The operational and financial performance of oil and gas enterprises is inextricably linked to the precise management of fluid properties, with viscosity being a critical, yet often underappreciated, parameter. Viscosity, a fluid's intrinsic resistance to flow, acts as a primary lever for controlling everything from the efficiency of drilling operations to the quality of end-products. This report presents a central thesis: the traditional approach to viscosity monitoring, which relies on reactive, off-line laboratory analysis, is fundamentally insufficient. Instead, an investment in high-accuracy inline viscometry is a strategic capital expenditure that transitions operations from a reactive posture to a proactive and predictive control model.

1.1 The Viscosity-Value Nexus

The business case for enhancing viscosity measurement accuracy is compelling and multifold. High-precision systems do not merely provide better data; they unlock significant operational efficiencies and deliver substantial financial returns. The analysis indicates a rapid average payback period of approximately nine months for such systems, driven by a combination of factors. Key financial benefits include documented reductions in fuel costs of 1.5% to 2.5%, substantial material savings, and a significant decrease in labor requirements by automating tasks and minimizing manual intervention.

1.2 Key Findings at a Glance

-

Financial Impact: High-accuracy systems justify their investment with rapid returns, primarily through tangible savings in material, energy, and labor costs.

-

Operational Benefits: Real-time, continuous monitoring with a stable and reliable signal enables immediate, automated process adjustments, thereby enhancing quality control, minimizing waste, and reducing operational downtime.

-

Technological Shift: The industry is moving beyond simple measurement to a new paradigm where high-accuracy viscometers are integrated into intelligent, multi-sensor systems. These advanced platforms use sophisticated algorithms and sensor fusion to provide predictive analytics and autonomous control, transforming maintenance and operational strategy.

1.3 Recommendations

To capitalize on these opportunities, it is recommended that management and decision-makers strategically allocate capital for next-generation viscometer technology. This should be viewed not as a simple equipment replacement, but as a foundational upgrade to process control systems. Concurrently, R&D engineers should develop a technology integration roadmap that prioritizes systems with inherent robustness and a capacity for data fusion, while establishing standardized measurement protocols to maximize the value of the new infrastructure.

2.0 Introduction: The Critical Role of Viscosity in Oil & Gas Operations

2.1 The Ubiquity of Viscosity

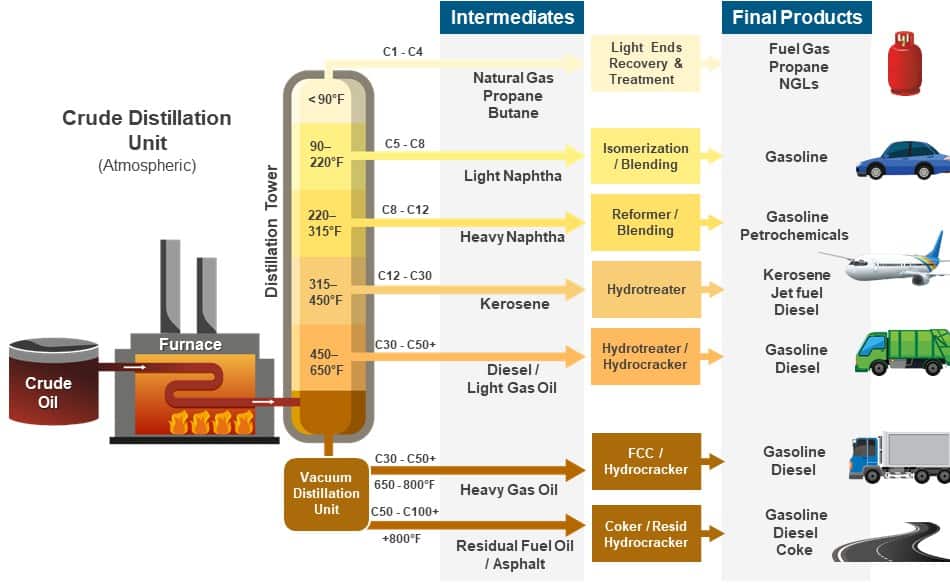

Viscosity is a fundamental physical property defined as a fluid's internal resistance to flow or deformation under applied force. This characteristic is paramount across the entire oil and gas value chain, from the initial stages of extraction to the final refining and transport of end products. In drilling operations, for instance, the viscosity of drilling fluids (or muds) must be meticulously controlled to ensure they can carry rock cuttings to the surface, cool and lubricate the drill bit, and maintain wellbore stability. In pipeline transportation, the high viscosity of heavy crude oil is a major challenge that necessitates real-time adjustments to heating or diluent injection to ensure efficient flow and prevent blockages. The refining and end-product sectors rely on viscosity measurements for quality control of lubricants, fuels, and other refined fractions, as discrepancies can lead to significant performance and quality issues. Viscosity is typically quantified as dynamic viscosity,which is a direct measure of internal resistance,or ask kinematic viscosity, which is the ratio of dynamic viscosity to fluid density.

2.2 The Problem Statement

Historically, viscosity has been measured using off-line, laboratory-based methods such as capillary viscometers or bench-top rotational viscometers. While these lab methods are designed for scientific accuracy under controlled conditions, they are inherently slow and labor-intensive.

The delay between sample collection and result analysis creates a fundamental limitation: process adjustments are made reactively, only after a deviation has already occurred. This leads to periods of off-spec production, overprocessing, and increased downtime while awaiting results. Furthermore, the harsh, real-world conditions of a process stream—including high temperatures, pressures, and flow rates—can make lab measurements inaccurate because the fluid's rheological properties are closely tied to its flow conditions. The challenge, therefore, lies in obtaining continuous, reliable, and real-time viscosity data directly from the process stream, a task for which inline viscometers are uniquely suited.

2.3 Report Scope and Objectives

This report serves as an applied study to investigate how the accuracy of inline viscometers directly impacts oil flow monitoring outcomes. It aims to provide a comprehensive analysis for both management and technical audiences, focusing on cost reduction and efficiency improvement. The report is structured to:

-

Systematically review the technology and operational principles of contemporary inline viscometers.

-

Conduct an in-depth analysis of the various sources of measurement error and the cascading effects of inaccuracy.

-

Compare accuracy requirements across different industrial scenarios and evaluate the resulting production benefits.

-

Explore the transformative potential of data integration and intelligent algorithms for enhancing monitoring precision.

-

Evaluate the techno-economic justification for investing in high-accuracy equipment through a detailed cost-benefit analysis.

3.0 Foundational Principles: A Systematic Review of Inline Viscometer Technology

3.1 Classification of Inline Viscometers

Inline viscometers provide continuous, real-time measurements within a process stream, offering a significant advantage over slow, intermittent lab-based testing. These instruments operate on various physical principles, each with distinct advantages and limitations.

-

Vibrational Viscometers: These devices function by measuring the damping effect a fluid has on a vibrating element, such as a blade or tuning fork. The viscous drag of the fluid restricts the vibration, and this change in amplitude is converted into a viscosity signal. A key advantage of this technology is the absence of moving parts, which results in a highly durable, low-maintenance design that is largely unaffected by external factors like flow velocity, vibrations, or dirt particles.

-

Rotational Viscometers: This is a widely used technology, where a spindle is immersed in a fluid and rotated at a constant speed. The instrument measures the torque (rotational force) required to maintain that speed; this torque is directly proportional to the fluid's viscosity. Rotational viscometers can use different torque-measuring systems. The spring system, based on a pivot and spring assembly, offers high measurement accuracy, particularly in low viscosity ranges, but is more delicate and has a limited measuring range. In contrast, the servo system uses a precision servo motor and can cover a wide range of viscosities in a single instrument, offering greater robustness at the cost of slightly lower accuracy for low-viscosity fluids and slow speeds.

-

Hydrodynamic Viscometers: This principle is based on the pressure change induced by fluid flow through a wedge-shaped gap formed by a rotating rotor and a static outer surface. The displacement of the outer surface, which acts as a spring, is measured by an inductive sensor and is proportional to the fluid's viscosity. This design is particularly robust in harsh conditions, as its measurement principle is decoupled from potential bearing friction and is not easily influenced by process fluid properties.

3.2 Key Performance Metrics

For any inline viscometer, the key metrics are its accuracy and repeatability. Accuracy is defined as how close a measurement is to the fluid's true viscosity value, while repeatability is the ability to produce consistent results across multiple, successive tests of the same sample under identical conditions. These two metrics are paramount for reliable process control. Without a stable and repeatable signal, a control system cannot make confident adjustments, and without accuracy, any adjustments made are based on an erroneous understanding of the fluid's true state.

3.3 Table 1: Viscometer Technology Comparison Matrix

This table provides a concise overview of the technical and operational trade-offs between the primary types of inline viscometers, serving as a rapid decision-making tool for technology selection.

|

Metric |

Vibrational |

Rotational |

Hydrodynamic |

|

Operational Principle |

Measures the damping of a vibrating element. |

Measures torque to maintain a constant rotational speed. |

Measures pressure change in a wedge-shaped gap created by a rotating cylinder. |

|

Key Advantage(s) |

No moving parts, highly durable, low maintenance, insensitive to flow and particles. |

Versatile with wide measurement range; can handle both thin and thick fluids. |

Resilient in harsh conditions, measurement is decoupled from bearing friction. |

|

Key Disadvantage(s) |

Not explicitly stated, but may have limitations in certain high-viscosity applications. |

Servo systems may have lower accuracy for low viscosities and speeds. |

Requires a rotating element and precise gap geometry, potentially sensitive to wear. |

|

Maintenance |

Generally maintenance-free with long working life.21 |

Requires periodic calibration checks, especially for spring systems; subject to mechanical wear. |

Requires robust mechanical components; long-term wear can affect accuracy. |

|

Suitability for Non-Newtonian Fluids |

Damping effect may be complex; specific models are required. |

Can handle non-Newtonian fluids by varying shear rate. |

Can be designed to measure at different speeds to characterize fluid behavior. |

|

Sensitivity to Environmental Factors |

Insensitive to vibrations, flow velocity, and dirt particles. |

Sensitive to turbulence and improper spindle selection. |

Can be affected by high speeds leading to turbulent flow and centrifugal forces. |

|

Example Application |

Fuel oil combustion control on ships. |

Production of paints, coatings, and adhesives. |

Monitoring in harsh industrial processes with abrasive fluids. |

4.0 A Systematic Analysis of Error and Precision in Industrial Viscometry

Even the most advanced inline viscometers can produce erroneous readings if the various sources of error are not fully understood and mitigated. These sources can be broadly categorized into fluid-specific issues and instrumental or procedural factors. A failure to address these can lead to a cascade of negative business outcomes.

4.1 Sources of Measurement Inaccuracy and Non-Repeatability

-

Fluid-Specific Errors: The inherent properties and condition of the fluid itself represent a primary source of error. Viscosity is extremely sensitive to temperature; even a shift of just one or two degrees can cause a significant change in a reading. The lack of proper temperature compensation can render an entire measurement dataset useless. Many industrial fluids, such as drilling muds or polymer solutions, are non-Newtonian, meaning their viscosity changes with shear rate. Using a viscometer that operates at a single, undefined shear rate can lead to highly misleading results for these fluids. Furthermore, contamination from air bubbles, particles, or other process fluids can cause erroneous and unstable readings, a particular concern for inline systems that cannot be easily pre-treated.

-

Instrumental & Procedural Errors: The instrument itself and the protocols governing its use are another key factor. All viscometers are susceptible to "drift" over time due to mechanical wear and environmental exposure, necessitating regular, traceable calibration with standard fluids to ensure accuracy. The choice of sensor and its setup is also critical. For rotational systems, using the wrong spindle or speed can lead to turbulent flow, which distorts readings, especially for low-viscosity fluids. Similarly, incorrect sensor placement or immersion can cause deposits and lead to inaccurate data. Finally, the harsh operating environment itself—including vibrations from pumps and heavy equipment, as well as extreme pressures and flow velocities—can compromise the accuracy and repeatability of certain viscometer technologies.

4.2 The True Cost of Inaccuracy

An inaccurate viscometer reading initiates a direct and consequential chain of negative events. First, the control system receives a false signal, leading to an incorrect adjustment of a process parameter, such as adding too much diluent to a fluid or improperly adjusting pumping pressure. This incorrect action results in an immediate operational failure, such as an off-spec batch of product, inefficient energy consumption, or excessive equipment wear. This operational failure then ripples through the business, creating broader implications that include increased costs from material waste, reduced yield, potential product recalls, and even regulatory non-compliance. These hidden costs of inaccuracy represent a significant business risk that far outweighs the cost of investing in a more precise instrument.

4.3 Table 2: Common Viscometer Error Sources and Mitigation Strategies

This table serves as a practical diagnostic and proactive planning tool, mapping specific sources of error to their observable effects and recommended mitigation strategies.

|

Error Source Category |

Specific Error |

Observable Effect |

Recommended Mitigation |

|

Fluid |

Temperature Instability |

Drifting or fluctuating readings. |

Use integrated temperature sensors and compensation algorithms. |

|

Fluid |

Non-Newtonian Behavior |

Inconsistent readings at different shear rates. |

Select a viscometer that can operate at variable shear rates. |

|

Fluid |

Contamination (air bubbles, particles) |

Unstable or non-repeatable results. |

Implement proper sample handling or select a viscometer that is insensitive to particles. |

|

Environmental |

Vibration & Plant Noise |

Unstable or non-repeatable readings. |

Select a robust technology like a vibrational viscometer, which is insensitive to these factors. |

|

Environmental |

Flow Velocity & Pressure |

Unstable readings, turbulence, or erroneous data. |

Install sensors in a bypass line or choose a viscometer that is unaffected by flow velocity. |

|

Instrumental/Procedural |

Sensor Drift |

Gradual change in readings over time. |

Implement a routine, traceable calibration schedule using certified reference standards. |

|

Instrumental/Procedural |

Improper Spindle/Speed Selection |

Unreliable readings (e.g., torque below 10%). |

Choose the correct spindle and speed to ensure a stable, non-turbulent reading. |

5.0 Translating Accuracy into Production Outcomes: Case Studies and Industrial Benefits

The benefits of high-accuracy viscometry are not theoretical; they translate directly into tangible improvements across the oil and gas value chain.

5.1 Applications Across the Oil & Gas Value Chain

-

Drilling Fluids: The viscosity of drilling muds is critical for efficient and safe drilling operations. As demonstrated in a project in the Marcellus Shale, real-time viscometer data can guide immediate adjustments to drilling mud viscosity, ensuring optimal performance and wellbore stability in varying rock formations. This proactive approach prevents drilling complications and enhances overall efficiency.

-

Pipeline Transportation: The exceptionally high viscosity of heavy crude oil is a significant obstacle for transportation, requiring viscosity reduction through heating or dilution. By providing continuous, accurate measurements, inline viscometers enable real-time control over these processes. This ensures the fluid remains within regulatory viscosity standards for pipeline transport while minimizing the energy required for pumping and reducing the costs associated with excessive diluent use.

-

Refining & End-Product Control: Viscosity is a key quality metric for refined products like lubricants and fuels. A major European oil refinery, for example, uses inline viscometers to continuously monitor residue oil viscosity, providing data to an automated control loop that optimizes atomization before combustion. This process ensures complete combustion and reduces harmful deposits, extending engine lifespan and improving overall performance.

5.2 The Proactive Advantage of Precision

A key distinction between traditional and advanced viscosity monitoring lies in the shift from reactive to proactive control. A system with low-accuracy viscometers or one that relies on delayed lab results operates reactively; it detects a deviation from a setpoint after it has already occurred. The operator or an automated system must then initiate a corrective action, which results in periods of off-spec production, material waste, and downtime. In contrast, a high-accuracy inline system provides a stable, reliable signal in real time. This allows for immediate, precise, and automated adjustments to maintain setpoints before a significant deviation can occur. This proactive capability minimizes product variability, reduces defects, and maximizes throughput and yield, all of which directly and positively impact the bottom line.

6.0 The Next Frontier: Integrating Intelligent Systems and Sensor Fusion

The true potential of high-accuracy viscometry is fully realized when the data is no longer treated in isolation but is integrated into a larger, intelligent ecosystem of process monitoring.

6.1 The Power of Data Integration

High-accuracy viscometers become strategic assets when their data is combined with other critical process variables, such as temperature, pressure, and flow rate. This data integration provides a more comprehensive and accurate picture of the overall system condition. For example, a complete mass flow measurement can be achieved by combining a high-accuracy viscometer with a positive displacement flowmeter, providing a more reliable measure of fuel consumption in kilograms rather than just liters. This integrated data allows for more nuanced and accurate parameter adjustments.

6.2 The Rise of Intelligent Algorithms

Advanced analytics and machine learning (ML) are transforming how viscosity data is interpreted and utilized. ML algorithms like k-NN (k-nearest neighbor) and SVM (support vector machine) can be trained on viscometer data to calculate viscosity with remarkable accuracy, achieving up to 98.9% accuracy for unknown fluids in one study.

Beyond simple calculation, the most significant advancement lies in predictive maintenance and anomaly detection through sensor fusion. This approach involves combining data from multiple sources—including viscometers, temperature sensors, and vibration monitors—and analyzing them with deep learning models, such as the SFTI-LVAE framework. This model creates a continuous "health index" for a system, correlating subtle, multivariate changes in the data with early signs of degradation. One study on lubricating oils demonstrated that this method could provide an early warning of lubrication failure up to 6.47 hours in advance with a 96.67% detection accuracy and zero false alarms.

6.3 From Control to Prediction

The integration of intelligent algorithms represents a fundamental shift in operational philosophy. A traditional system is a simple control loop that reacts to a viscosity change. An AI-powered system, however, analyzes viscometer data in a broader context with other sensor inputs, identifying subtle trends that would be missed by a human operator or a simple algorithm. This transition from an automated, reactive system to a predictive, intelligent one enables "autonomous maintenance". It elevates the operator's role from reactive troubleshooting to strategic oversight, leading to dramatic reductions in system downtime, decreased maintenance costs, and a more effective service life for expensive equipment.

7.0 Techno-Economic Analysis: Investment Justification and ROI Framework

7.1 Total Cost of Ownership (TCO) Analysis

The initial investment for a high-accuracy inline viscometer can range from approximately $1,295 for a basic lab unit to over $17,500 for a professional-grade inline system. However, a low entry price does not necessarily mean a low TCO. A comprehensive TCO analysis must account for the full lifecycle of the equipment, including initial purchase and installation costs, ongoing maintenance requirements, calibration frequency, and the potential costs of process downtime. Systems designed for low maintenance and long-term stability, such as those with no moving parts, can offer a lower TCO over their operational life despite a higher initial cost.

7.2 Quantifying the Return on Investment (ROI)

The ROI for investing in high-accuracy viscosity control is realized through a combination of tangible, quantifiable savings.

-

Fuel & Energy Savings: Real-world case studies of fleet operators demonstrate that optimizing engine oil viscosity can lead to a 1.5% to 2.5% reduction in fuel costs. This is due to reduced internal friction within the engine, requiring less energy to pump the oil and improving overall fuel economy. These principles translate directly to industrial applications like pipelines and refining, where optimizing the viscosity of crude oil can significantly lower energy consumption for pumping.

-

Material Savings: Precision viscometry minimizes waste of expensive materials. For example, in coating applications, saving as little as 2% of coating material can lead to a short payback period for the equipment.

-

Labor & Maintenance Savings: Automated viscosity control systems can significantly reduce the need for manual testing and labor-intensive adjustments. One case study involved a company that reduced a six-person touch-up crew to a single individual by stabilizing their process with an automated system. This frees up personnel for other, higher-value tasks.

-

Defect Reduction & Yield Improvement: Tightly controlling viscosity reduces the incidence of defects and off-spec products, which translates to higher yields and reduced costs from rework or product recalls.

7.3 Table 3: Cost-Benefit Analysis: ROI Modeling

This framework quantifies the financial justification for investing in high-accuracy viscosity monitoring, providing a clear model for capital expenditure decisions.

|

Investment Costs (Initial & Ongoing) |

Annualized Operational Savings |

Financial Metrics |

|

Equipment Costs: $1,295 to $17,500+ per unit |

Fuel/Energy Savings: 1.5-2.5% reduction from optimized flow |

Average Payback Period: ~9 months |

|

Installation: Site alterations may be costly |

Material Savings: 2% reduction in expensive material usage |

Return on Investment (ROI): High, driven by multiple savings streams |

|

Maintenance/Calibration: Frequency depends on viscometer type and use |

Labor Savings: Reduced manual testing and need for rework crews |

Risk Reduction: Minimized risk of product recalls and non-compliance 26 |

|

Downtime Costs: Reduced by real-time control |

Yield Improvements: Reduced defects and off-spec products |

The accuracy of inline viscometers is not a minor technical specification but a fundamental determinant of operational and financial performance in the oil and gas industry. The analysis consistently demonstrates that high-accuracy systems are essential for moving from a reactive, corrective operational model to a proactive, real-time, and ultimately, predictive one. This shift yields tangible, quantifiable benefits, including significant cost reductions, improved product quality, and enhanced process efficiency. The future of viscosity monitoring lies in the convergence of high-precision hardware with intelligent software, enabling a new era of data-driven, autonomous process control.

Post time: Aug-28-2025