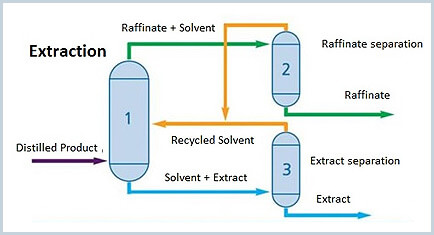

In the complex process flow of lubricating oil solvent refining, density control runs through the entire process of lubricating oil density measurement. The principle of extraction is used to separate non-ideal components from lubricating oil fractions. This method uses solvents such as furfural and phenol to achieve liquid-phase extraction under specific temperature conditions, mainly removing polycyclic short-side-chain hydrocarbons and sulfur/nitrogen-containing compounds.

The rich solvent phase containing non-ideal components and the relatively pure refined oil phase undergo preliminary separation in the extraction column, flowing out from different outlets respectively. The rich solvent phase enters the solvent recovery system, where the solvent is recycled through distillation and other methods; the refined oil phase enters subsequent processes such as stripping and drying to further remove residual solvents, obtaining qualified refined lubricating oil base oil.

Consequences of Density Measurement Errors

Excessive Residue of Non-Ideal Components

If the density control at the refined oil outlet is too high, the residue of non-ideal components will exceed the standard, significantly reducing the oxidation resistance and thermal stability of the lubricating oil. This will cause abnormal viscosity index, failing to meet the requirements of working conditions, and may even lead to equipment corrosion and environmental protection issues due to solvent residue.

Risk of Solvent Residue

Inaccurate density control may result in incomplete removal of solvents (such as furfural) in the refined oil. Solvent residues will corrode metal components. Especially in high-precision fields such as aviation lubricating oil, they may cause serious safety hazards such as seal aging and corrosion perforation.

Frequent Failures in the Solvent Recovery System

Abnormal density at the rich solvent outlet will lead to reduced fraction purity, weaken the solvent's extraction capacity, and form a vicious cycle. Water accumulation will cause solvent emulsification, requiring additional treatment. Impurities entering the system will also block equipment, wear components, and increase maintenance and downtime costs.

Crisis in Economic Benefits and Compliance

Inaccurate density control will increase costs such as product rework, solvent waste, and equipment maintenance, and may lead to penalties or even production suspension and rectification due to environmental non-compliance.

Extraction Column/Solvent Recovery System

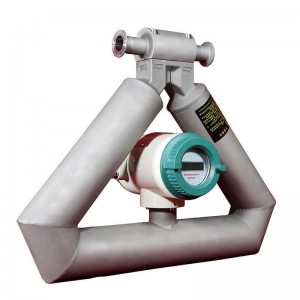

In the lubricating oil solvent refining process, the extraction column and solvent recovery system are core links. The precise monitoring and control of their density parameters directly affect product quality, production efficiency, and safety. As a real-time monitoring tool, the inline density meter can achieve dynamic optimization of key process parameters by continuously collecting fluid density data and linking with the control system. inline density meters are typically installed on the outlet pipeline of the refined oil at the top of the column and the outlet pipeline of the rich solvent at the bottom of the column.

Core Functions of inline density meters

Dynamic Adjustment of Solvent Ratio

If the density of the refined oil at the top of the column is too high (with more residual non-ideal components), the solvent injection volume will be automatically increased to improve extraction efficiency; if the density is too low (with excessive solvent), the solvent usage will be reduced to avoid waste.

Early Warning of Phase Separation Abnormalities

When "flooding" or "channeling" occurs in the extraction column, the densitometer data will fluctuate violently, and the system can issue timely alarms and adjust operating parameters (such as flow rate and temperature) to prevent production accidents.

Optimization of Extraction Column Load

By continuously monitoring density data, the material flow in the column is balanced to avoid local overload caused by uneven density and extend the equipment operation cycle.

Advantages of Lonnmeter Inline Density Meters

Lonnmeter inline density meters have stood out among products in the same industry with their strong performance and excellent adaptability after decades of market verification, providing reliable solutions for fluid density monitoring in various industries. Customers can select inline density meters with different precisions according to specific working conditions.

In terms of precision, Lonnmeter inline density meters have reached the top level in the industry, with some models achieving a precision of ±0.0005 g/cm³, far exceeding the average level of similar products. Customers can flexibly choose products with different precision levels according to specific working conditions, from the basic ±0.01 g/cm³ to the high-precision ±0.0005 g/cm³, to achieve the best balance between cost and performance.

For corrosive media, Lonnmeter offers a variety of corrosion-resistant materials, including Hastelloy, titanium alloy, and polytetrafluoroethylene, which can withstand the long-term erosion of strong corrosive media such as hydrochloric acid and sulfuric acid, greatly extending equipment service life and reducing maintenance costs.

Lonnmeter inline density meters support multiple installation methods, including side-mounted, top-mounted, and pipeline-mounted, which can perfectly adapt to the layout of various equipment and pipelines. At the same time, they are equipped with rich data interfaces such as 4-20mA, RS485, and Modbus, which can be seamlessly connected to control systems such as DCS and PLC to achieve remote monitoring and automatic control, helping enterprises improve production efficiency and intelligence levels.

In the field of lubricating oil extraction, precise density monitoring is the key to improving product quality and production efficiency. Lonnmeter inline density meters have helped many enterprises achieve efficient production with their multiple advantages.

If you are also seeking a more reliable density measurement solution, welcome to take action now! Click to initiate an inquiry to obtain a free detailed product catalog of Lonnmeter inline density meters, covering the full range of product parameters with different precision and materials to help you quickly select the right model; you can also unlock rich customer cases in the lubricating oil extraction industry to deeply understand how we solve density monitoring problems for enterprises and achieve cost reduction and efficiency improvement.

Post time: Jun-05-2025