Neutralization reactions, where acids and bases react to form water and salts, are critical across industries like chemical manufacturing, oil and gas, and mining and metallurgy. Precise control of chemical concentration in these processes ensures product quality, operational efficiency, and regulatory compliance. The Lonnmeter non-nuclear chemical density meter and chemical concentration meter provide real-time chemical concentration measurement, enabling industries to optimize the neutralization process.

These advanced tools address how to optimize neutralization process by delivering accurate data (±0.05-0.1% accuracy) for applications like oil neutralization process, wastewater treatment, and mineral leaching. Designed for chemical manufacturing plants, oil and gas industry facilities, and mining and metallurgy facilities, this article explores how chemical density meters and chemical concentration sensors enhance neutralization reaction processes, reduce costs, and ensure compliance, with a focus on key measuring points and data-driven solutions.

Why Chemical Concentration Matters in Neutralization

The neutralization process, also known as the neutralization reaction process, involves balancing acid and base concentrations to achieve a neutral pH (6-9), forming water and salts. In chemical manufacturing plants, precise chemical concentration measurement ensures consistent product quality, such as in the production of fertilizers or specialty chemicals. In oil and gas industry facilities, the oil neutralization process neutralizes acidic crude oil components to prevent corrosion and meet refining standards. Similarly, mining and metallurgy facilities rely on neutralization to adjust pH in leaching solutions for efficient mineral extraction.

Deviations in chemical concentration can lead to incomplete reactions, byproduct formation, or equipment damage. For example, in oil neutralization, maintaining 0.5-2 wt% alkali ensures effective acid removal without soap formation. Chemical density meters provide real-time data to maintain optimal concentrations, reducing waste and ensuring compliance with regulations like EPA or OSHA standards.

Challenges of Traditional Concentration Monitoring

Traditional methods like titration or offline pH testing for chemical concentration measurement are labor-intensive and fail to capture real-time fluctuations in dynamic neutralization reaction processes. These methods increase operational costs, delay adjustments, and risk non-compliance, especially in high-throughput environments like chemical manufacturing plants. Manual sampling struggles with variables like temperature, viscosity, or contamination, common in oil neutralization processes. Inline chemical concentration sensors, such as the Lonnmeter non-nuclear meter like Coriolis concentration meter, tuning fork concentration meter or ultrasonic concentration meter, address these challenges by offering continuous monitoring, enabling rapid adjustments to optimize the neutralization process.

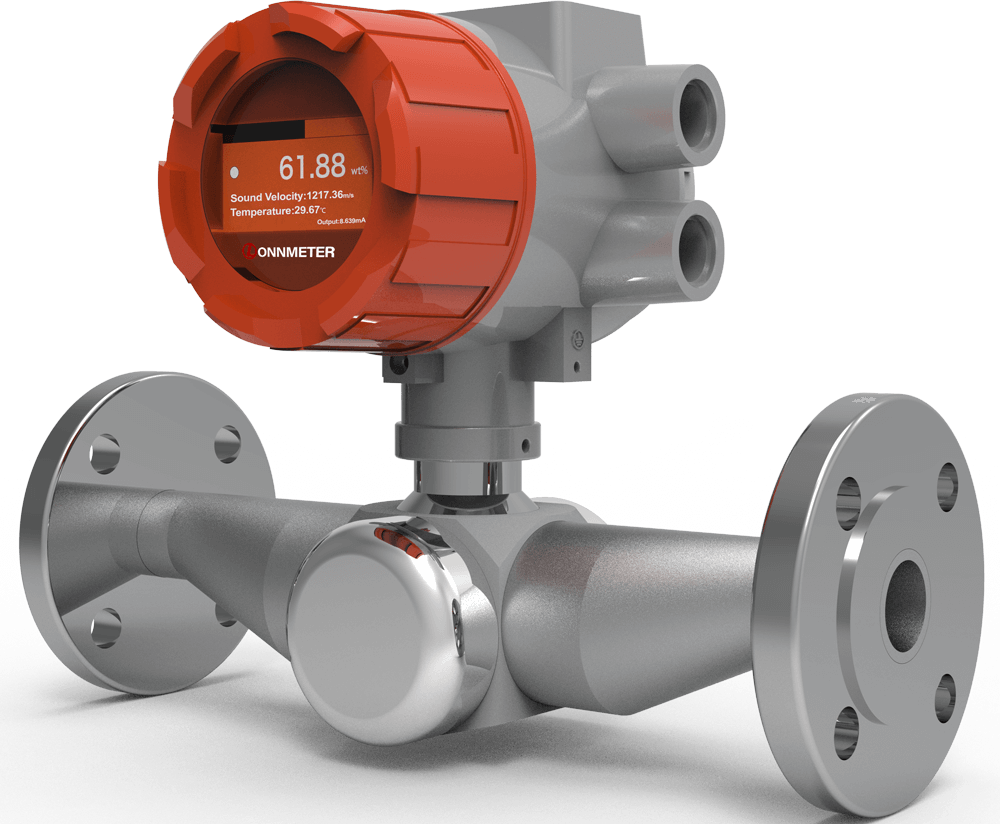

Lonnmeter Non-Nuclear Chemical Density Meter

The Lonnmeter non-nuclear chemical density meter revolutionizes chemical concentration measurement with advanced ultrasonic technology. It measures the speed of sound by calculating the transmission time of sound waves from source to receiver, deriving liquid density and calculating concentration at a standard 20°C with ±0.05-0.1% accuracy. This method is unaffected by liquid conductivity, color, or transparency, making it ideal for complex solutions in neutralization reaction processes.

In addition, two other Coriolis concentration meter, tuning fork concentration meter from Lonnmeter are also available to special operational environments. Please contact our engineers for more detailed info if you are interested.

Key Scenarios and Measuring Points for Inline Density Meters

Scenarios Requiring Inline Density Meters

Inline chemical density meters are essential in various neutralization scenarios, each requiring precise chemical concentration measurement to optimize outcomes:

Chemical Manufacturing

Neutralization produces salts or adjusts pH in chemical synthesis, such as sodium sulfate production. Precise chemical concentration ensures stoichiometric balance.

Neutralizes acidic components in crude oil refining to prevent pipeline corrosion. Alkali concentrations must be tightly controlled.

Adjusts pH in leaching solutions for efficient mineral extraction, such as copper or gold. Precise chemical concentration prevents reagent overuse.

Key Measuring Points in Neutralization Processes

To optimize the neutralization process, chemical density meters are deployed at critical measuring points like reactor inlet, reaction vessel, recirculation loop. So that to ensure consistent concentration and maintain stoichiometric balance and achieve neutral pH.

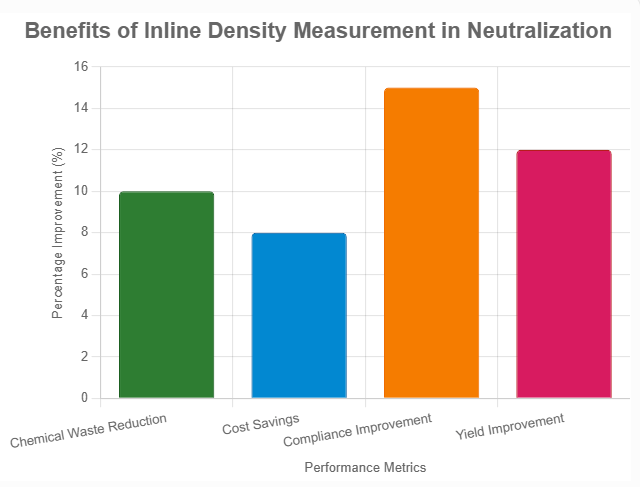

Key Benefits for Users

1. Enhanced Process Efficiency

2. Significant Cost Savings

3. Ensured Regulatory Compliance

4. Improved Product Quality

5. Simplified Automation and Integration

6. Robust and Low-Maintenance Design

FAQs About Chemical Density Meters in Neutralization

How Do Chemical Density Meters Optimize the Neutralization Process?

Chemical density meters provide real-time chemical concentration measurement, ensuring precise acid-alkali balance in neutralization reaction processes.

What Role Do Inline Meters Play in Oil Neutralization Processes?

In oil neutralization processes, chemical concentration sensors maintain alkali levels, preventing corrosion and soap formation, improving refining efficiency in oil and gas industry facilities.

How Do Inline Density Meters Ensure Compliance in Mining?

Inline density meters monitor chemical concentration in leaching solutions, optimizing pH and reducing reagent overuse, ensuring environmental compliance in mining and metallurgy facilities.

Chemical density meters and chemical concentration sensors, like the Lonnmeter non-nuclear inline density meter, are essential for optimizing neutralization processes in chemical manufacturing plants, oil and gas industry facilities, and mining and metallurgy facilities. By providing real-time chemical concentration measurement at critical measuring points, these tools address how to optimize neutralization process, reducing costs by 5-10%, improving yields, and ensuring compliance. From oil neutralization processes to wastewater treatment, the Lonnmeter meter delivers precision and efficiency, transforming neutralization reaction processes.

Contact Lonnmeter at www.lonnmeter.com for tailored chemical density meter solutions or request a free consultation today if you have any problems or confusion.

Post time: Jul-15-2025