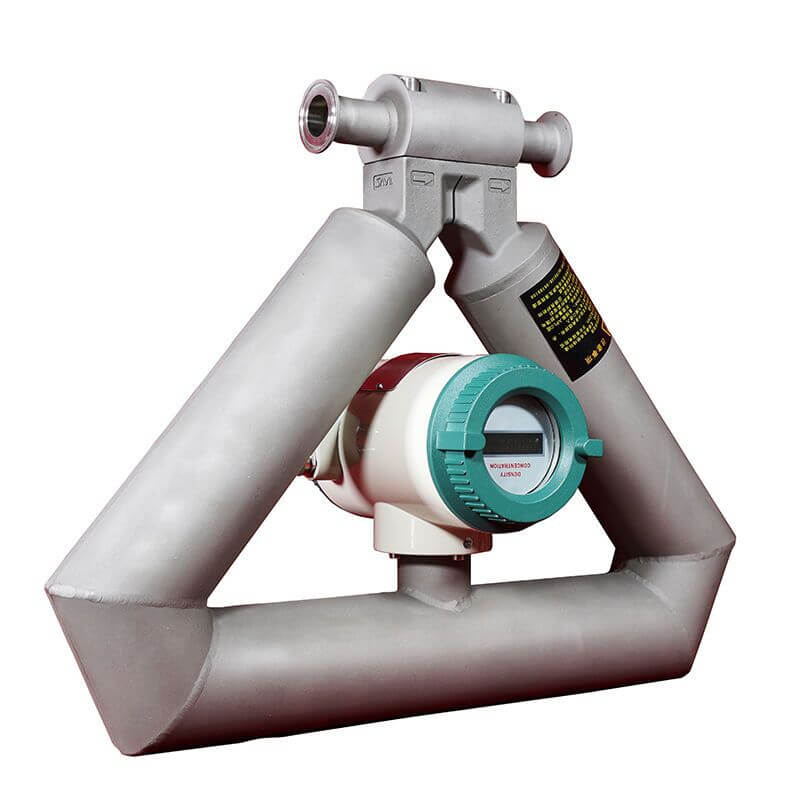

Inline density meters, such as the Lonnmeter tuning fork density meter, deliver precise in-process measurement of nitrocellulose lacquer formulations containing high boiling point solvents for industrial use. Real-time density monitoring maintains accurate solvent-to-resin ratios, directly impacting pigment dispersion quality, film gloss, and application consistency. For pigment dispersion techniques in coatings, maintaining density fluctuations within ±0.5% ensures optimal particle wetting and prevents batch-to-batch variation.

Rapid feedback reduces risk of off-spec lacquer due to solvent imbalance or pigment aggregation. High boiling solvents for polymer processing require close density control to avoid evaporation-rate mismatches and uneven film formation. Immediate data allows for swift correction—reducing rework, improving yield, and ensuring each batch meets gloss and flow requirements.

Nitrocellulose Lacquer

*

Introduction

Nitrocellulose lacquer relies on precise density control to achieve high gloss and consistent coating quality. Inline density meters, such as the Lonnmeter tuning fork density meter, directly monitor liquid measurement during mixing. Accurate readings maintain optimal solvent-to-resin ratios, especially with high boiling point solvents for industrial use. Effective pigment dispersion techniques—bead mills, high-speed dispersers, ultrasonic cavitation—demand rigorous solvent selection for pigment stability. Real-time adjustment of density provides uniform appearance, smooth film formation, and improved film gloss for automotive and furniture coatings. Industry studies show thin films of nitrocellulose lacquer, formed in multi-layer processes, deliver superior gloss and transparency. Inline density measurement enables immediate correction, reducing batch variation and supporting large-scale production.

Overview of Process Flow

Controlled reactors blend nitrocellulose with high boiling point solvents for industrial use, such as butyl glycol and dibutyl phthalate. Additives and plasticizers are incorporated to enhance flexibility and gloss. Solvent ratios are critical; true solvents dissolve nitrocellulose while cosolvents and non-solvents fine-tune viscosity and surface finish.

Pigment dispersion techniques for paint and coatings include high-speed dispersers, bead mills, and ultrasonic cavitation. These ensure even pigment loading, preventing agglomeration and supporting film stability. Optimized pigment dispersion improves film gloss in paint applications and coverage uniformity.

Viscosity and density are precisely controlled by adjusting the solvent concentration. Density meters for liquid measurement, including Lonnmeter tuning fork density meter, provide real-time values during mixing, ensuring the target flow and gloss.

Film formation is assessed inline for gloss, adhesion, and coverage, using measurement devices embedded in process lines. The final nitrocellulose lacquer formulation and uses are preserved by transferring through piping equipped with inline density meters for high gloss coatings with nitrocellulose lacquer. This delivers quality consistency from batch to batch.

acetonylacetone

*

Challenges in Inline Density Measurement

High boiling point solvents slow evaporation, causing rapid density signal fluctuations during nitrocellulose lacquer production. Industrial lines using solvents with boiling points above 140°C (e.g., xylene, butyl acetate) show up to 6% hourly density variance due to atmospheric, thermal, and flow rate changes.

Pigment dispersion techniques like bead milling and ultrasonic cavitation encounter micro-scale agglomeration; uneven loading shifts gloss quality, causing 3–15% variation in film appearance. Without real-time monitoring, pigment settling and cluster formation are undetected, directly impacting high gloss coatings.

During scale-up, maintaining uniform dispersion is difficult without inline concentration meters. Flow mixers increase output but amplify batch inconsistency risk when solvent selection or agitation energy changes. Conventional laboratory density meters—pycnometry or hydrostatic weighing—fail to correlate with real-time process fluid density shifts, especially in dynamic flows.

Process interruptions, equipment fouling, and residue buildup on sensor surfaces degrade data accuracy. Automated correction is necessary; manual readings delay response by up to 90 minutes per batch, leading to off-spec nitrocellulose lacquer formulation and uses.

Benefits of Integrating Inline Density Meters/Inline Concentration Meters

Real-time inline density and concentration meters deliver precise solvent-to-resin ratio control for nitrocellulose lacquer. This immediate, direct data ensures optimal pigment dispersion and prevents gloss drift caused by solvent imbalance—key when formulating with high boiling point solvents for industrial use. Inline measurement eliminates delays from manual sampling, which typically causes critical off-spec risks in pigment dispersion techniques for paint and coatings.

The Lonnmeter tuning fork density meter provides 24/7 direct in-line measurement, removing dependency on periodic lab verification. Instant density readings stop non-compliant batches before they proceed to filling—crucial for high gloss coatings with nitrocellulose lacquer and polymer processing that rely on exact solvent concentration.

Continuous monitoring enables prompt adjustment to solvent selection for pigment dispersion in response to real-time process variance. This guarantees batch-to-batch consistency, robust gloss control, and uniform film structure even during large-scale runs.

Request a quote for Lonnmeter inline density meter to control nitrocellulose lacquer formulation. Achieve precise adjustment of high boiling point solvents for industrial use, maintain optimum pigment dispersion techniques for paint and coatings, and maximize gloss with high gloss coatings based on nitrocellulose lacquer.

Post time: Jan-27-2026