Emulsions permeate industries such as food, cosmetics, oil and gas, agriculture, chemicals, pharmaceuticals, and beyond. It’s prone to separate without rigorous management and processing. Explore inline viscosity measurement solutions from Lonnmeter and optimize your process lines.

What Are Emulsions?

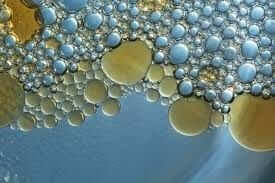

Emulsions are sophisticated mixtures where two immiscible liquids coexist, with one distributed as fine droplets within the other. Oil-in-water and water-in-oil is two types of emulsions. Oil-in-water (O/W) emulsions, such as milk, feature oil droplets in an aqueous medium, while water-in-oil (W/O) emulsions, like margarine, suspend water in a fat matrix.

How Emulsions Form and Break

Emulsions are produced by agitating two immiscible liquids with additions like emulsifiers to reduce interfacial tension. However, emulsions are thermodynamically unstable, susceptible to breakdown through:

- Creaming/Sedimentation: Droplets rise or settle due to density differences, as seen in unhomogenized milk.

- Flocculation: Droplets cluster due to van der Waals forces, reversible with agitation.

- Coalescence: Droplets merge, leading to phase separation, often from insufficient emulsifiers.

- Ostwald Ripening: Smaller droplets dissolve, feeding larger ones, altering particle size distribution.

- Phase Inversion: The dispersed and continuous phases swap, fundamentally changing the emulsion’s identity.

These mechanisms highlight the critical role of viscosity in maintaining emulsion stability.

The Role of Viscosity in Emulsion Quality

Viscosity is a indicator of resistance to flow, and determines emulsion stability and performance. It influences sensory attributes, such as the throat-coating effect of cough syrup or the spreadability of cosmetic creams. A common misconception, particularly in cosmetics, equates high viscosity with quality or solids content. In reality, a low-viscosity emulsion can have high solids, offering superior performance, such as faster drying in coatings. Precise emulsion viscosity control ensures consistent functionality and consumer satisfaction.

Factors Influencing Viscosity

Several factors dynamically shape emulsion viscosity:

- Temperature: Higher temperatures reduce viscosity by weakening intermolecular forces, making liquids flow more freely.

- Shear Rate: Non-Newtonian emulsions exhibit shear-thinning (e.g., shampoos flow under pressure) or shear-thickening behavior, critical for application-specific performance.

- Thixotropy: Time-dependent viscosity recovery, as in toothpaste, ensures it stays on the brush after dispensing.

- Concentration: Higher emulsifier or dispersed phase concentrations increase viscosity due to enhanced intermolecular interactions.

- pH and Ionic Strength: Affect emulsifier performance, altering viscosity and stability.

- Droplet Size: Smaller droplets increase viscosity due to greater surface area and interactions.

Impact on Processing

Lowering the dispersed phase’s viscosity (e.g., through heating) reduces interfacial tension, facilitating emulsion formation. Conversely, higher continuous-phase viscosity enhances emulsion stability by slowing droplet movement, reducing creaming. Balancing these dynamics is crucial for efficient emulsion processing, making viscosity monitoring indispensable.

IV. Challenges of Traditional Offline Viscosity Measurement

Offline emulsion viscosity measurement methods, such as viscosity cups or lab viscometers, are outdated for modern production demands. These approaches provide only static snapshots, missing critical process fluctuations. Manual sampling is labor-intensive, increasing operational costs and downtime. The time-lag between sampling and analysis means quality issues, like creaming or coalescence, are detected too late, risking entire batches.

Batch-to-batch variations stem from raw material inconsistencies (e.g., polymorphs affecting dissolution rates) or processing variations (e.g., mixing speed altering droplet size). These lead to inconsistent emulsion viscosity, compromising product quality and brand trust. Without continuous feedback, offline methods cannot address root causes, perpetuating inefficiencies and waste.

V. Online Viscosity Monitoring: Technology and Principles

Concept of Online Monitoring

Online viscosity monitoring revolutionizes emulsion processing by providing continuous, real-time data directly from the production line. Unlike reactive offline methods, it enables proactive control, allowing immediate adjustments to maintain optimal emulsion viscosity. This shift ensures consistent quality and streamlines workflows, reducing the risk of defective batches.

Inline Viscometer Technologies

Several technologies excel in online emulsion viscosity measurement:

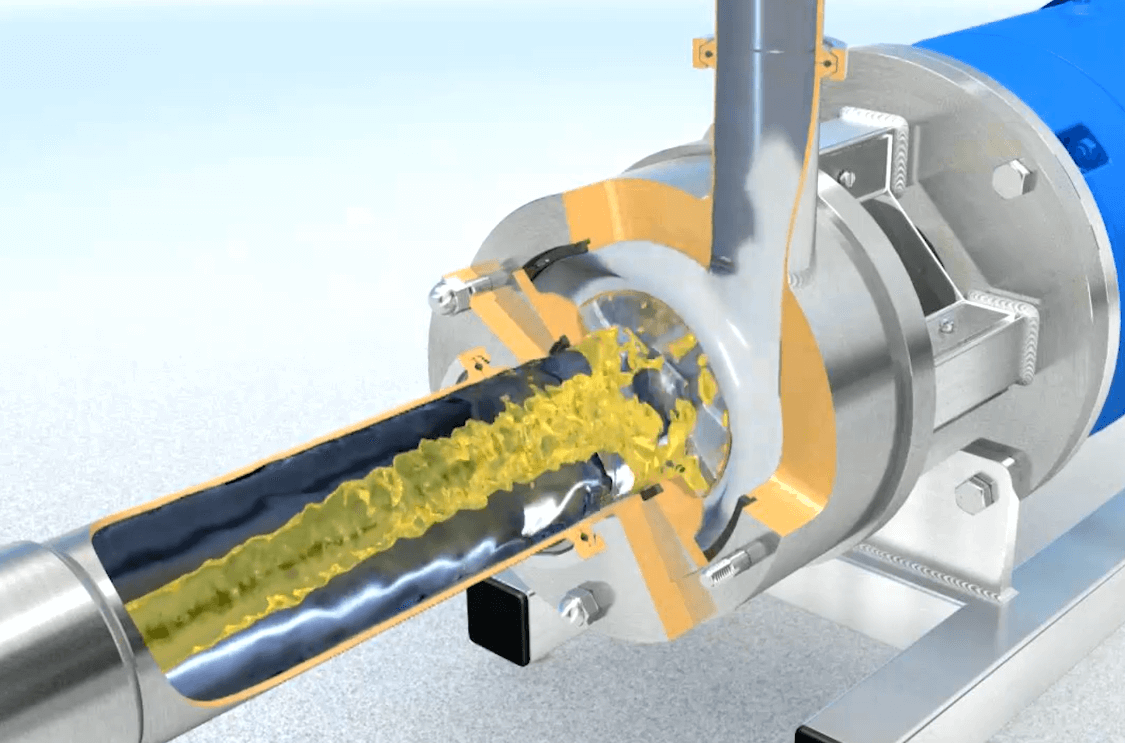

- Vibrational Viscometers: Devices like the Lonnmeter emulsion viscometer measure damping of a resonator immersed in the fluid. Their compact, vibration-resistant design is ideal for non-Newtonian emulsions, delivering stable, repeatable readings.

- Capillary Viscometers: Systems like the Gneuss Online Viscometer measure pressure drops in a capillary, offering high precision and cleanability without interrupting production, perfect for high-shear applications.

- Rotational Viscometers: These measure torque on a rotating spindle, versatile for complex rheology but less robust in fluctuating conditions.

Comparison Table: Inline Viscometer Technologies

|

Technology |

Principle |

Advantages |

Limitations |

Applications |

|

Vibrational |

Resonator damping |

Compact, vibration-resistant, high accuracy |

Sensitive to density changes |

Food, pharmaceuticals, cosmetics |

|

Capillary |

Pressure drop in capillary |

High precision, cleanable, no interruption |

Requires bypass loop, complex integration |

Polymer emulsions, high-shear |

|

Rotational |

Torque on rotating spindle |

Versatile, measures complex rheology |

Susceptible to fluctuations |

Creams, gels, lab testing |

Integration with Process Control

Inline viscometers integrate seamlessly with PLCs and SCADA systems, enabling automated adjustments (e.g., solvent dosing, mixing speed) based on real-time viscosity data. This closed-loop control ensures emulsion stability while data logging supports traceability for regulatory compliance in pharmaceuticals and food industries.

VI. Applications in Emulsion Formulation

Formulation Optimization

Real-time viscosity monitoring optimizes emulsifier selection and concentration, ensuring stable emulsions during formulation. It facilitates consistent scale-up from lab to pilot production, preventing issues like phase separation due to improper emulsifier levels. For example, monitoring emulsion viscosity during trials helps identify formulations resistant to flocculation.

Mixing Control

During emulsion processing, viscosity data guides adjustments to stirring intensity, temperature, or oil/water ratios. Overworking an emulsion—applying excessive shear without sufficient emulsifier—reduces droplet size, leading to instability. Real-time monitoring prevents such issues, ensuring optimal mixing conditions.

Predictive Stability

Viscosity serves as a predictor of emulsion stability, enabling formulators to fine-tune recipes. By correlating viscosity with stability metrics, manufacturers can accelerate development, reducing reliance on lengthy shelf-life tests.

VII. Applications in Emulsion Testing

Stability Assessment

Monitoring emulsion viscosity detects early signs of instability, such as creaming, flocculation, or coalescence. It supports accelerated testing methods, like centrifugation, to predict shelf life without static observations, saving time and ensuring product reliability.

Performance Validation

Viscosity correlates with functional properties, such as mouthfeel in food emulsions (e.g., salad dressings) or spreadability in cosmetics (e.g., lotions). Continuous monitoring ensures these attributes meet consumer expectations across batches.

Regulatory Compliance

Continuous viscosity data provides a documented record for FDA and EU standards, critical for audited industries like pharmaceuticals and food, ensuring process consistency and product safety.

VIII. Applications in Emulsion Processing

Process Optimization

Real-time viscosity monitoring optimizes emulsion processing parameters, such as shear rate or temperature, reducing cycle times. Ultra-high shear mixers, used as pre-mixers, minimize passes through high-pressure homogenizers, lowering energy and maintenance costs.

Troubleshooting

Inline viscometers detect issues like air entrainment, insufficient emulsifier, or flocculation, triggering real-time alerts. This proactive approach prevents defective batches and minimizes downtime.

Scalability

Maintaining consistent emulsion viscosity during large-scale production ensures quality across batches, critical for high-volume industries like food and coatings.

X. Benefits of Online Viscosity Monitoring

- Enhanced Quality: Consistent emulsion viscosity ensures stability, performance, and consumer satisfaction across food, cosmetics, and pharmaceuticals.

- Cost Savings: Reduced material waste and rework, with rapid ROI, as seen in the case study’s six-month payback.

- Process Efficiency: Automated adjustments streamline workflows, reducing production passes and energy use.

- Traceability: Continuous data supports regulatory compliance and process documentation.

- Competitive Advantage: Faster product launches and consistent quality differentiate brands in competitive markets.

- Calibration and Maintenance: Regular calibration ensures accuracy; automated cleaning systems handle sticky emulsions. Vibrational viscometers require minimal upkeep.

- Non-Newtonian Complexity: Vibrational viscometers excel for shear-thinning or thixotropic emulsions, addressing complex rheology.

- Integration: Compatibility with PLCs/SCADA is critical; training ensures seamless adoption.

- Initial Costs: Upfront investment is offset by long-term savings, as proven by the case study’s rapid ROI.

XI. Challenges and Solutions

Online viscosity monitoring redefines quality control in emulsion formulation, testing, and processing, replacing outdated offline methods with real-time, proactive solutions.

By ensuring consistent emulsion viscosity, it mitigates instability, enhances performance, and drives efficiency. Explore Lonnmeter’s solutions to elevate your emulsion process and achieve operational excellence.

Post time: Aug-21-2025