, antimicrobial efficacy, and nanotoxicity testing for each new coating. Maintain transparency and traceability in all assessment protocols.

- Foster Innovation and Collaboration: Partner with materials scientists, clinicians, and regulatory consultants. Seek cross-functional insight to maximize the clinical relevance and safety of new coatings.

- Emphasize Patient Safety and Performance: Center development efforts on reducing infection, prolonging device lifespan, and enhancing biocompatibility. Adopt data-driven processes and feedback loops for continuous improvement.

These priorities lay the groundwork for a new era of biocompatible, durable, and adaptive medical device coatings. The ultimate goal: safer, longer-lasting, and patient-centered medical technologies for global healthcare systems.

Post time: Oct-28-2025