In the dynamic world of LNG shipping, where precision and safety are paramount, real-time density monitoring is a critical component. As the LNG market continues to grow, driven by its environmental advantages and increasing demand for cleaner fuels, the need for accurate LNG density measurement has become more essential than ever. Liquefied natural gas (LNG), stored at -162°C, presents unique challenges due to its changing composition during LNG transportation. Lonnmeter’s innovative inline density meters address these needs, ensuring operational efficiency, safety, and compliance for LNG shipping companies.

The Need for Continuous Density Monitoring

Continuous monitoring of density is vital to prevent operational issues such as tank instability and inefficient pumping in LNG shipping. Fluctuations in density can lead to inaccurate cargo assessments, which may result in financial discrepancies or safety risks. For instance, variations in density can affect the stability of LNG storage tanks, potentially causing stratification that leads to dangerous roll-over accidents. Inefficient pumping due to unmonitored density changes can also increase operational costs and downtime. By employing real-time LNG density measurement, LNG shipping companies can ensure stable operations, minimize risks, and maintain efficiency across their fleets.

The Rapid Expansion of the LNG Market

The LNG market has seen remarkable growth over the past decade, driven by its environmental benefits as a transport fuel. LNG emits less noise and has a lower CO2 footprint compared to diesel, making it an attractive option for heavy-duty transport and industrial applications. Recent industry reports highlight that the global LNG market is expanding rapidly, with equal amounts of natural gas expected to be transported by pipeline and ship in the coming years. This growth underscores the importance of reliable measurement technologies to support the industry’s sustainability goals and meet the increasing demand for cleaner energy sources.

Importance of Accurate Density Measurements

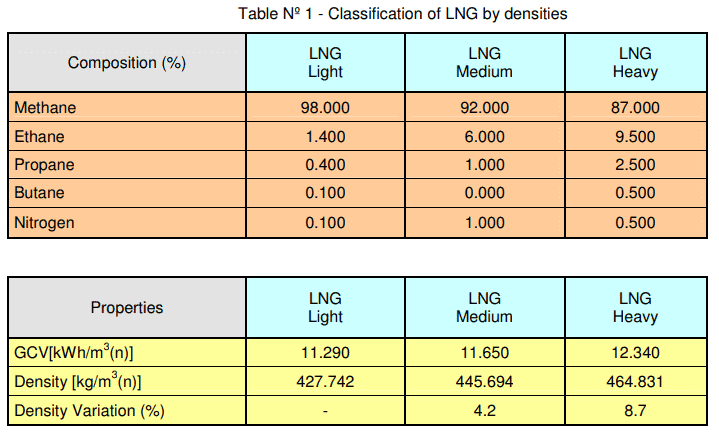

Accurate LNG density measurement is crucial for trading, shipping, and transporting LNG. Since LNG is traded based on its energy content, calculated from volume, density, and gross calorific value, precise measurements are essential for fair transactions and operational efficiency. High-speed, accurate density measurements are of significant commercial value, ensuring that traders and LNG shipping companies can confidently assess the energy transferred during custody transfer. Inaccuracies in density measurement can lead to financial losses, regulatory non-compliance, or operational challenges, highlighting the need for advanced monitoring solutions.

Challenges in LNG Density Measurement

LNG’s unique properties, including its extremely low temperature of -162°C and changing composition during LNG transportation, present significant challenges for density measurement. During shipping, LNG undergoes evaporation and compositional shifts due to temperature and pressure variations, which directly impact its density. These changes make metrological examination challenging, as traditional measurement methods may not account for the dynamic nature of LNG. For example, a lengthy ballast voyage can significantly alter the composition and density of LNG quantities, necessitating advanced, real-time monitoring solutions that can adapt to these conditions while maintaining accuracy.

Lonnmeter Inline Density Meters

With extensive experience in inline density measurement, Lonnmeter offers state-of-the-art inline density meters designed to meet the rigorous demands of the LNG shipping industry. These meters are engineered to deliver high-speed, accurate, and reliable density measurements, even under the extreme cryogenic conditions of LNG. Constructed with robust materials such as stainless steel, hastelloy, titanium, or tantalum, Lonnmeter’s meters ensure durability and performance in harsh environments. By integrating these LNG density meters into pipelines via flange, clamp, or direct insertion, LNG shipping companies can achieve continuous density monitoring, ensuring compliance with industry standards and optimizing operational efficiency. For more details, visit Lonnmeter’s density meters page.

Preventing Roll-Over Accidents

One of the most critical applications of density monitoring in LNG shipping is preventing roll-over accidents in storage tanks. Roll-over occurs when warmer, less dense LNG floats on top of denser, colder LNG, leading to rapid vaporization and potential tank rupture. Continuous density profile monitoring using Lonnmeter’s inline density meters can detect early signs of stratification, allowing operators to take preventive measures. By maintaining a stable density profile, these meters play a key role in averting catastrophic failures, enhancing safety, and protecting valuable assets during LNG transportation.

Common Questions About LNG Density Measurement

Why is density measurement important in LNG shipping?

Density measurement is fundamental for accurate cargo quantification, safe LNG transportation, and precise energy content assessment. It ensures that the energy content of LNG is correctly evaluated, which is critical for financial transactions, operational safety, and compliance with trading standards.

How does the composition of LNG change during transportation?

During LNG shipping, LNG can experience evaporation and compositional shifts due to temperature and pressure changes. These variations alter the density of LNG, necessitating real-time monitoring with tools like LNG density meters to maintain accuracy in measurements and ensure safe operations.

What sets Lonnmeter’s density meters apart?

Lonnmeter’s inline density meters are engineered to withstand extreme conditions, including the cryogenic temperatures of LNG. They provide high-speed, accurate measurements with real-time data transmission, making them ideal for the demanding requirements of the LNG shipping industry.

Real-time density monitoring is indispensable for the modern LNG shipping industry. It ensures operational efficiency, safety, and compliance with industry standards while supporting the industry’s commitment to environmental sustainability. Lonnmeter’s advanced inline density meters are at the forefront of this technology, offering solutions that meet the highest standards of accuracy and reliability. By investing in such cutting-edge technology, LNG shipping companies can navigate the complexities of the LNG market with confidence, knowing their operations are supported by state-of-the-art monitoring solutions. To explore how Lonnmeter can enhance your LNG transportation operations, visit Lonnmeter’s website or contact their team today.

Post time: Jul-22-2025