Inline density meters are required for real-time chemical reaction monitoring in linalyl acetate synthesis. Precise density readings (target: 0.890–0.894 g/cm³) enable automated esterification reaction control with density meters. Continuous data ensures acetyl chloride feed rate monitoring, preventing overdosing, which leads to excessive hydrogen chloride and off-odor in perfume products.

Direct inline measurement eliminates lag between production and laboratory analysis, supporting immediate process correction and anomaly detection. Integration of 4-20mA signal and RS485 communication allows stable, interference-resistant real-time data transmission even in aggressive, anhydrous organic solvent environments. Inline control boosts raw material conversion by over 30%, reducing acetyl chloride and linalool waste.

Reliable density monitoring sharpens product compliance to GB 29985-2013 purity standards. Corrosion-resistant density meters with Hastelloy bodies and PTFE lining maintain accuracy under acetyl chloride exposure, ensuring equipment integrity. These instruments are essential for continuous process monitoring, preventing batch variability, and maintaining perfumery quality at scale.

Linalyl Acetate

*

Inline Density Measurement in Linalyl Acetate Synthesis

Inline density measurement is critical for chemical reaction monitoring in linalyl acetate synthesis, where density variation directly impacts esterification reaction control. Continuous real-time monitoring stabilizes feed ratios of linalool and acetyl chloride, optimizing raw material conversion and reducing solvent waste. Automated prevention of acetyl chloride overdosage using inline density meters minimizes excess HCl formation, ensuring stable chloride hydrogen odor control in perfume products.

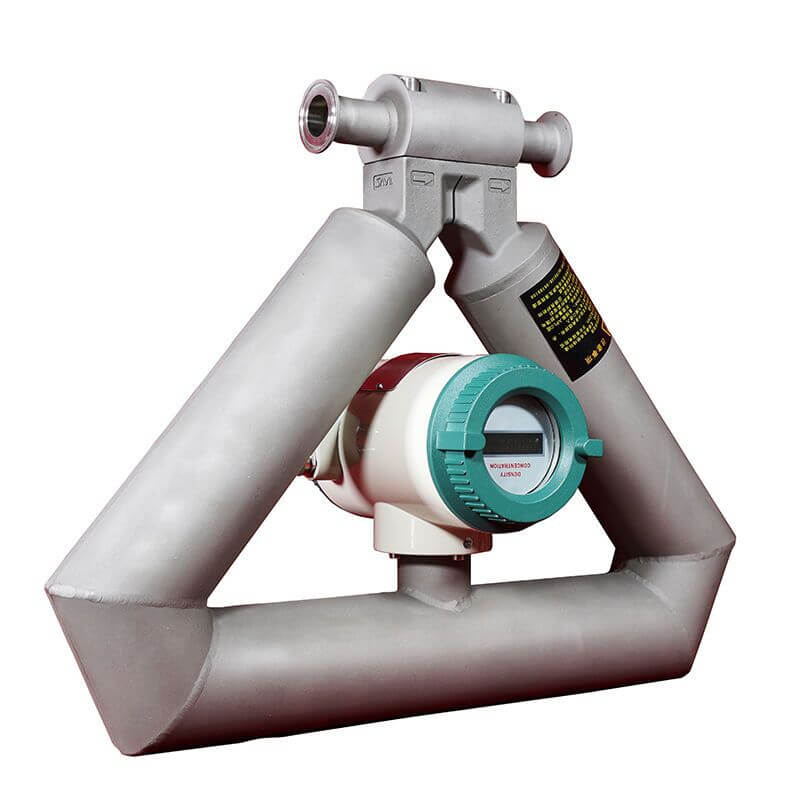

Tuning fork density meters with Hastelloy bodies and PTFE lining withstand anhydrous organic solvents and resist acetyl chloride corrosion, maintaining signal reliability for process control. Integrated RS485 communication and 4-20mA signal output support seamless data transfer to production PLCs, enabling immediate anomaly detection and reaction automation. This precision in process control guarantees compliance with quality standards for linalyl acetate (GB 29985-2013) and increases production efficiency by up to 30%.

Overview of Esterification of Linalool

Continuous esterification of linalool with acetyl chloride in anhydrous organic solvents produces linalyl acetate, a core perfume component. The process requires precise acetyl chloride feed rate monitoring to control reactant stoichiometry and limit chloride hydrogen odor in perfume products. Inline density meters—configured for 0.890–0.894 g/cm³ at the distillation end—provide real-time chemical reaction monitoring, supporting automated process control and quality standards for linalyl acetate (GB 29985-2013).

Product from the reactor enters a distillation section, where Lonnmeter corrosion-resistant density meters with Hastelloy and PTFE lining ensure measurement integrity in aggressive acetyl chloride atmospheres. When the density indicates pure linalyl acetate, automated valve systems direct output toward collection, separating it from lower-density unreacted mixtures. These mixtures are automatically recycled via valve control to improve raw material conversion and reduce waste, enhancing production efficiency by over 30%.

Integrated RS485 communication and 4-20mA signal outputs deliver continuous process monitoring and anomaly detection, supporting rapid corrective actions and minimizing deviations in product quality. The seamless integration of inline density meters optimizes solvent usage and maintains anhydrous conditions essential for esterification reaction control.

Linalool and linalyl acetate synthesis

*

Challenges in Inline Density Measurement

Density drift plagues multiphase esterification, causing linalyl acetate purity to drop below the GB 29985-2013 standard. Localized mixing, temperature shifts, and reagent feed fluctuations skew density readings, undermining esterification reaction control with density meters. Acetyl chloride rapidly attacks sensor wetted surfaces, especially stainless steel, resulting in premature failure. Only Hastelloy bodies with PTFE lining ensure corrosion-resistant density meters for chemical processing under continuous acetyl chloride exposure.

Traditional batch sampling cannot deliver real-time chemical reaction monitoring in linalyl acetate synthesis. Delayed anomaly detection leads to acetyl chloride overdosage and elevated hydrogen chloride levels, triggering odor deviations. Inadequate phase separation at distillation causes unreacted feedstock to contaminate the product, impeding acetyl chloride feed rate monitoring and reducing raw material conversion.

Aggressive solvent systems disrupt RS485 communication in industrial density meters and compromise stable 4-20mA signal integration for process control. Persistent signal instability hinders continuous process monitoring and anomaly detection, limiting production efficiency gains and obstructing compliance with linalyl acetate quality standards.

Benefits of Integrating Inline Density Meters

Real-time density control automates valve actuation at separation stages, boosting linalyl acetate yield by more than 30% compared to batch-based methods. Inline meters immediately flag acetyl chloride overdosage, preventing excessive HCl formation and maintaining precise chloride hydrogen odor control in perfume products. Cylindrical density meters with Hastelloy bodies and PTFE lining resist acetyl chloride corrosion, supporting long-term chemical reaction monitoring in linalyl acetate synthesis. Integrated RS485 and 4-20mA signals deliver stable, accurate process data to central PLC or DCS systems under aggressive chemical conditions. Continuous inline feedback maximizes conversion of feed linalool and acetyl chloride, reducing raw material waste in ester production and consistently enhancing output purity above 95%. Automated, traceable density monitoring supports compliance with GB 29985-2013 quality standards for linalyl acetate, even in processes using anhydrous organic solvents.

Request a Lonnmeter inline density meter quote to address esterification reaction control with density meters in linalyl acetate synthesis. Ensure acetyl chloride feed rate monitoring to prevent acetyl chloride overdosage and unwanted chloride hydrogen odor in perfume products.

Post time: Feb-02-2026