Effective inline liquid density measurement methods reduce raw material costs, support uniform waterborne wood finish, and streamline the overall coating production process. Real-time monitoring minimizes process variability, lowers raw material waste, and maximizes operational reliability. Consistent, high-purity output ensures stable quality for downstream applications in advanced coatings and other chemical sectors.

Ethyl Acetate Manufacturing Plant

*

Introduction

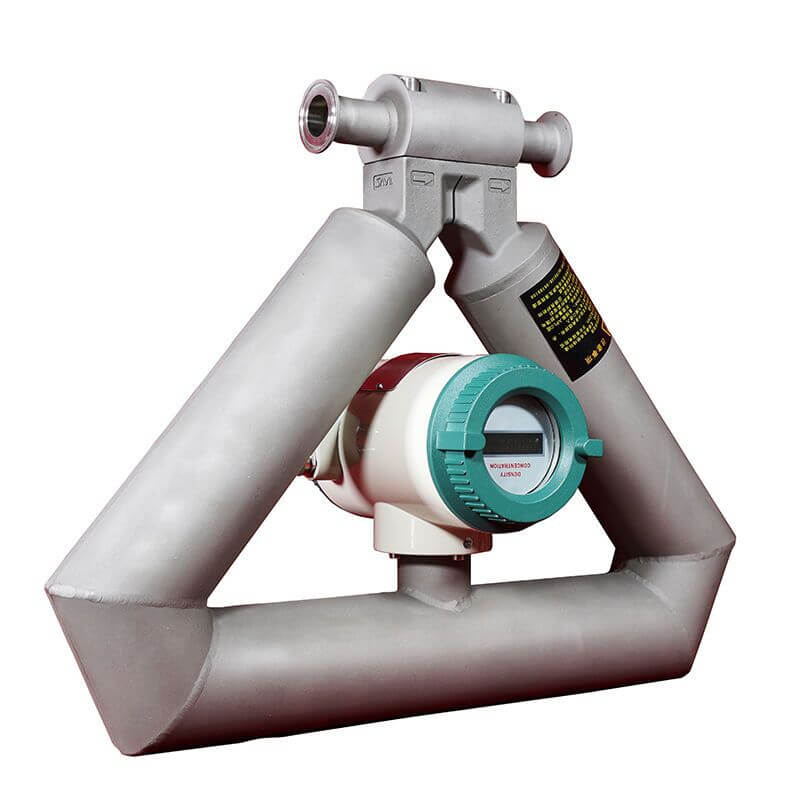

Precision in real-time liquid density measurement directly impacts ethyl acetate production efficiency and industrial coating quality. Inline density meters, such as vibrating tube and cantilever resonance sensors, reduce formulation errors, correcting density shifts in seconds. Research shows these sensors control ethyl acetate process yield above 95% using Fischer esterification, minimizing wasted acetic acid and ethanol. Automated inline measurements maintain stable density during process flow transitions—reaction, distillation, and blending—improving the eco-friendly performance of waterborne wood coatings. Real-time tracking prevents variability that leads to film cracking and paint sagging. Integrating inline concentration meters in coating production enables rapid adjustment of ingredient ratios for uniform dispersion and emulsification. Lonnmeter’s inline instruments measure density, viscosity, and temperature for advanced, sustainable coating manufacturing using ethyl acetate, eliminating batch inconsistency and optimizing every production step.

Overview of Ethyl Acetate Production Process

The ethyl acetate production process employs Fischer esterification, achieving yields above 95% with controlled parameters. The typical ethyl acetate process flow diagram presents three main stages: reaction, distillation, and purification. During the reaction stage, ethanol reacts with acetic acid, using sulfuric acid as a catalyst under continuous temperature and pressure regulation.

Inline density measurement integrates at critical points, including the reaction vessel, separation units, and blending tanks. Lonnmeter instruments enable real-time density tracking, optimizing phase separation and distillation cut points. Inline liquid density monitoring at these stages prevents off-spec products and supports water removal during purification.

Precise density control is vital for subsequent waterborne wood coating formulations. Consistency in liquid properties ensures stable viscosity, minimizing causes of film cracking and paint sagging in eco-friendly wood coatings. Integrated inline density meters provide immediate feedback, promoting uniformity and reliable performance in industrial coating manufacturing steps.

Production of ethyl acetate by chemical method and biological method

*

Industrial Coating Production and Waterborne Wood Coatings

Waterborne wood coatings rely on ethyl acetate as a primary solvent for rapid film formation and surface uniformity. The ethyl acetate production process must deliver high-purity output to meet demanding coating standards. Mixing, dispersion, and emulsification steps require controlled solvent concentrations to prevent phase separation and inconsistent film properties.

Industrial coating manufacturing steps—ingredient blending, homogenization, filtration, and packaging—demand real-time monitoring of solvent concentrations. Density-controlled dispersion reduces paint sagging causes and fixes flow inconsistencies triggered by fluctuating viscosities. Liquid density measurement methods improve process consistency and ensure eco-friendly wood coatings feature uniform gloss, durability, and drying rates. Preventing stratification and agglomeration guarantees a consistent waterborne wood finish for high-performance industrial use.

Real-Time Density Measurement Challenges

Feedstock variability in the ethyl acetate production process directly impacts esterification kinetics. Impurities, water content, and fluctuating reactant ratios shift reaction rates and alter density profiles, resulting in inconsistent product concentration. Process temperature may swing by ±5°C, and pressure changes of over ±0.1 bar interfere with precise liquid density measurement methods, requiring inline temperature transmitter and inline pressure transmitter inputs to correct readings.

Suspended solids and shifts in viscosity complicate sensor accuracy. Inline density meters and inline viscosity meters from Lonnmeter can be affected if particle load rises above 50 μm or viscosity exceeds 2000 cP, distorting readings. Batch-to-batch variations—common in industrial coating manufacturing steps—increase uncertainty in controlling end-product properties, especially when raw material sources change weekly.

Particle settling and flow stratification, prevalent when blending waterborne wood coatings, lead to unreliable density signals in multiphase flows. Density gradients of 0.02 g/cm³ may develop within pipelines or tanks, causing deviations in waterborne wood finish. These challenges emphasize the need to measure density of liquid under tightly controlled conditions for eco-friendly wood coatings.

Benefits of Integrating Inline Density Meters/Concentration Meters

Inline density meters and concentration meters, such as those from Lonnmeter, maximize process control in the ethyl acetate production process. They deliver immediate detection of off-spec solutions, enabling rapid adjustment in the Fischer esterification step or during blending. Real-time data reduces process deviations, increasing yield consistency above 95%.

Continuous inline liquid density measurement methods help maintain product purity during distillation and purification. This minimizes costly rework and raw material waste, vital for efficient ethyl acetate manufacturing.

In the coating production process for waterborne wood coatings, inline density control ensures each batch delivers uniform film formation. Stable density greatly decreases film cracking causes and prevention efforts as it curbs solvent imbalance. It also directly reduces paint sagging causes and fixes, ensuring consistent application and drying.

Request a tailored quote for inline density meter. Address critical challenges in the ethyl acetate production process by implementing precise liquid density measurement methods. Enhance industrial coating manufacturing steps, from the ethyl acetate process flow diagram to waterborne wood coatings application. Solve film cracking causes and prevention issues, mitigate paint sagging causes and fixes, and optimize your eco-friendly wood coatings process by measuring the density of liquid directly inline. Secure consistent formulation, reduce waste, and improve waterborne wood finish quality.

Post time: Jan-26-2026