In the steel industry, maintaining optimal performance during the steel pickling process is crucial for removing oxide scale and heat tint, ensuring high-quality stainless steel parts. However, traditional pickling metal process methods, relying on chemical treatments like hydrochloric (HCl) or sulfuric acid, often suffer from inconsistent results due to degrading acid solutions and lack of real-time monitoring. This leads to inefficiencies, high reject rates, and costly EPA compliance challenges.

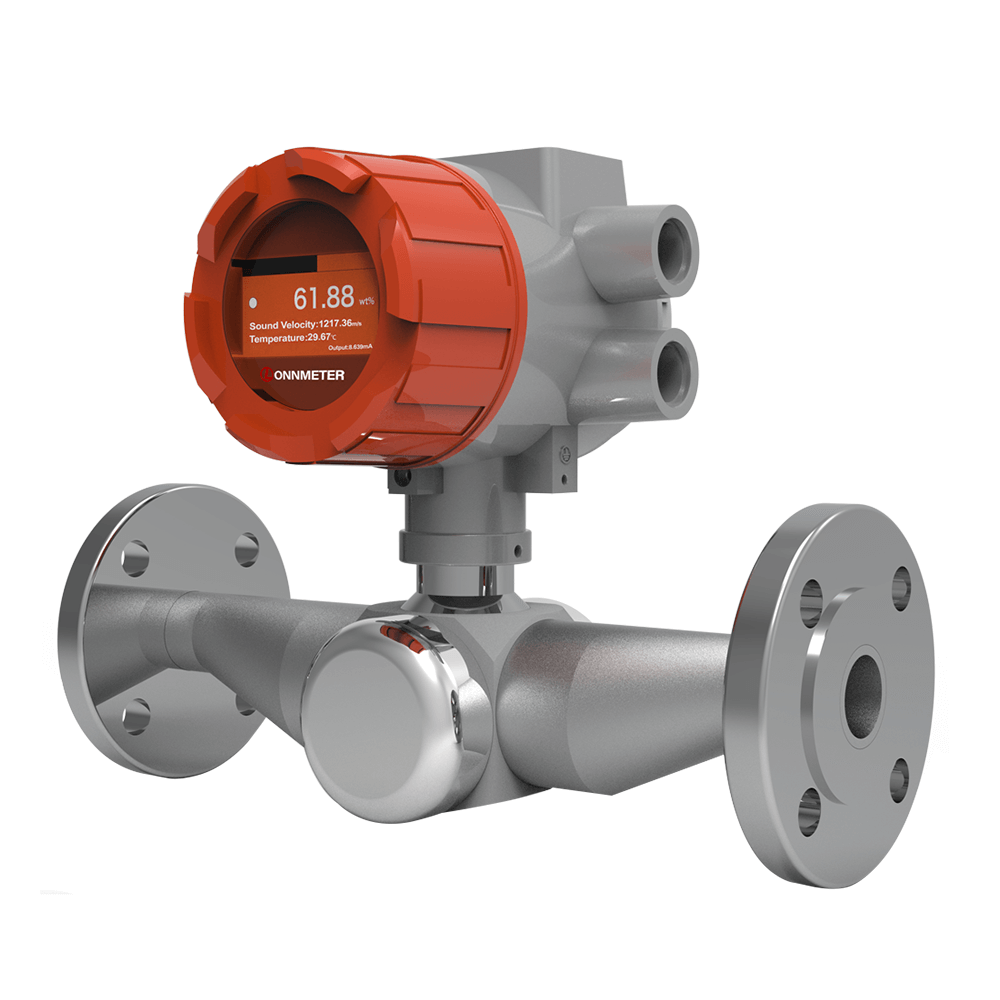

Lonnmeter inline acid density meter is a game-changer that uses ultrasonic technology for continuous acid density measurement online. Designed for steel pickling plants and technicians, this acid density meter inline offers drift-free precision, acid-resistant materials, and seamless automation integration. It’s meaningful step in improving quality and efficiency for steel production enterprises, non-ferrous metal processing plants, bearing and fastener production facilities, electroplating plants, anodizing production lines, wafer fabrication plants, printed circuit board (PCB) factories, chemical equipment manufacturers, metal recycling and regeneration plants.

Technical Know-How

While passivation enhances the corrosion resistance of stainless steel components, it falls short of addressing certain manufacturing imperfections. For instance, it does not eliminate heat tint or oxide scale resulting from welding and heat treatment processes. Historically, these issues have been tackled through an additional chemical procedure known as “pickling.”

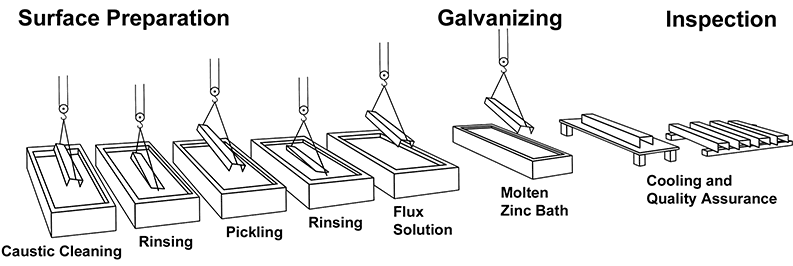

How Stainless Steel Pickling Works

Pickling serves as a pre-passivation treatment, where stainless steel parts are immersed in an acid solution—typically hydrochloric or sulfuric acid—to dissolve oxide scale, heat tint, and embedded steel particles. However, this pickling process of steel is inherently imprecise, presenting challenges such as stringent EPA regulations and inconsistent outcomes. As the acid solution ages, its effectiveness diminishes, and the extent of material removal can vary significantly, complicating efforts to maintain uniform quality in the steel pickling process.

Key Challenges in Inline Pickling Bath Monitoring

Inline pickling bath monitoring is a critical aspect of the steel pickling process, yet it comes with several pain points that can hinder efficiency and quality in pickling metal process and HCL pickling process. One major challenge is the lack of real-time data, as traditional methods like manual sampling and offline lab analysis (e.g., titration) introduce delays of 10-30 minutes. This lag often results in over-pickling, causing hydrogen embrittlement in high-strength steel, or under-pickling, leaving oxide scale intact and increasing reject rates by up to 15%.

Another significant issue is the degradation of acid solutions over time. The corrosive nature of pickling baths also poses a risk to monitoring equipment, with traditional sensors like glass density meters succumbing to damage, necessitating frequent replacements and maintenance, which may result in cost increasing in chemical pickling process thousands annually.

Environmental compliance adds further complexity, as EPA regulations demand strict control of acid mist and waste disposal. Inaccurate monitoring can lead to violations, incurring fines and complicating waste acid treatment. Additionally, the variability in material removal makes it difficult to achieve uniform surface quality. Addressing these pain points requires a robust solution like an online acid density meter to ensure precision and process stability.

Benefits of Introducing Inline Acid Density Meter

Transforming Efficiency and Precision in Acid Pickling

The introducing of an inline acid density meter, such as Lonnmeter’s advanced solution, revolutionizes the steel pickling process by providing real-time acid density measurement online. This technology ensures acid concentrations are maintained within optimal ranges, preventing over-pickling that can cause hydrogen embrittlement or under-pickling that leaves oxide scale intact. By monitoring density shifts caused by metal ion accumulation, the meter triggers automated adjustments.

Cost Savings and Operational Reliability

Implementing an acid density meter inline delivers substantial cost benefits, cutting energy consumption. By integrating with PLC/DCS systems via 4-20 mA or RS485 outputs, the meter automates acid replenishment and waste management.

Environmental Compliance and Versatility

The acid density meter online supports environmental compliance by maintaining acid mist levels below EPA limits, avoiding fines and simplifying waste acid treatment. Its versatility extends to batch processes, where it assesses acid depletion post-cycle, and waste treatment systems.

Enhanced Process Control and Future-Readiness

Beyond immediate gains, the inline acid density meter enables predictive process control by detecting trends in density data, allowing technicians to anticipate acid degradation or equipment issues before they escalate. Integrated with automation, it reduces manual intervention, freeing staff to focus on strategic tasks. For forward-thinking steel pickling factories, this technology supports custom OEM/ODM upgrades and R&D collaboration, ensuring access to cutting-edge innovations.

FAQs

How does the inline acid density meter enhance the pickling process?

The acid density meter inline provides real-time acid pickling process data, maintaining optimal concentration, improving efficiency and ensuring ASTM-compliant steel finishes.

Can it withstand harsh pickling environments?

Yes, the inline acid density meter’s acid-resistant Hastelloy sensors and long lifespan make it ideal for corrosive pickling process metal conditions, outlasting traditional glass or plastic tools.

Is integration with existing systems possible?

Absolutely, the acid density meter online supports 4-20 mA and Modbus protocols, integrating with PLC/DCS for automated steel pickling process control, reducing manual intervention.

Elevating the pickling process in steel demands precise acid density measurement online to optimize quality, reduce waste, and lower costs. Lonnmeter’s inline acid density meter delivers unparalleled accuracy, durability, and automation. Act now—claim one of 1,000 free samples (first come, first served) or download our free acid pickling process pdf to unlock insights. Submit your inquiry for custom OEM/ODM solutions (e.g., WiFi connection, mobile app) or join our R&D program for early tech access. Transform your pickling metal process today!

Post time: Jun-10-2025