Lubricants are utilized in extensive industries like automobile industry, chemical, construction, textile, infrastructure, agriculture, mining and oil drilling fortheir outstanding performance in wear resistance, lubricity and corrosion resistance. Flowabililty concerns like too-high or too-low viscosity may shorten equipment life and increase maintenance cost. Dive into more details with Lonnmeter find best solutions for precise continuous viscosity measurement in lube oil blending or manufacturing process line. Follow the trend of industrial automation process.

What Is the Viscosity Index (VI) of a Lubricant?

Viscosity Index (VI) is a critical measure that defines a lubricant’s ability to maintain consistent viscosity across a range of temperatures, a property essential for ensuring reliable performance in varied operating conditions. A high VI indicates minimal viscosity change with temperature fluctuations, making it ideal for applications like hydraulic systems or engines exposed to extreme climates. Conversely, a low VI lubricant experiences significant viscosity shifts, which can compromise performance. For instance, conventional mineral oils typically have a VI of 95–100, while highly refined mineral oils reach up to 120, and synthetic oils can achieve VIs exceeding 250.

Market Insights & Industrial Applications

All kinds of lubricants ought to deliver consistent performance even under extreme conditions. The lubricant manufacturing process is under increasing pressure to meet stringent quality standards, driven by rising demand for specialized products and shorter delivery times.

Lubricant blending and lubricant oil manufacturing processes rely heavily on precise control of lube oil density and viscosity to ensure product reliability. High viscosity lubricants excel in heavy-duty applications, while low viscosity lubricants are tailored for high-speed, low-load systems. Advanced lube oil viscosity meters enable manufacturers to meet these diverse requirements while ensuring optimal performance, reduced waste, and compliance with standards.

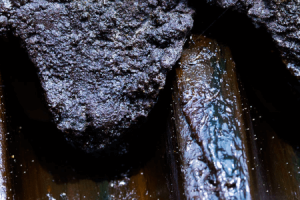

How Is the Viscosity Index of a Lubricant Determined?

Determining the Viscosity Index involves a standardized process. The formula for VI calculation is:

Where:

- U is the lubricant’s viscosity at 40°C.

- L is the viscosity at 40°C of a reference oil with VI = 0, matching the lubricant’s viscosity at 100°C.

- H is the viscosity at 40°C of a reference oil with VI = 100, matching the lubricant’s viscosity at 100°C.

For high-viscosity oils (kinematic viscosity at 100°C > 70 cSt), a modified logarithmic formula is used to ensure accuracy. This method allows manufacturers to quantify a lubricant’s temperature stability, ensuring it meets the specific needs of applications in the lubricant blending process.

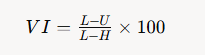

Lube Oil Blending & Manufacturing Process

The lubricant oil blending is a sophisticated process of raw material selection, mixing, and quality control. Base oils—mineral, synthetic, or semi-synthetic—are derived from crude oil refining through vacuum distillation, solvent extraction, and hydrofinishing to achieve desired properties like viscosity, viscosity index, and pour point. These base oils are combined with additives, such as viscosity index improvers, anti-wear agents, detergents, and antioxidants, to enhance performance characteristics like thermal stability and corrosion resistance. The lubricant manufacturing process involves:

- Base Oil Selection: Choosing mineral or synthetic oils based on application needs.

- Additive Integration: Incorporating additives like viscosity modifiers to tailor properties.

- Blending: Mixing in controlled conditions using large tanks with stirrers to ensure homogeneity.

- Quality Control: Testing for viscosity, density, flash point, and other parameters to meet standards.

- Packaging and Distribution: Bottling or barreling for market delivery.

This meticulous process ensures lubricants perform reliably in applications ranging from automotive engines to industrial machinery, with lube oil density and viscosity serving as critical quality indicators.

High Viscosity vs. Low Viscosity Lubricating Oil

The choice between high viscosity lubricating oil and low viscosity lubricating oil hinges on the application’s operational demands. High viscosity lubricants are ideal for heavy-duty applications, such as gear oils or greases used in construction equipment or steel industry bearings, where they:

- Form a robust protective film to reduce friction and wear under high loads.

- Enhance load-bearing capacity, supporting heavy machinery.

- Trap contaminants like dirt or metal debris, preventing surface damage.

- Maintain stability at high temperatures, ensuring reliable performance.

However, overly viscous lubricants can increase energy consumption and strain equipment. In contrast, low viscosity lubricants suit high-speed, low-load applications like automotive engines or hydraulic systems, offering:

- Improved flowability for efficient circulation and cold-start performance.

- Reduced energy consumption due to lower internal friction.

- Enhanced heat dissipation in high-speed systems.

Yet, low viscosity oils may fail to provide adequate protection under high loads, leading to wear.

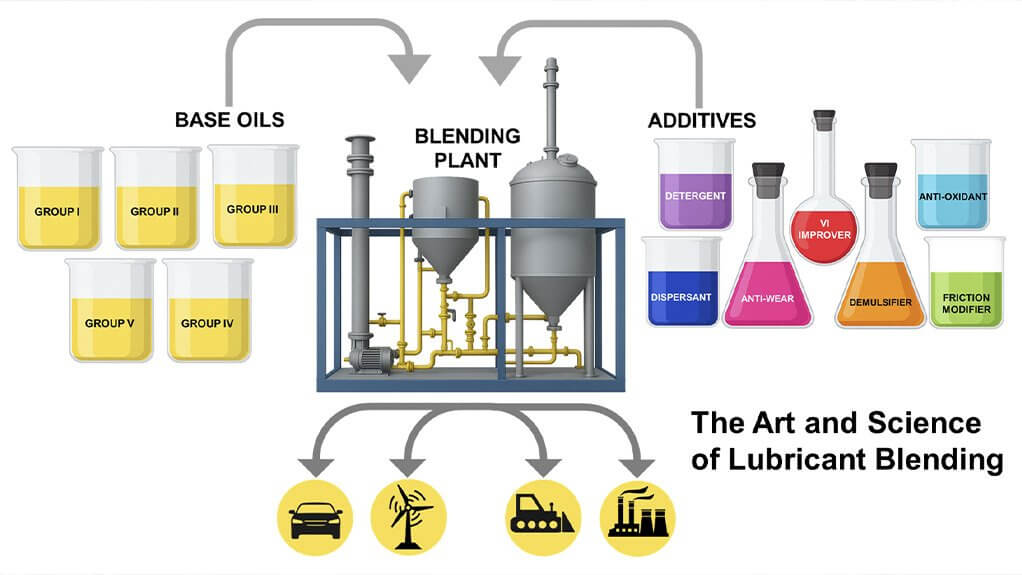

Operational Inefficiencies

Compromised Defoaming and Demulsibility: Leads to operational inefficiencies.

Increased Friction & Heat

Excessive thickness impedes flow, accelerating oxidation and forming varnish or sludge.

Risks Caused by Too High or Too Low Viscosity

Incorrect viscosity in lubricants can lead to significant operational challenges, mirroring issues seen in processes like the penicillin fermentation process where precise control is critical. High viscosity lubricating oil poses risks such as:

- Higher Energy Consumption: More power is required to overcome resistance, increasing costs.

- Poor Cold-Start Performance: Reduced pumpability risks equipment damage at low temperatures.

Conversely, low viscosity lubricating oil can result in:

- Inadequate Film Formation: Insufficient surface protection increases wear and component failure.

- Heightened Contamination Sensitivity: Thinner oils are less effective at trapping debris.

- Increased Friction and Heat: Promotes oxidation and reduces lubricant lifespan.

These risks underscore the need for precise lubricant oil blending process control using real-time viscosity monitoring to ensure consistent performance.

Value of Viscosity Measurement in Automation Process Line

Incorporating real-time viscosity measurement in blending into automated process lines transforms the lubricant manufacturing process, offering:

- Precision Blending: Ensures homogeneity, preventing off-spec batches and costly reblending.

- Cost Efficiency: Reduces energy use, slop oil production, and manual interventions.

- Quality Assurance: Maintains compliance with standards like ASTM D445, ensuring market acceptance.

- Process Optimization: Minimizes blending times while achieving uniform properties.

- Scalability: Supports seamless transitions from pilot to full-scale production.

- Proactive Issue Detection: Identifies contamination or mixing errors instantly, reducing downtime.

By automating viscosity control, manufacturers achieve just-in-time production, enhance flexibility, and meet the demands of a competitive market, akin to the precision required in continuous fermentation of penicillin.

Challenges with Traditional Process Monitoring

Traditional process monitoring in lubricant blending relies heavily on offline sampling and lab-based testing, such as the Saybolt Universal Viscometer, which presents significant challenges:

- Time Delays: Sampling and lab analysis introduce lags, hindering real-time adjustments.

- Inaccuracy: Temperature and shear variations during sampling compromise data reliability.

- Labor Intensity: Manual sampling increases operational costs and human error risks.

- Contamination Risks: Inconsistent sampling methods can introduce errors or cross-contamination.

- Limited Scalability: Offline methods struggle to keep pace with high-throughput production demands.

These limitations make traditional methods ill-suited for modern lube oil blending plants, where speed, accuracy, and automation are critical for maintaining competitiveness.

Importance of Real-Time Measurement in Blending

Real-time viscosity measurement revolutionizes the lubricant blending process by providing immediate, accurate data that drives efficiency and quality. Key benefits include:

- Elimination of Reblending: Continuous monitoring ensures on-spec blends, reducing waste and energy costs.

- Reduced Manual Interventions: Automation minimizes operator involvement, lowering costs and errors.

- Optimized Blending Times: Real-time adjustments prevent over- or under-mixing, saving time and resources.

- Logistical Efficiency: Onsite analysis reduces the need for off-site lab testing, cutting shipping costs.

- Environmental Benefits: Maximizes oil utilization, reducing waste and environmental impact.

- Enhanced Diagnostics: Tracks oil condition changes, enabling early detection of contamination or degradation.

Lonnmeter Product Solution: Lube Oil Viscosity Meter

Lonnmeter’s lube oil viscosity meters are engineered to meet the rigorous demands of lubricant oil manufacturing processes, offering cutting-edge solutions for real-time monitoring. Key features include:

- Wide Viscosity Range: Measures 10–10,000,000 cP, accommodating complex blends.

- High-Temperature Resilience: Operates up to 350°C, suitable for high-shear environments.

- Integrated Temperature Monitoring: Uses high-accuracy lube oil viscosity meter for precise temperature-compensated viscosity readings.

- Seamless Automation: Integrates with PLC and DCS systems for automated control.

- Robust Design: Compact, maintenance-free sensors with no consumables, ensuring reliability.

- Data Logging and Security: Automatically logs data with time codes, preventing unauthorized changes and enabling trend analysis.

Lonnmeter’s meters, similar to Rheonics’ SRV and SRD, provide inline viscosity and density measurements, eliminating the inaccuracies of traditional methods like the Saybolt viscometer. Their ability to handle non-Newtonian fluids ensures consistent quality in lubricant blending, supporting applications from formulation to final production.

Mastering viscosity control delivers consistent quality, reduce costs, enhance scalability, and ensure compliance with standards like ASTM D445. Contact Lonnmeter today to explore their state-of-the-art viscosity measurement solutions and transform your production process!

Post time: Aug-14-2025