During malonic acid synthesis, density threshold monitoring reveals when conversion to diethyl malonate or monoethyl malonate has reached its endpoint. Continuous measurement supports direct process adjustments, preventing batch inconsistencies and reducing raw material waste.

Inline density measurement delivers real-time, continuous tracking of esterification reaction progress, eliminating manual sampling and endpoint ambiguities. Inline density measurement in chemical reactions allows swift, automated control adjustments, reducing energy consumption and waste. Industrial studies prove that integration of inline density meter for chemical processes raises output consistency by over 95%, according to recent process research. This optimization drives energy efficiency in chemical manufacturing while supporting strict quality requirements for diethyl malonate synthesis and monoethyl malonate synthesis.

Diethyl Malonate Plant

*

Overview of Esterification Process Flow

Malonic acid reacts with anhydrous ethanol under precise temperature control, producing diethyl malonate and monoethyl malonate via esterification. Each stage shows distinct density changes—density of reactant solution decreases as conversion progresses. Inline density measurement in chemical reactions provides continuous tracking of these shifts. Real-time detection of the density threshold marks the endpoint of reaction in chemistry.

Process enhancements, achieved via inline density threshold monitoring, minimize overprocessing and raw material usage. Continuous inline measurement maximizes product yield and ensures energy efficiency in chemical manufacturing. This supports high-throughput diethyl malonate synthesis and monoethyl malonate applications, leveraging malonic acid chemical properties with precise process control.

Challenges in Inline Density/Concentration Measurement

Reaction mixtures in esterification fluctuate in viscosity and density due to varying malonic acid conversion rates. Inline density meter calibration requires strict temperature compensation, as each 1°C shift can alter solution density by approximately 0.15–0.2 kg/m³, complicating reaction endpoint detection.

By-product presence reduces endpoint measurement sensitivity, impacting density threshold monitoring accuracy. Manual sampling in diethyl malonate synthesis introduces errors up to 3%, with delays that hinder immediate reaction completion signaling and real-time process corrections.

Diethyl malonate

*

Benefits of Integrating Inline Density Meters

Inline density meter calibration ensures consistent, real-time reaction endpoint detection during malonic acid and diethyl malonate synthesis. Using inline density meter for chemical processes reduces off-spec batches, providing continuous monitoring of chemical conversion in esterification using malonic acid and anhydrous ethanol. Automated process adjustments maintain the correct endpoint of reaction in chemistry, minimizing deviations from desired product stoichiometry.

Density threshold monitoring enables rapid identification of reaction completion indicators, reducing delays linked to manual sampling. Inline density measurement in chemical reactions directly cuts overprocessing. This minimizes excess raw material and cuts yield losses, as shown in monoethyl malonate synthesis, where density tracking reduces waste by over 10%. Optimized endpoint control reduces energy consumption by 8–12% during diethyl malonate applications through precise heating and cooling cycles.

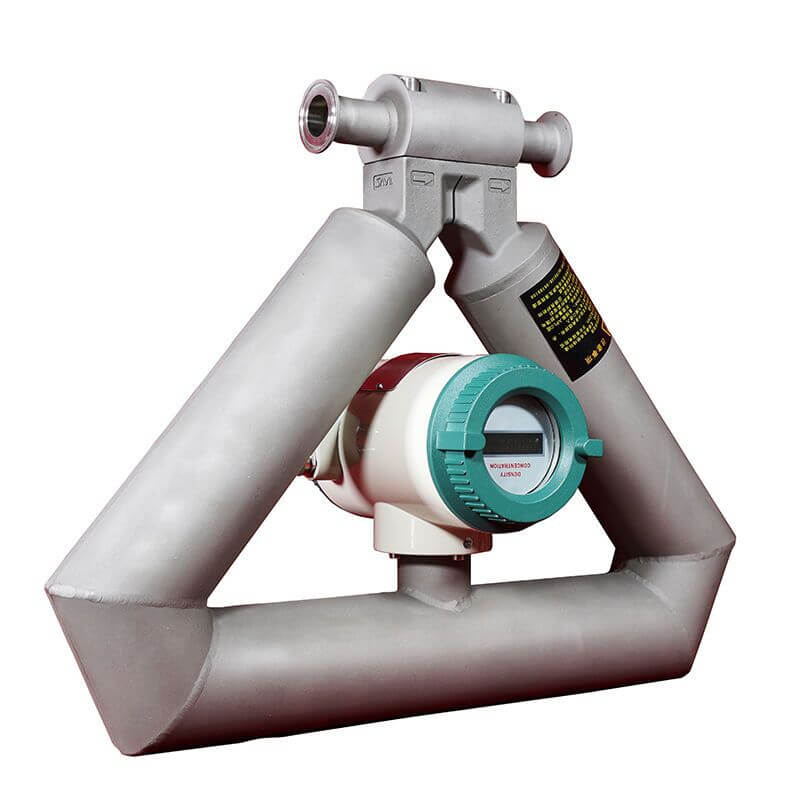

Value of Lonnmeter Inline Density/Concentration Meters

Lonnmeter inline density meters deliver ±0.001 g/cm³ accuracy, critical for reliable reaction endpoint detection in esterification. High-precision, real-time density measurement supports malonic acid transformation to diethyl malonate and monoethyl malonate, covering key benchmarks in diethyl malonate synthesis and monoethyl malonate synthesis.

Units designed for anhydrous ethanol in industry remain stable under corrosive, high-throughput conditions. Rugged stainless steel flow cells ensure durability; sensor wetted parts are chemically resistant for malonic acid uses in synthesis and anhydrous ethanol uses.

Request a quote for Lonnmeter inline density meters for chemical reactions requiring strict density threshold monitoring. Achieve precise reaction endpoint detection for malonic acid, diethyl malonate, and monoethyl malonate synthesis using advanced inline instruments only—no software or control systems included.

Post time: Jan-27-2026