As global oil prices surge and the shift toward sustainable energy accelerates, the production and adoption of alternative fuels like ethanol, biodiesel, and butanol have reached unprecedented levels. These biofuels are not only reshaping the energy mix but also creating urgent demands for advanced sensing technologies to ensure precision in fuel blending, quality control, and operational efficiency.

Taking ethanol manufacturers and suppliers as an example, an enormous challenge lies in maintaining fuel consistency, optimizing production costs, and meeting strict regulatory standards.

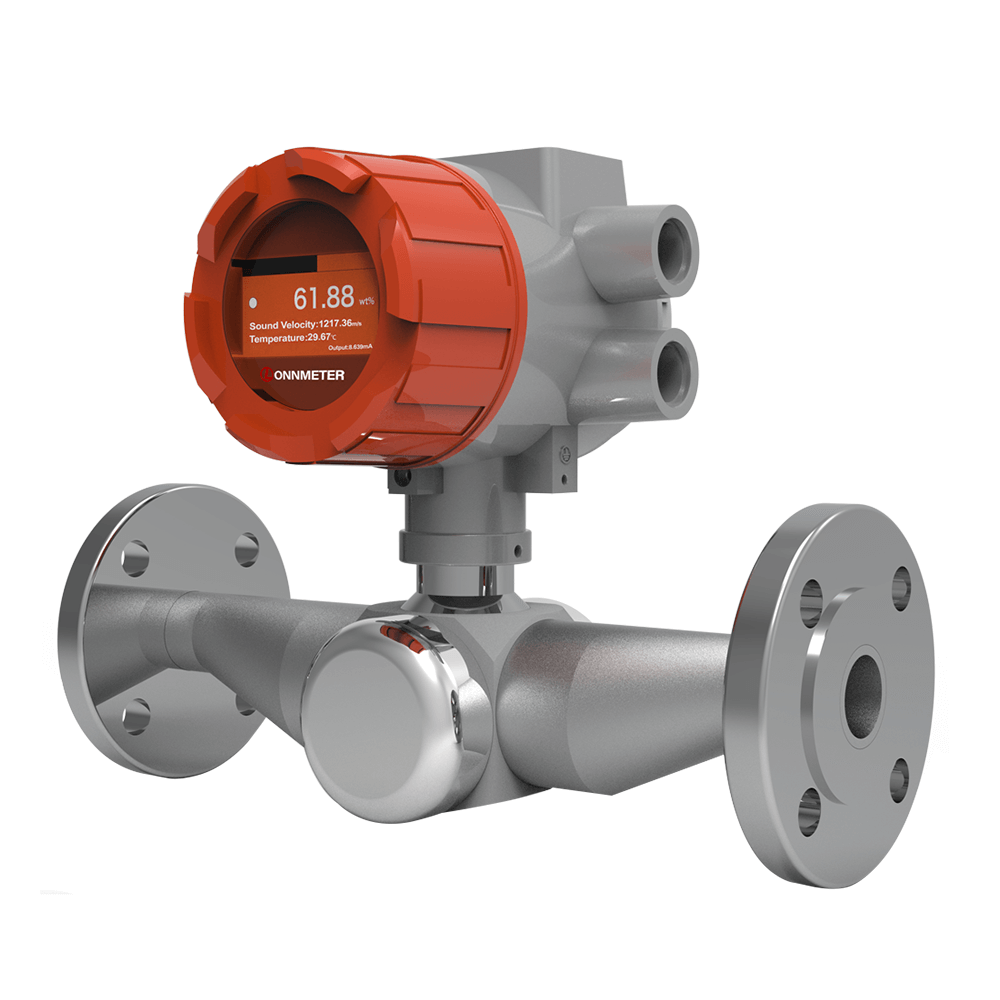

Enter Lonnmeter, a leading innovator in process sensing technology, with a cutting-edge solution designed to address these challenges head-on: the patented inline density meter. Built for the evolving needs of both petrochemical and alternative fuel markets, this breakthrough technology offers a robust, cost-effective way to monitor fuel quality in real time.

Challenges in Traditional Ethanol Manufacturing

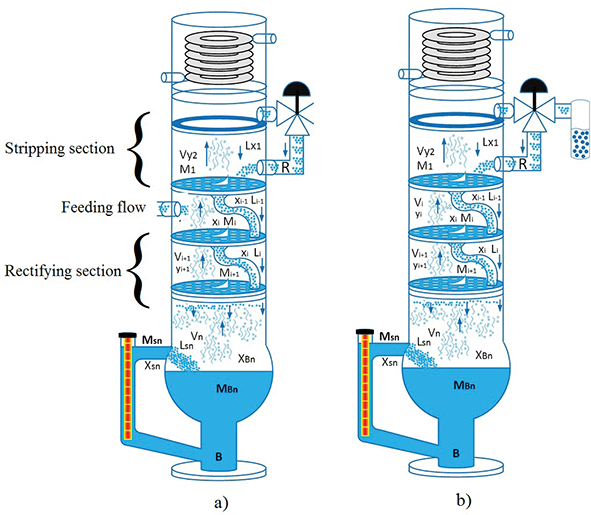

Biofuel manufacturers producing fuel ethanol from corn stover employ traditional distillation in typical, using temperature control to cut ethanol fractions. However, impurities in raw materials like methanol and esters often cause priority vaporization of impurities during distillation. For example, methanol vaporizes at the boiling point 64.7°C before ethanol and mixes into the ethanol fraction.

Temperature control systems cannot effectively distinguish ethanol with methanol and other impurities, leading to significant fluctuations in finished ethanol purity and frequent rework.

Impurity Leading to Purity Errors

When methanol content in raw fermentation liquor is higher than 1.5%), the mixture of ethanol-methanol-water vaporizes prior to pure ethanol while the temperature at the top of the distillation column reaches 78.3 °C. Therefore, density of the ternary mixture is far below than the target value 0.80 g/cm³. Temperature control systems cannot identify this discrepancy and continue normal extraction, resulting in finished products with excessive methanol content.

Postponed Manual Intervention

Manual density sampling and testing take 20-minute delay after sampling. During this period, 5–8 tons of non-conforming ethanol may already have been extracted, and real-time adjustment of the reflux ratio is impossible, leading to poor process stability.

Lonnmeter Solutions for Biofuel Quality Monitoring

High-Precision Real-Time Monitoring

Real-time density measurement by Lonnmeter’s patented technology enables precise analysis of fuel components. The Coriolis mass density meter measures mass density by fluid vibration frequency, achieving a precision of ±0.001 g/cm³. It can distinguish density differences among ethanol, water, methanol, and other components in time, avoiding purity misjudgments caused by methanol vaporization in traditional temperature control.

The tuning fork density meter, with ±0.001 g/cm³ precision, adapts to viscous liquor less than 2000 CP in high-temperature and high-pressure scenarios. Meanwhile, built-in temperature compensation corrects the impacts caused by density fluctuation with temperature, and alarms in advance by monitoring density fluctuation standard deviation (σ), providing reliable data support for process control.

Dynamic Closed-Loop Control

Lonnmeter’s solutions achieve dynamic optimization of process parameters through automated control logic. Preset density thresholds trigger linkage mechanisms. For example, increase reflux ratio automatically when ethanol distillation density is too high or adjusting the extraction volume when density is too low.

Design for Anti-Interference Performance and Reliability

Addressing the rigors of industrial scenarios, Lonnmeter equipment features corrosion-resistant materials and explosion-proof designs. Materials such as Hastelloy and titanium alloy withstand strong corrosive media like methanol and acetic acid, extending equipment life to 8–10 years—2–3 times longer than traditional stainless steel.

Anti-clogging flow channel designs reduce retention risks of high-viscosity fluids. Explosion-proof certifications suit flammable and explosive environments, while a wide temperature range (-40 °C~150 °C) covers extreme conditions from Arctic cold to tropical heat, ensuring stable operation.

Versatile Application

Inline density meters are applicable to the entire fuel production, storage, transportation, and application chain. In bioethanol distillation, real-time monitoring of column top density enables precise cutting of 95% purity ethanol. In petrochemical vacuum distillation, dynamic fraction cutting by density reduces overlap from 15% to below 5%, increasing yield by 8%. In fuel storage and transportation, density data converts volumetric flow to mass flow, avoiding measurement errors caused by temperature and ensuring fair trade settlements. In aviation fuel monitoring, real-time pollution warnings ensure compliance with density standards.

Intelligent Integration and Data Management:

Lonnmeter equipment supports IIoT (Industrial Internet of Things) integration, enabling remote monitoring, data traceability, and predictive maintenance via cloud platforms. Precise control of fuel quality is key to enhancing production efficiency and market competitiveness.

Contact us today to enjoy free customized solutions, where a professional team will design exclusive density monitoring plans based on your process scenarios and fuel types; the first 100 applicants can also receive limited free samples to verify equipment accuracy and performance in real-world tests.

Post time: Jun-06-2025