Polymer melt viscosity measurement determines extrusion and molding process. Real-time viscosity monitoring is more important than temperature and pressure monitoring.

Overview of Extrusion Molding Process

Extrusion molding is a efficient manufacturing process in numerous industries for production of continuous profiles like pipes, films, sheets, etc. It enables production of complex cross-sectional shapes in consistent quality while guaranteeing high production speed and material efficiency. Obvious advancements like process automation, real-time monitoring and recycling process monitoring have improved precision and reduced environmental impact via waste reduction.

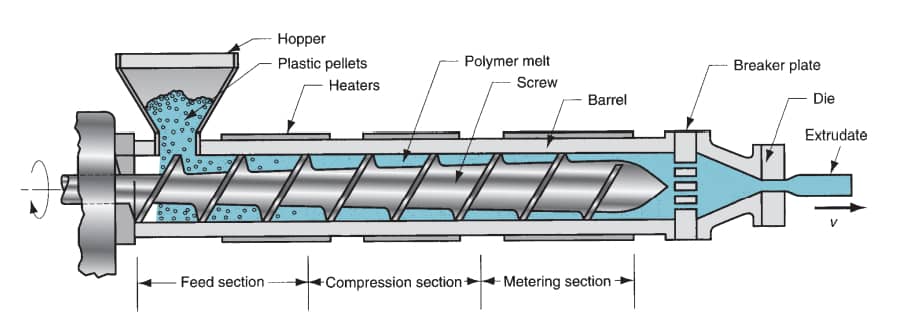

Rough Idea of Extrusion Machine

An extrusion machine consists of following parts: hopper, feeding screw, heating elements and gear pump. Material is fed into the machine at hopper. A continuously rotating feeding screw, driven by a motor and gearbox, moves material along a barrel and through a die. Heating elements along the barrel maintain controlled temperatures to soften and melt the polymer material. After exiting the die, the molten material enters a mold with one or more cavities, where it cools and solidifies into the desired shape. In some systems, a gear pump is placed between the barrel and die to ensure consistent pressure in the outgoing material.

Key Viscosity Measuring Points on an Extrusion Machine

Hopper Exit / Feed Zone: Measures initial melt viscosity as the polymer begins to soften.

Melting Zone (Mid-Barrel): Captures the transition to a fully molten state.

Metering Zone (Before Gear Pump or Die): Measures polymer melt viscosity measurement under operational shear rates.

Die Entrance: Provides real-time melt viscosity data at the point of extrusion.

Understanding Polymer Melt and Viscosity

What is polymer melt?

It is a polymer heated to a molten state, exhibiting flow properties that allow shaping through extrusion or molding. The melt viscosity of polymers—the resistance to flow—depends on molecular weight, temperature, shear rate, and additives, influencing the final product’s strength and finish. In the polymer extrusion process, where molten polymer is extruded through a die, and in injection molding, where it fills molds under pressure, maintaining optimal melt viscosity is vital. Traditional polymer melt viscosity measurement methods, such as off-line capillary rheometry, often lag due to delays, prompting the shift to inline viscometer for polymers for real-time insights.

Challenges in the Polymer Extrusion and Process Control

The polymer extrusion process and injection molding face significant hurdles in maintaining consistent melt viscosity. Variability due to thermal gradients and fluctuating shear rates can lead to uneven melt viscosity of polymers, causing defects like surface irregularities or voids in extruded profiles. Large-scale extrusion lines struggle with uniform polymer melt viscosity measurement across the flow, keeping compliance in process control. In high-speed injection molding, manual adjustments fail to keep pace with rapid cycle times, risking warpage or incomplete fills. These challenges underscore the need for advanced polymer viscometer systems, such as the automatic polymer viscometer, to provide real-time data and overcome the limitations of traditional methods.

Why Melt Viscosity Monitoring Matters

Melt viscosity measurement is pivotal in the polymer extrusion process and injection molding for several reasons. In extrusion, consistent melt viscosity ensures uniform die fill and prevents defects like surface irregularities or die swell. In injection molding, it affects mold filling, part quality, and cycle time, where variations can lead to warpage or incomplete fills. Real-time monitoring allows operators to adjust temperature, pressure, or material composition on the fly, optimizing energy use and reducing waste—key concerns as carbon regulations tighten in 2025.

The complexity of polymer melt viscosity measurement arises from the non-Newtonian nature of polymer melts, where viscosity varies with shear rate and thermal history. Systems of inline polymer-melt viscometer systems address this by providing continuous data, enabling process control that offline methods cannot match.

Lonnmeter’s Expertise in Melt Viscosity Monitoring

With over a decade of experience, Lonnmeter, a leading polymer viscometer supplier, has established itself as a pioneer in viscosity monitoring. Their expertise spans high-pressure, high-temperature extrusion lines and injection molding facilities, addressing the needs of diverse polymers like polyethylene, polypropylene, and PET.

Product Solutions

Lonnmeter offers cutting-edge polymer melt viscometer solutions tailored for melt viscosity monitoring. The Inline Viscometer is designed for perpendicular or parallel installation in extrusion machines, measuring melt viscosity up to 100,000 cP·s and temperatures up to 300°C, unaffected by flow variations.

Customization is a hallmark of Lonnmeter’s offerings, with options for threaded or flanged connections and data output via 4-20mA or RS485, integrating seamlessly with automation systems. In extrusion, the perpendicular setup ensures minimal flow disruption.

Benefits of Lonnmeter’s Melt Viscosity Solutions

Quality Assurance: Real-time polymer melt viscosity measurement ensures defect-free extrudates and molded parts.

Cost Efficiency: Reduced waste and maintenance lower operational costs.

Energy Savings: Precise adjustments optimize energy use.

Process Flexibility: Compatibility with various polymers supports diverse production needs.

Enhanced Safety: Early detection of viscosity anomalies prevents equipment strain.

FAQs

Why is melt viscosity more important than temperature or pressure?

Melt viscosity directly affects melt flow, die fill, and product consistency, often outweighing the influence of temperature or pressure. Proper polymer melt viscosity measurement prevents defects like warpage or die swell, making it critical for process control.

How does Lonnmeter ensure data integration?

The automatic polymer viscometer integrates via 4-20mA or RS485 protocols, offering real-time data to control systems. Its onboard historian, accessible via software, provides historical insights, surpassing traditional viscometer polymer limitations.

What factors influence the melt viscosity of polymers?

The melt viscosity of polymers is influenced by molecular weight, temperature, shear rate, and the presence of additives or fillers. Higher molecular weight and lower temperatures typically increase viscosity, affecting the polymer extrusion process.

Melt viscosity monitoring is a cornerstone of the polymer extrusion process and injection molding, ensuring quality and efficiency. With Lonnmeter’s proven expertise and advanced viscometer for polymers, manufacturers can overcome challenges in process control and optimize production. Request a quote today from this trusted polymer viscometer supplier!

Post time: Jul-31-2025