The production of sodium silicate water glass demands meticulous control over the inline concentration of critical components such as Na2O, K2O, and SiO2 to ensure consistent product quality and operational efficiency. Advanced tools like salt concentration meters, silica sand concentration meters, and concentration meters enable water glass sodium silicate suppliers to monitor and adjust these parameters in real time, minimizing deviations and optimizing costs.

Technical Know-How and Chemical Process

The manufacturing of sodium silicate water glass, a versatile compound integral to industries such as construction, textiles, and mining, requires precision at every stage. The process begins with the fusion of high-purity silica sand (SiO2) and alkali carbonates, such as sodium carbonate (Na2CO3) or potassium carbonate (K2CO3), at temperatures ranging from 1200°C to 1500°C, followed by dissolution in autoclaves and filtration to remove impurities. Even minor fluctuations in Na2O concentration or SiO2 concentration can compromise viscosity, density, or purity, leading to inconsistent product performance.

Why Precision in Concentration Monitoring Is Essential

The production of sodium silicate water glass hinges on maintaining an exact balance of raw materials, as the SiO2 concentration measurement and Na2O concentration directly influence the product’s adhesive properties, viscosity, and chemical stability. During the high-temperature melting phase, where silica sand is fused with alkali carbonates, or the dissolution stage in autoclaves operating at 4–5 bar and 140–150°C, even slight deviations in composition can disrupt the process. Advanced inline concentration meters, often referred to as salt concentration meters or silica sand concentration meters, provide continuous monitoring of these critical components, allowing manufacturers to detect and correct issues instantly, thereby ensuring consistent product quality.

The benefits of precise inline concentration measurement extend beyond quality assurance. By maintaining optimal alkali-to-silica ratios, manufacturers can minimize waste, reduce energy consumption, and ensure compliance with stringent industry regulations.

Risks of Inconsistent and Inaccurate Concentration Measurement

Without robust inline concentration measurement, manufacturers face significant challenges that can undermine their operations. Variations in Na2O concentration can result in products with unreliable performance, such as weak adhesives or inconsistent sealants. Additionally, off-specification batches necessitate costly rework or disposal, increasing production expenses.

Manual sampling, compared with modern inline concentration meters, is time-consuming and prone to errors, leading to process delays and higher labor costs. Furthermore, failure to meet regulatory standards for purity can result in penalties or lost contracts, particularly in high-purity applications like textiles or ceramics. By integrating salt concentration meters and silica sand concentration meters, water glass sodium silicate suppliers can mitigate these risks, ensuring a streamlined and cost-effective production process.

Tools for Effective Inline Concentration Measurement

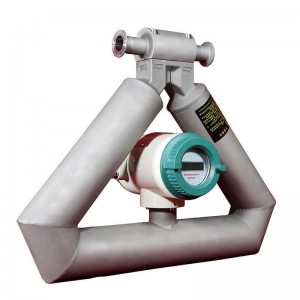

The ultrasonic concentration meter by Lonnmeter is a non-nuclear density meter specifically designed for real-time density and concentration measurement in slurries and other liquids, making it highly suitable for the demanding conditions of water glass production.

Unlike traditional nuclear density meters, this device utilizes safe, non-radiative ultrasonic technology, which measures the transmission time of sound waves from the signal source to the signal receiver to infer the speed of sound and, subsequently, the density and concentration of the liquid.

This method is unaffected by the liquid's conductivity, color, or transparency, ensuring extremely high reliability and accuracy, with users achieving measurement accuracies of 0.05% to 0.1%. This precision is crucial for maintaining the exact alkali-to-silica ratios required in water glass production, ensuring consistent product quality.

Choosing the Right Concentration Meter for Your Needs

Selecting the appropriate concentration meter requires careful consideration of several factors. The specific stage of production, such as melting or autoclave dissolution, determines whether salt concentration meters or silica sand concentration meters are more suitable. Budget constraints also play a role, as general concentration meters offer broader functionality but come with a higher cost. For applications requiring exceptional purity, such as textile processing, high-precision SiO2 concentration measurement is essential, necessitating advanced sensors. Additionally, compatibility with existing process control systems ensures seamless integration and data utilization. By evaluating these factors, water glass sodium silicate suppliers can invest in inline concentration meters that align with their operational goals, enhancing both product quality and efficiency.

Integrating Concentration Meters into the Production Workflow

To fully harness the potential of inline concentration meters, manufacturers should strategically integrate these tools into their production systems. Positioning silica sand concentration meters in the melting tank and salt concentration meters in the autoclave ensures comprehensive monitoring across key stages.

Deploying redundant systems minimizes downtime during maintenance, maintaining continuous operation. By leveraging analytics from these meters, water glass sodium silicate suppliers can optimize raw material ratios, reduce waste, and enhance overall efficiency.

FAQs

How Do Salt Concentration Meters Enhance Water Glass Quality?

Salt concentration meters provide real-time monitoring of Na2O concentration and K2O concentration, ensuring the alkali-to-silica ratio remains consistent. This precision prevents variations in viscosity and density, delivering reliable sodium silicate water glass for applications like adhesives and detergents, enhancing overall product quality.

What Role Do Silica Sand Concentration Meters Play?

Silica sand concentration meters are essential for accurate SiO2 concentration measurement during the melting phase, ensuring silica content aligns with specifications. This maintains clarity and strength in sodium silicate water glass, critical for high-purity applications like textiles and ceramics.

Can Inline Concentration Meters Reduce Production Costs?

By minimizing off-spec batches, optimizing raw material usage, and automating monitoring, inline concentration meters like salt concentration meters and silica sand concentration meters significantly reduce production costs. Water glass sodium silicate suppliers benefit from lower waste and labor expenses, enhancing profitability.

Precise control of Na2O concentration, K2O concentration, and SiO2 concentration is vital for producing high-quality sodium silicate water glass that meets the demands of industries like construction, textiles, and mining.

By adopting these technologies and best practices, manufacturers can streamline operations and deliver superior products. Ready to elevate your water glass production? Contact our team to explore advanced concentration meters tailored to your needs and unlock the full potential of your manufacturing process.

Post time: Jun-26-2025