Consistent quality is paramount for drug production in pharmaceutical manufacturing. The industrial crystallization process monitoring and control plays a pivotal role in achieving these goals, particularly in maintaining the purity, crystal form, and particle size distribution of active pharmaceutical ingredients (APIs). Crystallization monitoring, especially in the pharmaceutical industry, enables manufacturers to optimize processes, reduce costs, and meet stringent regulatory standards. With advanced technologies like ultrasonic crystallization monitoring, real-time data acquisition has transformed how pharmaceutical factories manage complex crystallization processes.

Importance of Crystallization Monitoring in Pharmaceuticals

Crystallization is a critical step in pharmaceutical manufacturing, used for the purification and formulation of APIs. The process determines the physical and chemical properties of the final drug product, including solubility, bioavailability, and stability. Inconsistent crystal size, shape, or polymorphism can lead to variations in drug efficacy, posing risks to patient safety and regulatory compliance. Pharmaceutical crystallization monitoring ensures that these properties are controlled in real time, minimizing batch-to-batch variability and ensuring high-quality output.

Challenges in Traditional Crystallization Processes

Traditional crystallization methods often rely on offline sampling and laboratory analysis, which introduce delays and increase the risk of errors. These approaches struggle to capture dynamic changes in the process like shifts in supersaturation. Additionally, manual interventions can lead to inefficiencies, higher energy consumption, and increased material waste. By adopting crystallization control strategies supported by real-time monitoring, pharmaceutical factories can overcome these challenges, achieving greater efficiency and cost savings.

Lonnmeter Inline Concentration Measurement for Crystallization Process Optimization

Integration with PLC or DCS Systems for Real-Time Control

Seamless integration into PLC or DCS system has revolutionized industrial crystallization process monitoring and control, enabling real-time monitoring over critical process parameters like concentration and temperatures. These technologies enable manufacturers to monitor crystal size, shape, and polymorphism without interrupting production, ensuring consistent quality. Additionally, the intelligent control system allows for precise adjustments to temperature, solvent composition, and mixing rates, optimizing the entire process.

Benefits of Ultrasonic Crystallization Monitoring

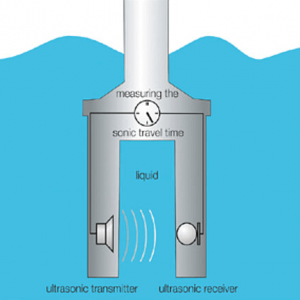

Ultrasonic crystallization monitoring stands out for its non-invasive, high-precision capabilities. Ultrasonic concentration sensors measure the velocity of sound waves through a liquid medium, correlating these measurements with concentration and crystal properties. This technology excels in dynamic environments, offering real-time data with response times as low as one second. Unlike traditional methods, ultrasonic monitoring is unaffected by factors like liquid color or conductivity, making it ideal for complex pharmaceutical processes.

Ultrasonic techniques also enhance nucleation and crystal growth by inducing cavitation, which creates uniform supersaturation and reduces induction time. This leads to more consistent crystal size and morphology, critical for pharmaceutical applications like lactose crystallization or API production.

The advantages of ultrasonic crystallization monitoring include:

- Real-Time Data: Immediate feedback on process conditions, enabling rapid adjustments.

- High Precision: Accurate measurements of concentration and crystal properties, with precision levels reaching ±0.05 m/s for ultrasonic velocity.

- Non-Invasive Operation: No need for sampling, reducing contamination risks and downtime.

- Versatility: Suitable for various pharmaceutical processes, from small-scale R&D to large-scale production.

By integrating inline concentration meters into crystallization systems, manufacturers can achieve crystallization control that maximizes yield, reduces energy consumption, and ensures regulatory compliance.

Practical Applications in Pharmaceutical Manufacturing

Optimizing Lactose Crystallization

In pharmaceutical production, lactose is commonly used as an excipient in tablet formulations. Controlling its crystallization process is essential to ensure consistent particle size and solubility. Pharmaceutical crystallization monitoring systems, particularly those using ultrasonic technology, have been successfully implemented to monitor lactose crystallization in real time.

Ensuring Polymorphism Control

Polymorphism, the ability of a compound to exist in multiple crystal forms, is a critical factor in pharmaceutical manufacturing. Different polymorphs can affect a drug’s dissolution rate and bioavailability. Crystallization monitoring via Lonnmeter ultrasonic concentration meter help identify and control polymorphic forms in real time. By maintaining optimal conditions, the inline process monitor ensures that the desired polymorph is consistently produced, reducing the risk of batch failures and costly rework.

Common Questions About Crystallization Monitoring (FAQs)

What Is the Role of Crystallization Monitoring in Pharmaceuticals?

Crystallization monitoring in pharmaceuticals ensures the consistent production of APIs with desired properties, such as purity, crystal size, and polymorphism. By providing real-time data, monitoring tools like ultrasonic sensors and PAT systems help manufacturers maintain optimal process conditions, reduce variability, and ensure compliance with regulatory standards.

How Does Ultrasonic Crystallization Monitoring Improve Efficiency?

Ultrasonic crystallization monitoring enhances efficiency by providing non-invasive, real-time measurements of concentration and crystal properties. It reduces induction time, minimizes energy consumption, and prevents batch failures by enabling precise control over nucleation and crystal growth.

What Are the Cost Benefits of Real-Time Crystallization Control?

Real-time crystallization process control reduces material waste, energy consumption, and downtime, leading to significant cost savings.

The industrial crystallization process monitoring and control is a game-changer for pharmaceutical manufacturing, offering unparalleled precision and efficiency. Crystallization control through real-time data not only enhances product quality but also streamlines operations, making it a critical investment for any pharmaceutical factory.

Contact our team today to explore advanced ultrasonic crystallization monitoring solutions tailored to your needs. Visit our website for a free consultation and discover how real-time monitoring can elevate your production efficiency and quality.

Post time: Jul-03-2025