Fluctuations in monomer-to-polymer ratios during the methyl methacrylate production process directly affect molecular weight control, optical clarity, and mechanical performance. Immediate process feedback allows precise dosing in each step of the methyl methacrylate manufacturing process, minimizing costly batch failures. Continuous inline measurements in the methyl methacrylate process flow diagram give operators constant visibility, supporting stable radical polymerization, especially during high exotherm and viscosity shifts.

Accurate monitoring reduces raw material waste by 10%–12%, according to recent industry trials, directly supporting yield optimization. Real-time inline density data maximizes resource efficiency and helps avoid unplanned downtimes linked to undetected deviations or polymerization failures.

MMA Acrylic Sheet Production

*

Introduction

In the methyl methacrylate production process, precise monitoring of monomer purity and reactivity is essential for consistent polymerization. Bulk polymerization methods in acrylic production require tight control of radical initiator dosing and heat removal.

Acrylic sheet polymerization processes rely on real-time readings for dosing, mixing, and casting to prevent defects and off-spec materials. Accurate density control yield superior clarity and uniformity in acrylic sheet production.

Key Industrial Process Overview

The methyl methacrylate production process employs catalytic methylation or direct oxidative esterification to create MMA monomer. Catalytic methylation typically uses mixed Mg/Ga oxide catalysts, achieving high selectivity and yield, while reducing byproduct formation. Direct methylation, modeled in Aspen Plus, enables efficient recycling, allowing MMA purity up to 99.9% with reduced energy use.

The methyl methacrylate process flow diagram covers raw material input, MMA purification steps, and stabilization stages. Stabilized MMA is then delivered to bulk polymerization units via closed piping, minimizing contamination and loss.

The methyl methacrylate bulk polymerization process involves radical initiators, precise heat management, and continuous polymer chain propagation. Reactor thermal control ensures uniform conversion and prevents runaway exothermic reactions.

Acrylic sheet manufacturing process control depends on exact dosing, high-shear mixing, and scaled casting. Acrylic sheet processing techniques such as controlled cooling and bubble management are crucial for consistent clarity and homogeneity. Each step demands tight inline monitoring for stable product quality.

Polymerization of methyl methacrylate to form PMMA plastic

*

Real-time Density Measurement Challenges in Acrylic Sheet Manufacturing

Inline density and concentration measurement in the acrylic sheet manufacturing process faces persistent challenges from process dynamics and material variability. High temperatures in reactive exothermic zones accelerate sensor fouling, causing drift and calibration loss. The methyl methacrylate bulk polymerization process presents rapid viscosity fluctuations, disrupting density meter stability and requiring frequent recalibration.

Suspended resin particles and phase separation during the acrylic sheet polymerization process directly reduce inline sensor accuracy, as instrument response suffers from scattering and uneven flow. Zones within the process may contain variable bubble content or microgel formation, distorting density and concentration data due to transient heterogeneity.

Inline meters must reliably collect accurate measurements and withstand complete cycles of the methyl methacrylate process flow diagram, including MMA purification, stabilization, and bulk polymerization method in acrylic production. Advanced sensor materials and designs are needed to limit downtime and enhance measurement accuracy throughout every step in acrylic sheet manufacturing.

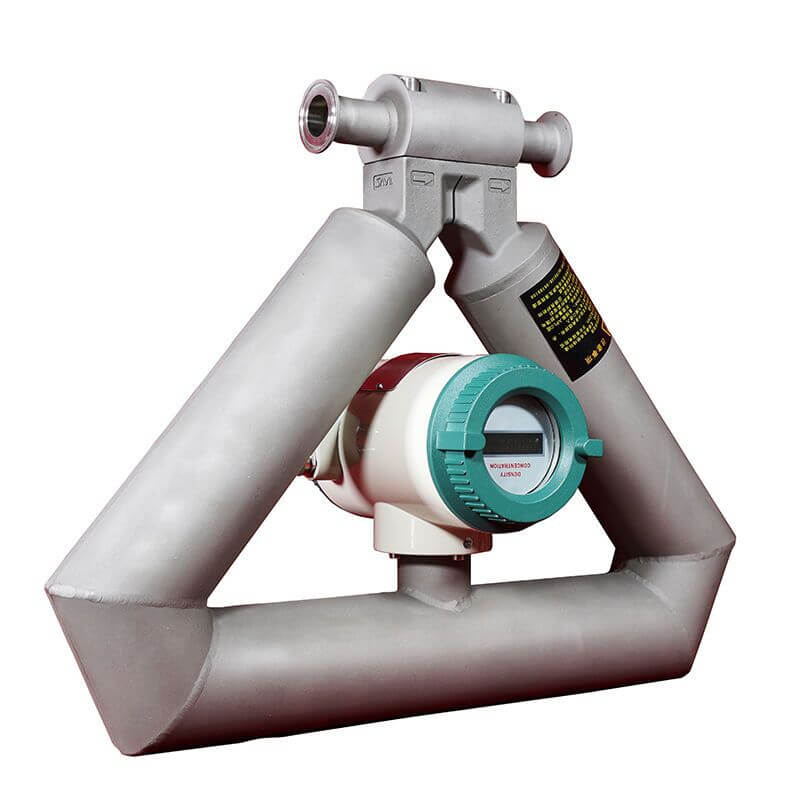

Benefits of Lonnmeter Inline Density Meters

Lonnmeter inline density and concentration meters deliver precise, non-invasive measurements throughout each phase of the acrylic sheet production process, including the methyl methacrylate bulk polymerization process. Sensor response times under 0.5 seconds enable direct process control, supporting precise dosing and casting during the acrylic sheet polymerization process.

Robust instrument design resists sensor drift caused by high temperatures, suspended resin particles, variable bubble content, and microgel formation. Lonnmeter devices maintain ±0.003 g/cm³ accuracy through shifting temperature zones and heterogeneous phases.

Minimize off-spec batches and resource waste. Specify instruments for direct integration into the methyl methacrylate process flow diagram and bulk polymerization method in acrylic production. Contact Lonnmeter sales engineer right now.

Post time: Jan-26-2026