The Benfield Process is a cornerstone of industrial gas purification, widely adopted in chemical plants to remove carbon dioxide (CO2) and hydrogen sulfide (H2S) from gas streams, ensuring high-purity outputs for applications in ammonia synthesis, hydrogen production, and natural gas processing. Precise control over the concentration of this scrubbing solution is critical to prevent operational challenges such as foaming, reduced absorption efficiency, or equipment corrosion. Inline potassium carbonate concentration meters and inline potassium carbonate concentration analyzers offer a transformative solution by providing continuous, real-time monitoring of K2CO3 and potassium bicarbonate (KHCO3) levels, enabling operators to optimize the gas purification process and achieve significant cost savings.

This comprehensive guide explores the mechanics of the Benfield Process for acid gas removal, and their benefits for industries like ammonia production plants, hydrogen production plants, natural gas processing plants, petrochemical plants, direct iron ore reduction plants, and coal gasification plants. By integrating these advanced tools, plant operators can enhance efficiency, ensure compliance with stringent regulations, and deliver consistent, high-quality gas outputs.

The Chemistry and Mechanics of the Benfield Process

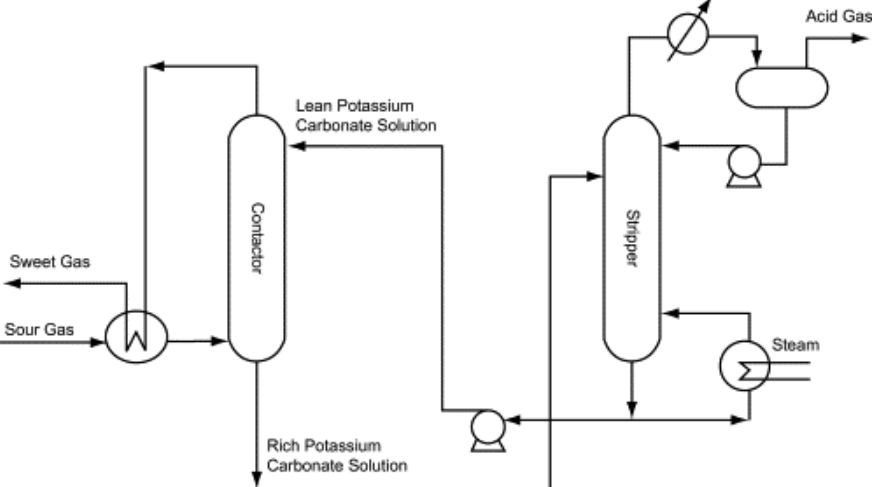

The Benfield Process, developed by the U.S. Bureau of Mines and licensed by UOP (now part of Honeywell), is a thermally regenerated, cyclical solvent process that uses a hot K2CO3 solution to remove CO2 and H2S from gas streams. It is a trusted method for gas purification in industries requiring high-purity gases, such as ammonia synthesis for fertilizers, hydrogen production for refining, and natural gas processing for pipeline specifications. The process operates through two primary stages: absorption and regeneration.

During the absorption phase, the gas stream is introduced at the bottom of an absorber column, flowing counter-current to a hot K2CO3 solution (typically 20–30 wt%) at temperatures between 100°C and 110°C and high pressures.

H2S is also absorbed, forming other reaction products. The purified gas exits the top of the absorber, while the rich solution, laden with KHCO3, is transferred to a regenerator (stripper). In the regeneration phase, the solution is heated with steam or subjected to pressure reduction, reversing the reaction to release CO2 and H2S, thereby regenerating the K2CO3 solution for reuse. This cyclical process ensures continuous operation, but its efficiency hinges on maintaining optimal K2CO3 and KHCO3 concentrations to avoid operational issues.

Why Concentration Control is Critical

Precise control of the K2CO3 solution’s concentration is essential for several reasons. Excessive KHCO3 levels can lead to foaming in the absorber, which disrupts gas-liquid contact, reduces CO2 absorption efficiency, and risks equipment damage. Conversely, insufficient K2CO3 concentrations diminish the solution’s capacity to absorb acid gases, resulting in incomplete purification and non-compliance with product specifications. Additionally, improper concentrations can increase energy consumption during regeneration, as overly rich solutions require more steam to release captured gases, and can exacerbate corrosion in equipment due to the alkaline nature of the solution.

Historically, concentration monitoring relied on manual sampling and laboratory analysis, a process that is labor-intensive, prone to delays, and unable to provide real-time insights. These limitations can lead to process inefficiencies, increased operational costs, and potential regulatory violations. Inline potassium carbonate concentration meters address these challenges by delivering continuous, accurate measurements, enabling immediate adjustments to maintain optimal process conditions and enhance the performance of the Benfield Process Scrubber.

How Inline Concentration Meters Function

Inline potassium carbonate concentration meters or analyzers are advanced inline process monitor designed to measure K2CO3 and KHCO3 concentrations directly within the process stream, eliminating the need for manual sampling. These devices are engineered to operate under the harsh conditions of the Benfield Process, including high temperatures (up to 110°C) and pressures, and are constructed with corrosion-resistant materials to withstand the alkaline environment of the scrubbing solution.

Several technologies are employed in these meters, each offering unique advantages:

Ultrasonic Measurement: These meters measure the speed of sound through the liquid, which correlates with its density and concentration. This method is unaffected by the solution’s conductivity, color, or transparency, making it highly reliable for the Benfield Process for CO2 removal. With measurement accuracies of 0.05% to 0.1%, ultrasonic concentration meters provide precise data for maintaining optimal alkali-to-bicarbonate ratios.

Conductivity Measurement: These meters assess the electrical conductivity of the solution, which varies with the concentration of K+ and HCO3- ions. Conductivity meters are cost-effective and suitable for monitoring ionic changes but may require temperature compensation to ensure accuracy.

Density Measurement: By measuring the solution’s density, which shifts with the proportion of K2CO3 and KHCO3, these meters provide a reliable indicator of concentration. Density meters are accurate but may need calibration for temperature variations.

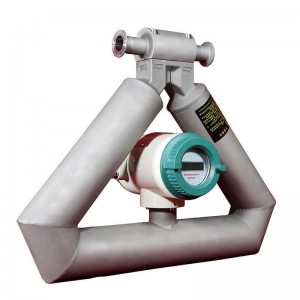

Coriolis Measurement: While primarily used for flow measurement, Coriolis meters can also measure density with high accuracy (e.g., ±0.001g/cc), offering a drift-free method to infer concentration in two-component mixtures like K2CO3 and KHCO3 solutions.

These meters are typically installed in the pipeline between the absorber and regenerator or in the recirculation line, ensuring comprehensive monitoring of the gas purification system. By providing real-time data, they enable operators to detect and correct concentration deviations instantly, preventing issues like foaming or insufficient absorption.

Installation and Integration Strategies

To maximize the effectiveness of inline potassium carbonate concentration analyzers, strategic installation is key. Meters should be placed at critical points, such as the pipeline from the absorber to the regenerator and the lean solution recirculation line, to capture concentration changes throughout the process. Redundant systems can be deployed to ensure continuous operation during maintenance, minimizing downtime.

Integration with plant control systems allows for automated adjustments, such as regulating K2CO3 dosing or steam input, based on real-time data. Regular calibration with standard solutions is essential to maintain accuracy, particularly in the dynamic conditions of the Benfield CO2 removal process.

|

Technology |

Advantages |

Applications in Benfield Process |

|

Ultrasonic |

High accuracy, unaffected by conductivity |

Monitoring K2CO3/KHCO3 in absorber pipelines |

|

Conductivity |

Cost-effective, simple to implement |

Tracking ionic changes in scrubbing solution |

|

Density |

Reliable for concentration inference |

Measuring solution density in regenerator |

|

Coriolis |

Drift-free, high precision |

Comprehensive monitoring in high-flow systems |

This table outlines the key technologies used in concentration meters, highlighting their suitability for the Benfield Process.

Benefits of Inline Concentration Meters

Enhancing Operational Efficiency

The adoption of inline potassium carbonate concentration meters significantly improves operational efficiency in chemical plants. By providing continuous, real-time data, these meters enable operators to detect and correct concentration deviations instantly, reducing the risk of process disruptions. For instance, preventing foaming caused by high KHCO3 levels minimizes energy consumption in the regenerator, as less steam is required to release captured gases. Optimizing K2CO3 dosing also reduces raw material waste, lowering operational costs.

In ammonia production plants, precise concentration control ensures consistent synthesis gas quality, reducing energy costs associated with rework. In natural gas processing plants, maintaining optimal K2CO3 levels ensures compliance with pipeline specifications, avoiding costly penalties. Industry estimates suggest that plants using inline meters can achieve energy savings of up to 15% and reduce labor time by automating monitoring processes, eliminating the need for manual sampling.

Ensuring Product Quality and Compliance

The Benfield Process is critical for producing gases that meet stringent purity standards, such as low CO2 and H2S levels for ammonia synthesis or natural gas pipelines. Inline concentration meters ensure that the scrubbing solution maintains the correct composition, resulting in high-quality purified gas. For example, in hydrogen production plants, precise control supports hydrogen purity for refining processes, while in petrochemical plants, it enables the production of high-purity chemicals like ethylene oxide.

With increasing environmental regulations, compliance is a priority. Inline meters help plants demonstrate adherence to emission standards by maintaining efficient CO2 removal, reducing the risk of fines or operational disruptions. This is particularly critical in coal gasification plants, where syngas purity is essential for downstream applications, and in direct iron ore reduction plants, where gas quality impacts production efficiency.

Cost Savings and Long-Term Value

The financial benefits of inline potassium carbonate concentration analyzers are substantial. By automating concentration monitoring, these devices reduce labor costs associated with manual sampling, which can save up to an hour per day in large-scale operations. They also minimize waste by preventing over- or under-dosing of K2CO3, optimizing raw material usage. Additionally, by reducing energy consumption in the regeneration phase, plants can achieve significant cost savings, particularly in energy-intensive industries like natural gas processing and ammonia production.

The long-term value is further enhanced by the durability of these meters, which are designed with corrosion-resistant materials to withstand the alkaline environment of the gas purification process. Their low maintenance requirements and ability to integrate with existing control systems make them a cost-effective investment for chemical plants seeking to optimize their Benfield Process for acid gas removal.

Choosing the Right Inline Concentration Meter

Key Selection Criteria

Selecting the appropriate inline potassium carbonate concentration meter requires careful consideration of several factors to ensure alignment with the operational needs of chemical plants:

- Accuracy and Reliability: The meter must provide precise measurements (e.g., 0.05%–0.1% accuracy) under the high temperatures and pressures of the Benfield Process to ensure consistent performance.

- Temperature and Pressure Resistance: It must withstand operating conditions up to 110°C and high pressures, with robust construction to handle the alkaline solution.

- Material Compatibility: Sensors should be made from corrosion-resistant materials, such as specialized alloys, to ensure longevity in the harsh chemical environment.

- Ease of Installation and Maintenance: The system should integrate seamlessly into existing pipelines and require minimal maintenance to reduce downtime.

- Data Integration: Compatibility with plant control systems is essential for real-time data logging and automated adjustments, enhancing process control.

These criteria ensure that the chosen meter meets the specific requirements of ammonia production plants, hydrogen production plants, natural gas processing plants, petrochemical plants, direct iron ore reduction plants, and coal gasification plants.

Available Technologies and Considerations

Several types of concentration meters are suitable for the Benfield Process, each with distinct advantages. Lonnmeter ultrasonic meters offer high accuracy and are unaffected by solution properties, making them ideal for complex mixtures. Conductivity meters are cost-effective but may require temperature compensation. Density meters provide reliable concentration data but need calibration for temperature variations. Coriolis meters, while more expensive, offer drift-free measurements and are suitable for high-flow systems.

Plant operators should evaluate these technologies based on specific process conditions, such as the expected concentration range (e.g., 20–30 wt% K2CO3), temperature, and budget constraints. For high-purity applications, such as in petrochemical plants, ultrasonic or Coriolis meters may be preferred for their precision.

FAQs

How Do Inline Concentration Meters Enhance the Benfield Process?

Inline potassium carbonate concentration meters provide real-time monitoring of K2CO3 and KHCO3 levels, ensuring the scrubbing solution maintains optimal composition for efficient gas purification. By preventing issues like foaming or insufficient absorption, they enhance the performance of the Benfield Process Scrubber, delivering high-quality gas outputs for applications in ammonia production and natural gas processing.

What Are the Cost Benefits of Using Inline Concentration Meters?

These concentration meters reduce operational costs by automating monitoring, minimizing labor requirements, and preventing waste from incorrect dosing. They also optimize energy usage in the regeneration phase, offering savings of up to 15% in energy-intensive industries like hydrogen production and coal gasification.

Can Inline Concentration Meters Withstand the Benfield Process Conditions?

Modern inline potassium carbonate concentration analyzers are designed to operate reliably under the high temperatures (up to 110°C) and pressures of the Benfield Process. Constructed with corrosion-resistant materials, they ensure long-term performance in the alkaline environment of the gas purification system.

Conclusion

Inline potassium carbonate concentration meters and analyzers are indispensable for optimizing the Benfield Process, enabling chemical plants to achieve precise control over K2CO3 and KHCO3 concentrations. By providing real-time data, these tools enhance the efficiency of gas purification, prevent operational issues like foaming, and ensure compliance with stringent environmental and quality standards.

For industries such as ammonia production plants, hydrogen production plants, natural gas processing plants, petrochemical plants, direct iron ore reduction plants, and coal gasification plants, adopting these advanced concentration meters is a strategic investment that delivers significant cost savings and operational excellence. Contact lonnmeter today to explore tailored inline potassium carbonate concentration meters and unlock the full potential of your gas purification process.

Post time: Jun-26-2025