Precise inline density measurement are essential in acetonitrile (methyl cyanide) production. Acetonitrile’s high volatility and complete miscibility with water complicate separation, requiring continuous data for accurate solvent recovery and yield optimization.

Inline chemical density reduces off-spec batches and material loss in continuous manufacturing environments. Real-time measurement is fundamental for API quality assurance, effective solvent recovery, and reducing environmental impact from neonicotinoids byproduct management.

What Are Neonicotinoids

*

Process Flow of Acetonitrile Production

Industrial acetonitrile (methyl cyanide) production relies on three principal pathways: condensation reaction, nucleophilic substitution, and ester exchange. The major route is a by-product of acrylonitrile manufacture, requiring fractional distillation for separation. Direct catalytic condensation of acetaldehyde with ammonia and air over bismuth molybdate produces acetonitrile, but accounts for a minor share due to lower yields.

Nucleophilic substitution uses haloethanes and cyanides, giving CH₃CH₂CN, but is rare at scale due to feedstock hazards and lower cost-effectiveness. Ester exchange, such as methanolysis of acetamide, has low industrial yield. Acetonitrile’s boiling point (81.6°C) and full miscibility with water challenge separation—inline density measurement optimizes recycle and purification stages.

Acetonitrile is valued as a polar aprotic solvent in organic intermediate and API synthesis, with essential roles in neonicotinoid insecticide manufacturing. Accurate solvent management increases purity, yield, and safety in recrystallization and downstream processing.

Density Monitoring Challenges in Acetonitrile Production

Rapid process kinetics in acetonitrile production require real-time monitoring to manage fast reaction rates and transient intermediates. Condensation reaction mechanisms, such as those in ammoxidation pathways, demand immediate feedback due to temperature and pressure sensitivity. Variable feedstocks from renewable and fossil sources introduce swings in methyl cyanide concentration, impacting downstream steps. Inline density measurement detects these shifts instantly, maintaining target ranges even with bioethanol or ammonia impurities.

Exact solvent control is critical in recrystallization steps for purity, as acetonitrile’s full miscibility with water easily disrupts separation efficiency by 5–10%. Precise acetonitrile as a polar aprotic solvent is essential for neonicotinoid insecticide synthesis, where a 0.5% deviation in concentration can lower product yield by up to 3%. Inline measurement prevents off-spec batches in continuous flow systems, cutting solvent waste by up to 8% and reducing downstream reprocessing events.

chemical structures of common neonicotinoids insecticides

*

Inline Density Measurement Techniques

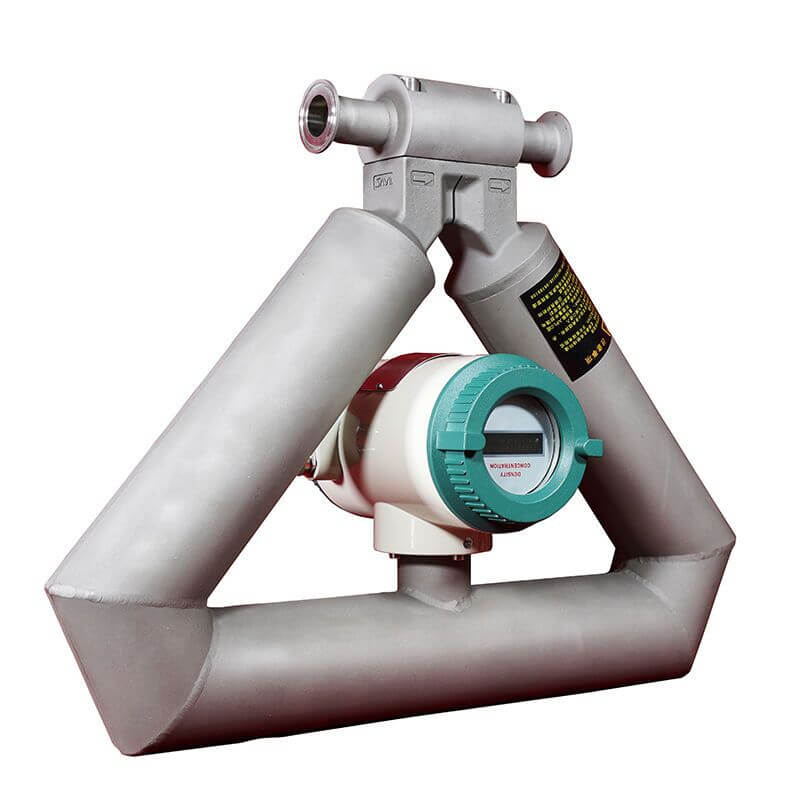

Inline density meters such as vibrating tube and Coriolis-based sensors deliver continuous, real-time data on acetonitrile concentration during organic synthesis. Chemical density meters from Lonnmeter correlate directly with acetonitrile’s physical properties, supporting automation without manual sampling. These inline sensors function under aggressive thermal and flow conditions common in condensation reaction and nucleophilic substitution processes.

Vibrating tube density meters measure midstream, providing ±0.001 g/cm³ accuracy even with volatile compounds like acetonitrile. Coriolis instruments offer dual density and flow feedback. Both withstand temperatures typically ranging from -20°C to 120°C and pipeline pressures up to 3 Mpa. These devices maintain process integrity when handling acetonitrile’s high volatility and complete miscibility with water.

Consistent inline measurement optimizes feed ratios in nucleophilic substitution, closes feedback loops in ester exchange, and minimizes yield loss from off-spec batches. Inline monitoring also enables robust API manufacturing and supports strict purity requirements in pharmaceutical and neonicotinoid synthesis.

Benefits of Integrating Inline Density/Concentration Meters

Inline density meters enable immediate detection of process deviations in acetonitrile production, supporting continuous purity and reducing correction lags. Real-time inline measurement sustains exact acetonitrile properties needed for precise condensation reaction and nucleophilic substitution. Consistent concentration control prevents off-spec product during methyl cyanide manufacturing, cutting material losses by up to 15% compared to offline sampling.

Lonnmeter inline instruments integrate with harsh process environments, maintaining reliable output during rapid ester exchange reaction or solvent-rich phases. Enhanced monitoring during recrystallization steps safeguards product purity, allowing organic synthesis to reach yields above 98%. Accurate data flow informs robust solvent management, minimizing contamination risk in active pharmaceutical ingredient (API) production.

In neonicotinoids insecticides synthesis, stable acetonitrile levels optimize reaction yield and suppress unwanted byproduct formation. Inline measurement slashes environmental loss linked to neonicotinoid manufacturing by providing precise solvent tracking, aiding compliance and sustainability efforts.

Solve Inline Density Challenges in Acetonitrile Production

Request a tailored quote to solve inline density measurement challenges and strengthen control in acetonitrile production, including properties and uses of methyl cyanide, polar aprotic solvent applications, and environmental requirements for neonicotinoid processes.

Post time: Jan-27-2026