Inline sulfuric acid concentration measurement is essential for real-time sulfuric acid quality testing in industrial sulfuric acid manufacturing. Continuous inline concentration data deliver 0.1 % deviation in acid purity control, supporting strict sulfuric acid process control across all sulfuric acid production methods. Direct inline readings eliminate blind spots in manual sampling and increase copper recovery rates by up to 7% in copper ore hydrometallurgy.

Process reliability improves as acid dosing adjusts instantly to flow or feedstock changes, avoiding under- or overdosing during copper ore extraction process. This reduces acid waste generation by up to 12% and lowers operational costs related to chemical handling and disposal. Inline monitoring prevents equipment fouling and reduces the risk of acid-related leaks, which protects worker safety and ensures regulatory compliance.

Accurate inline sulfuric acid concentration measurement directly optimizes energy application in the copper ore leaching techniques, minimizing input while maximizing reaction efficiency and copper yield. Industrial sulfuric acid applications such as fertilizer and battery production demand 98%+ acid purity, maintained in real time with inline meters. Each of these benefits drives efficient, safe, and sustainable sulfuric acid production and copper leaching operations.

Copper Ore Leaching

*

Sulfuric Acid Production and Copper Ore Leaching

Modern industrial sulfuric acid manufacturing employs the contact process, structured for efficiency and purity. Sulfur is combusted in dry air, generating SO₂. This gas undergoes purification and is catalytically oxidized over vanadium pentoxide (V₂O₅) at 400–600 °C to yield SO₃. The SO₃ dissolves in concentrated sulfuric acid, producing oleum, which is diluted to achieve targeted acid strengths. Conversion exceeds 97%, with product purity routinely surpassing 98% H₂SO₄.

Copper ore leaching techniques rely on sulfuric acid as the primary chemical agent. In the copper ore extraction process, acid concentrations typically range from 0.5–2.0 M, with pH held at 1.5–2.0. Temperature control is critical, set between 25–55 °C to optimize copper dissolution and limit impurities. Well-calibrated sulfuric acid concentration meters support process control, ensuring efficient copper ore hydrometallurgy and reducing waste. Achievable copper recovery rates reach 90–93% for low-carbonate materials, aided by process optimization and continuous sulfuric acid concentration measurement.

Challenges of Inline Sulfuric Acid Concentration Measurement

Industrial sulfuric acid production process environments are highly corrosive. Sensor wetted parts degrade rapidly, especially above 70% sulfuric acid and at higher temperatures. Even alloys like titanium or PTFE coatings face pitting and cracking from impurities, with regular maintenance or replacement required. Direct inline measurement faces additional issues during rapid concentration swings—common in copper ore leaching techniques—when acid density and refractive index change nonlinearly, especially between 90–97% w/w. Sensor drift and lag risk missed process upsets.

Buildup from iron sulfate, silica, or copper ore leaching chemicals causes scaling or fouling on inline probes, reducing signal accuracy. Regular fouling on sensor surfaces drives up cleaning intervals and lowers productivity in sulfuric acid quality testing.

Temperature and pressure variation in industrial sulfuric acid manufacturing or copper ore hydrometallurgy directly affect measurement stability. Sulfuric acid density, viscosity, and refractive index are all temperature-dependent. Reliable sulfuric acid concentration meters require precise calibration for temperature compensation across dynamic process conditions. Manual sampling for sulfuric acid process control increases operator exposure risk and delays critical process adjustments.

Copper Heap Leaching

*

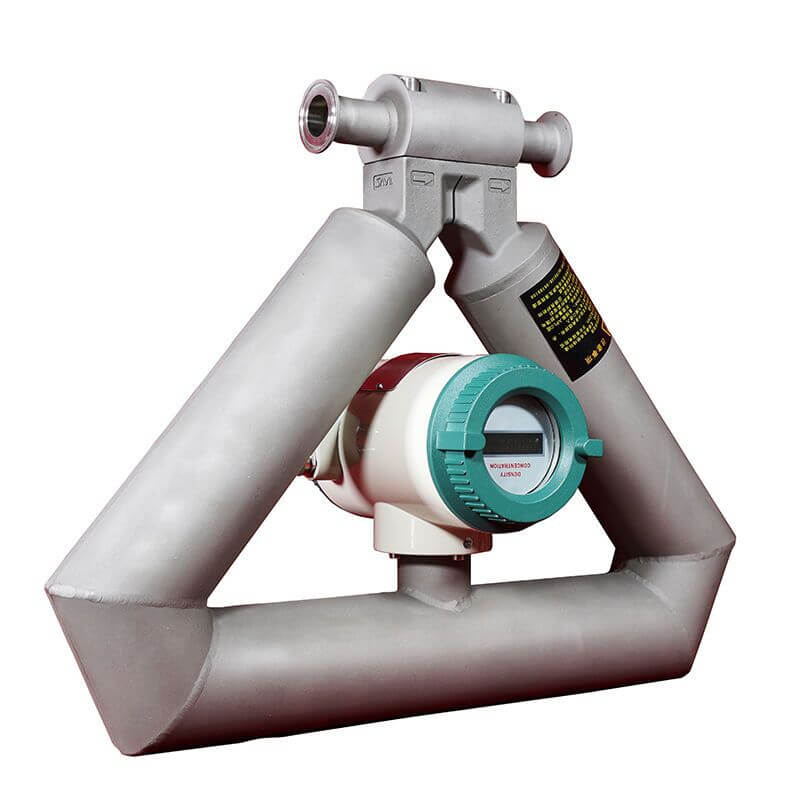

Benefits of Lonnmeter Inline Concentration Meters

Lonnmeter inline density and concentration meters deliver real-time outputs for sulfuric acid concentration measurement, enabling immediate sulfuric acid process control in industrial sulfuric acid manufacturing and copper ore leaching techniques. Accuracy reaches ±0.1% in concentration, eliminating manual sampling and direct operator contact with hazardous acids. This lowers exposure risks and meets strict industrial sulfuric acid applications safety standards.

Rugged, corrosion-resistant metallurgy—such as PTFE lining and Hastelloy components—ensures reliability and long instrument service life, even with aggressive copper ore leaching chemicals and in contact with concentrated acid streams. Inline deployment reduces maintenance intervals by over 60% compared with periodic lab testing, minimizing process downtime and scaling risks.

Lonnmeter meters enable optimal sulfuric acid dosing for copper ore hydrometallurgy, stabilizing concentration levels and reducing process variability. Automated, drift-free monitoring supports consistent acid blending, controlled evaporation, and precise sulfuric acid quality testing in the sulfuric acid production process. Consistent real-time data streamlines sulfuric acid concentration meter calibration cycles for reliable, repeatable sulfuric acid production methods.

Applications and Industrial Integration

Inline sulfuric acid concentration measurement underpins continuous process control in industrial sulfuric acid manufacturing for fertilizer, battery, and chemical sectors. In fertilizer production, over 60% of global sulfuric acid output drives phosphoric acid synthesis and phosphate fertilizer manufacture. Inline concentration meters verify ≥98% acid purity, safeguarding reaction efficiency and downstream product quality.

Lead-acid battery manufacturing requires tight sulfuric acid density range (1.285–1.300 g/cm³); inline density meters ensure electrolyte specifications and accelerate sulfuric acid quality testing. Battery recycling and metal recovery processes depend on accurate inline concentration measurement for efficient metal leaching and reduced chemical wastage.

Copper ore leaching techniques for hydrometallurgy utilize inline sulfuric acid concentration meters to regulate acid dosing—enabling precise copper ore extraction, minimizing acid consumption, and maintaining copper yield. Automated process integration with Lonnmeter inline concentration, density, and temperature transmitters stabilizes sulfuric acid production methods, cuttings costs and variability in continuous operation.

Hydrometallurgy circuits for copper recovery use Lonnmeter meters to monitor leaching chemicals, reducing manual sampling and operator risk. Frequent sulfuric acid concentration meter calibration ensures measurement reliability across all industrial sulfuric acid applications.

Request a Quote/Contact Section

Achieve precise sulfuric acid concentration measurement in industrial sulfuric acid manufacturing and copper ore leaching techniques using Lonnmeter’s inline instruments. Specify your sulfuric acid production process parameters, copper ore extraction process conditions, and target sulfuric acid concentration measurement range. Contact Lonnmeter for technical consultation and receive a custom quote tailored to your sulfuric acid process control and copper ore leaching requirements.

Post time: Jan-22-2026