In the hydrogen fuel cell manufacturing sector, the Membrane Electrode Assembly (MEA) serves as the core component for energy conversion, directly determining the battery’s efficiency and lifespan. The first step for MEA production via heat transfer is catalyst slurry mixing—a critical step influencing final product quality. This process requires precise mixing of Pt-C catalysts, solvents, and binders to form a uniformly dispersed stable mixture.

Traditional mixing struggle to precisely control the proportion of each component and dispersion state, leading to issues such as uneven coating and reduced catalytic activity in subsequent steps. The application of inline density meters offers a breakthrough solution, enabling precise regulation of component ratios and dispersion effects through real-time monitoring of slurry density changes.

Lonnmeter Group, a leading manufacturer and supplier of inline density meters, has dedicated decades to providing professional solutions for clients worldwide. These solutions have helped numerous industrial factories, power plants, and metallurgical enterprises reduce costs and improve efficiency.

The Critical Role of Slurry Mixing

The performance of hydrogen fuel cell MEAs highly depends on the uniformity and stability of catalyst slurries. For example, anode slurries require 15% Pt-C catalyst uniformly dispersed in a mixed solvent of 40% deionized water, 40% methanol, and 5% ionomer solution; cathode slurries demand higher proportions of catalyst (20%) and binder (10%). This precise ratio not only affects the slurry’s physical properties but also directly influences the distribution of catalytic active sites and proton conductivity.

Improper density control may cause catalyst agglomeration or sedimentation, resulting in uneven thickness of the coated catalyst and even overall battery performance. For instance, a higher density may indicate excessive catalyst or solvent evaporation, increasing slurry viscosity and causing "orange peel" or "pinhole" defects during coating; a lower density may indicate insufficient catalyst, failing to provide adequate reaction sites and reducing battery efficiency.

Limitations of Traditional Slurry Density Control

Traditional catalyst slurry mixing relies on manual weighing and offline testing in primary. This approach lags behind real-time process greatly—obtaining test results from sampling often takes 15–30 minutes, by which time the slurry may have entered the next process, leading to substantial rework waste.

Manual operations struggle to detect nanoscale catalyst particle agglomeration. Additionally, factors such as temperature changes and solvent evaporation cause dynamic density fluctuations in slurries, which traditional processes cannot compensate for in real time, further exacerbating quality instability risks.

Working Principle and Technical Advantages

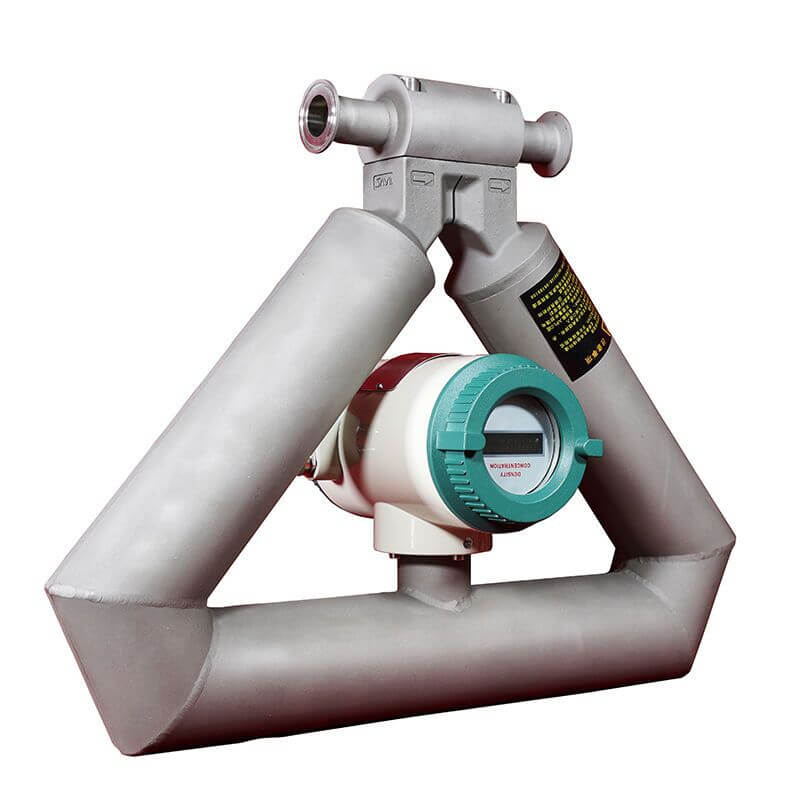

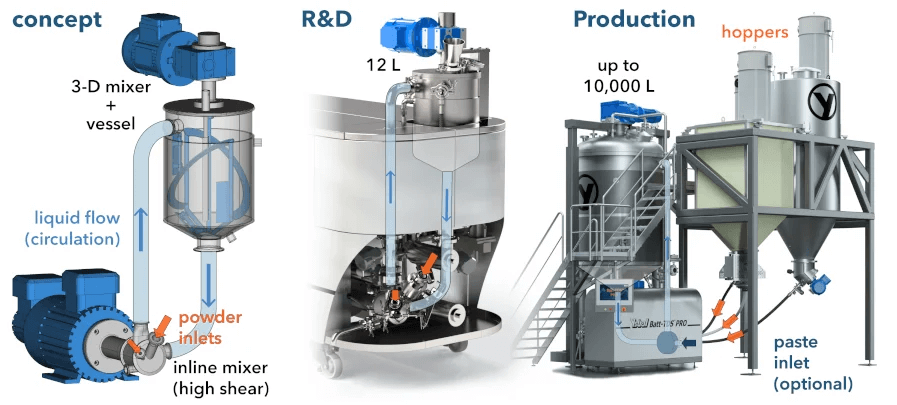

To address these challenges, Lonnmeter engineers developed inline density meters based on the Coriolis force principle, which measure fluid vibration frequency to obtain real-time density data with precision up to ±0.001 g/cm³. In slurry mixing of hydrogen fuel cell, these high-precision monitoring devices can be installed at the outlet of mixing tanks or circulation pipelines to continuously collect density and temperature data, with compensation algorithms eliminating the impact of temperature on density.

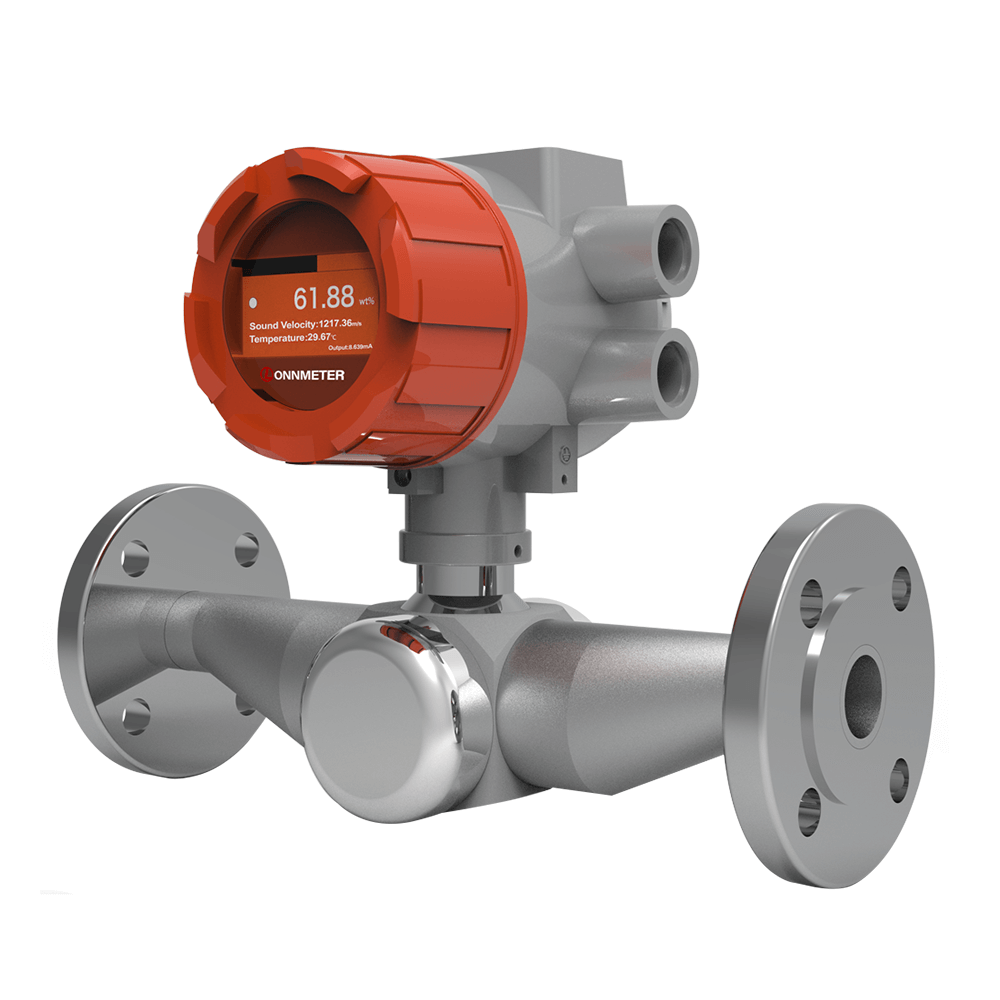

Beyond Coriolis density meters, Lonnmeter has also developed other inline density meters such as tuning fork density meters and ultrasonic density meters to provide intelligent density monitoring sensors for different working conditions. When detecting that the cathode slurry density exceeds the target value, the system automatically calculates the deviation and adds an appropriate amount of solvent through a metering pump; if the density is too low, pre-dispersed catalyst mother liquor is added. This dynamic loop control not only corrects formula deviations but also predicts potential issues through historic data analysis. When density fluctuations exceed thresholds, the system triggers alarms to prompt potential non-uniform dispersion or phase separation, avoiding batch quality accidents further.

Results of Continuous Density Monitoring

Enhanced Fuel Cell Stability

Lonnmeter inline density meters have helped fuel cell manufacturers achieve significant breakthroughs in catalyst slurry mixing. Through real-time monitoring and intelligent regulation, slurry density fluctuation ranges have been drastically reduced from ±0.03 g/cm³ to ±0.001 g/cm³. This improvement directly enhances product consistency and performance stability, increasing the fuel cell power density of one enterprise by 15%.

Significantly Improved Production Efficiency

The time of single-batch production has been shortened, with annual savings exceeding $300,000 in material and rework costs. Furthermore, the application of inline density meters has optimized the entire process. Integrated with DCS systems, they enable fully digitalized management from formula management to quality traceability, laying a foundation for large-scale hydrogen fuel cell production.

Profound Significance for the Hydrogen Energy Industry

As a core carrier of clean energy, hydrogen fuel cells face dual challenges of improving performance and reducing costs. The application of inline density meter technology not only solves key process problems in MEA production but also drives technological upgrading across the entire chain of hydrogen energy industry.

If you are seeking inline process sensors to reduce costs and increase efficiency in automated production, Lonnmeter intelligent instrumentation is one of your ideal choices. The company is offering 100 free samples worldwide—quantities are limited, so act fast! Contact us to obtain a free customized solution and apply for free samples.

Post time: Jun-06-2025