Perfect and consistent emulsion concentration is the cornerstone of product quality, operational efficiency, and cost savings. Emulsion concentration meters or emulsion concentration monitors provide real-time data to optimize the emulsion mixing ratio, ensuring consistent performance and compliance with industry standards. Explore how to enhance emulsion concentration measurement in the mixing of oil and water emulsions, offering actionable insights for cold rolling mill processes.

Significance of Emulsion Concentration

Emulsions, mixtures of oil and water stabilized by emulsifiers, are essential in cold rolling mill processes and asphalt production. Emulsions are used to lubricate and cool the metal in cold rolling.

In cold rolling, emulsions lubricate and cool the metal during rolling, ensuring high surface quality and dimensional accuracy. Inconsistent emulsion concentration can lead to defects, equipment wear, or environmental non-compliance. Emulsion concentration meters provide real-time monitoring to maintain optimal water oil ratio while reducing waste and enhancing efficiency. It’s an effective method to prevent surface scratches or roll overheating by maintaining an emulsion mixing ratio of 2%-10% oil content.

Challenges of Traditional Emulsion Monitoring

Traditional methods for emulsion concentration measurement are time-consuming and prone to errors. Offline sampling and laboratory analysis could not capture dynamic changes, too. Additionally, manual interventions increase labor costs and downtime, then to overall productivity further.

Effective Emulsion Concentration Measurement

Inline Emulsion Concentration Meters

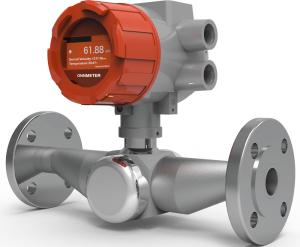

Emulsion concentration meters use advanced technologies like ultrasonic to measure the emulsion oil ratio in real time. These devices are installed directly in pipelines or tanks, providing continuous data without interrupting production. They infer the speed of sound by measuring the transmission time of sound wave from the signal source to the signal receiver. This measurement method is not affected by the conductivity, color and transparency of the liquid, ensuring extremely high reliability. Users can achieve a measurement accuracy of 0.05%~0.1%. The multi-functional ultrasonic concentration meter is able to measure Brix, solid content, dry matter or suspension.

Benefits of Inline Continuous Concentration Measurement

Inline emulsion concentration meters offer several advantages:

- Real-Time Feedback: Immediate data allows rapid adjustments to the water oil ratio, preventing process deviations.

- Non-Invasive Operation: Ultrasonic concentration meters require no sampling, reducing contamination risks.

- High Precision: Ensures consistent emulsion properties, critical for product quality in cold rolling.

- Versatility: Suitable for various emulsion types, from lubricants to asphalt binders.

Ultrasonic Emulsion Concentration Monitoring

Ultrasonic emulsion concentration monitoring stands out for its non-invasive, high-precision capabilities, particularly in cold rolling mill processes. By measuring the speed of sound waves through the emulsion, these monitors correlate velocity with emulsion concentration, unaffected by factors like color or conductivity.

This makes them ideal for dynamic environments where emulsions are subject to temperature or composition changes. This technology also supports how to mix oil and water emulsion by providing data to optimize mixing conditions, reducing phase separation risks.

Emulsion Concentration in Cold Rolling Mill Processes

In cold rolling mill processes, emulsions serve as lubricants and coolants, reducing friction between rolls and metal surfaces while dissipating heat. Maintaining an optimal emulsion oil ratio (typically 4%-6% for steel rolling) is crucial to prevent surface defects and equipment wear. Emulsion concentration monitors provide real-time data to adjust water or oil additions, ensuring consistent lubrication.

How to Optimize Emulsion Concentration Measurement in Mixing Oil and Water Emulsions

Step 1: Select the Right Emulsion Concentration Meter

To address how to optimize emulsion concentration measurement in mixing of oil and emulsion, start by choosing a meter suited to your industry. For cold rolling mill processes, ultrasonic emulsion concentration meters are ideal due to their precision and non-invasive design. Consider factors like emulsion type, operating conditions, and integration with existing control systems.

Step 2: Integrate with Automation Systems

Seamless integration with PLC or DCS systems is critical for real-time emulsion concentration measurement. Automated feedback loops adjust the mix oil and water emulsion process, maintaining the desired water oil ratio.

Step 3: Monitor and Adjust Mixing Conditions

Optimizing how to mix oil and water emulsion requires monitoring mixing parameters like shear rate, temperature, and emulsifier concentration. Emulsion concentration monitors provide data to fine-tune these variables, ensuring stable mixed emulsions.

Step 4: Train Staff and Maintain Equipment

Effective emulsion concentration measurement relies on trained operators who can interpret real-time data and make informed decisions. Regular calibration of emulsion concentration meters ensures accuracy, especially in harsh environments like cold rolling mills. Maintenance schedules should align with production cycles to minimize downtime.

FAQs About Emulsion Concentration Measurement

What Is the Role of Emulsion Concentration Meters in Cold Rolling?

Emulsion concentration meters ensure the correct emulsion oil ratio in cold rolling mill processes, optimizing lubrication and cooling. They reduce surface defects, equipment wear, and emulsion waste, improving quality and efficiency.

How Do Emulsion Concentration Monitors Improve Asphalt Production?

Emulsion concentration monitors maintain stable mixed emulsions in asphalt production, ensuring proper viscosity and adhesion. They reduce water usage and prevent emulsion breakdown, enhancing road durability and cost savings.

What Are the Cost Benefits of Real-Time Emulsion Concentration Measurement?

Real-time emulsion concentration measurement reduces material waste, energy consumption, and downtime. In cold roll mill processes, it can save 5%-10% on emulsion costs, while asphalt producers report 5%-8% savings on water and emulsifier usage.

Emulsion concentration measurement is a cornerstone of efficiency and quality in cold rolling mill processes. By leveraging emulsion concentration meters and emulsion concentration monitors, manufacturers can achieve precise control over the water oil ratio and emulsion mixing ratio, ensuring stable mixed emulsions.

These tools address how to optimize emulsion concentration measurement in mixing of oil and emulsion, delivering cost savings, enhanced product quality, and regulatory compliance. Whether you’re a cold rolling mill or asphalt producer, real-time monitoring transforms your operations. Contact our team for customized emulsion concentration meter solutions or visit our website for a free consultation today!

Post time: Jul-11-2025