The leather tanning process transforms raw animal hides into durable, flexible leather, a craft refined over centuries yet continually evolving with modern technology. Central to this process, particularly in the widely adopted chromium leather tanning process, is the precise management of chemical concentrations, such as sodium sulfate, to ensure superior leather quality and environmental compliance. Deviations in these concentrations can compromise the leather’s physical properties and escalate production costs, while traditional monitoring methods often fall short in addressing the challenges of corrosive media and real-time demands. This article explores the pivotal role of sodium sulfate concentration in chrome tanning, the intricacies of the process, the limitations of conventional monitoring, and the transformative benefits of advanced inline concentration meters, such as the Lonnmeter, in achieving precision and efficiency.

Chrome Concentration: The Cornerstone of Leather Quality

Chromium, primarily in the form of basic chromium sulfate (BCS), is the backbone of modern leather tanning, accounting for 80-90% of global leather production due to its ability to produce leather with exceptional hydrothermal stability, flexibility, and dyeing characteristics. The concentration of chromium in the tanning liquor directly influences the leather’s shrinkage temperature (Ts), tensile strength, and softness. For instance, research indicates that a 10.8% increase in Cr₂O₃ content in leather can enhance collagen fiber distribution and mechanical properties. However, the efficacy of chromium fixation hinges on the supporting chemicals, notably sodium sulfate, which stabilizes the tanning bath’s pH and aids in chromium penetration. Inconsistent sodium sulfate concentration can disrupt this delicate balance, leading to uneven tanning, poor chromium uptake, and compromised leather quality. Maintaining optimal concentrations is thus not merely a technical requirement but a critical determinant of the final product’s durability and aesthetic appeal.

The Leather Tanning Process

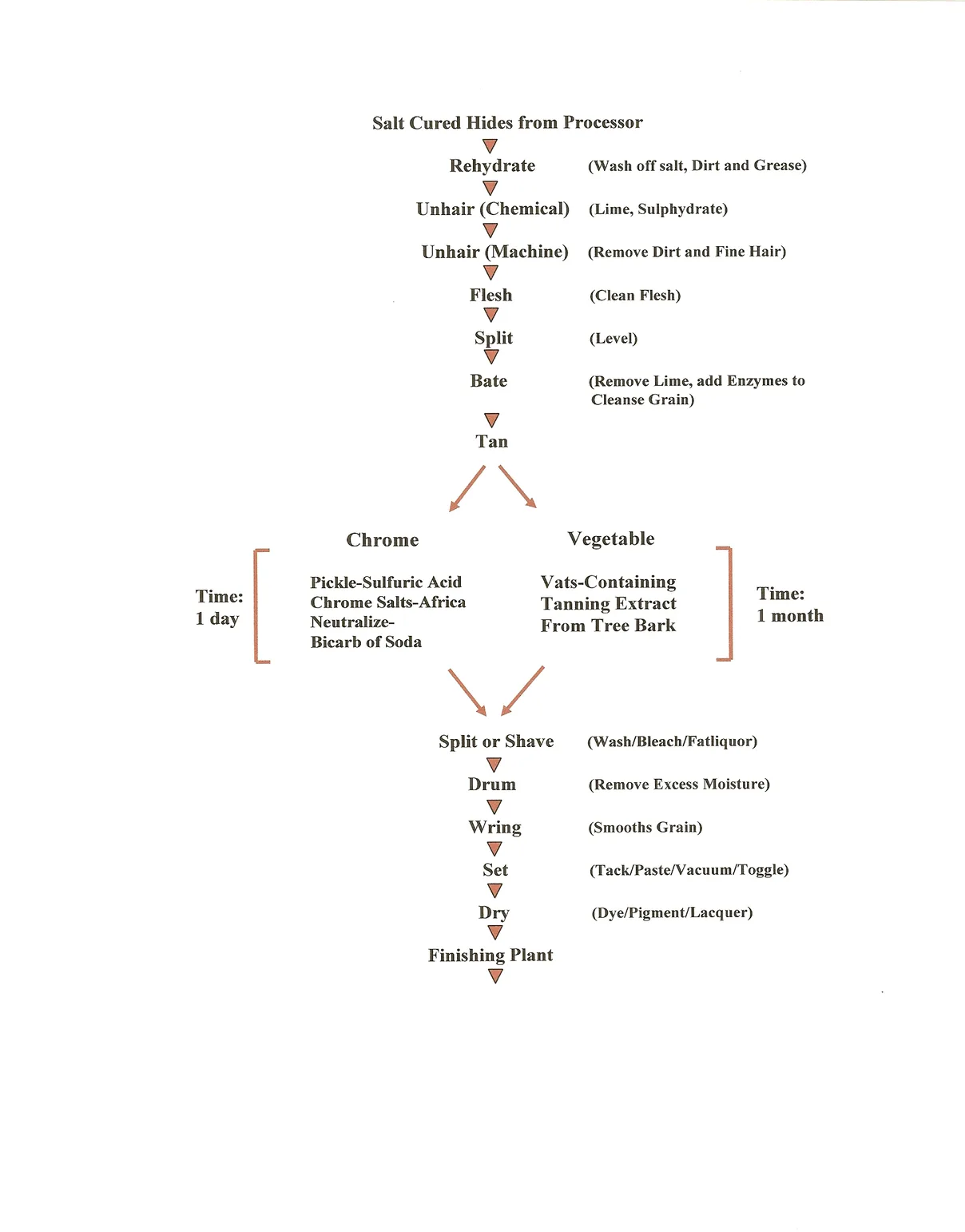

The leather tanning process is a complex sequence of chemical and mechanical steps designed to convert perishable hides into stable, versatile leather. It begins with beamhouse operations—curing, soaking, liming, unhairing, fleshing, deliming, bating, and pickling—preparing the hide for tanning by removing hair, fats, and proteins while adjusting its pH. The tanning stage follows, where the hide’s collagen fibers are chemically modified to enhance durability and resistance to decay. Post-tanning processes, including retanning, dyeing, and fatliquoring, refine the leather’s appearance and texture. Among the tanning methods, the chromium leather tanning process dominates due to its speed and ability to produce stretchable, high-quality leather suitable for applications like handbags, garments, and upholstery.

Overview of the Chromium Leather Tanning Process

The chromium leather tanning process is a streamlined, efficient method that typically completes tanning in under a day, a stark contrast to the weeks or months required for vegetable tanning. It involves several key steps:

- Soaking and Liming: Hides are soaked in water to rehydrate and remove salt from curing, followed by liming with calcium hydroxide and sodium sulfide to loosen hair and prepare the collagen matrix.

- Pickling: The hides are immersed in an acidic solution containing sodium chloride (6-8% by weight) and sulfuric or formic acid to lower the pH to 2.5-3.0, protecting collagen from acid swelling and facilitating chromium penetration.

- Tanning: Basic chromium sulfate (6-8% by pelt weight, containing ~25% Cr₂O₃) is introduced, penetrating the hide to form complexes with collagen. The pH is then raised to 3.8-4.0 using sodium bicarbonate in a basification step to promote cross-linking, resulting in “wet blue” leather characterized by its greyish-blue hue.

- Post-Tanning: Retanning, dyeing, and fatliquoring enhance the leather’s properties, with sodium sulfate playing a critical role in stabilizing solutions and aiding tanning agent fixation.

Sodium Sulfate in Post-Tanning Treatment

Sodium sulfate is integral to post-tanning, particularly in desalting and tanning agent fixation, ensuring consistent leather quality and environmental compliance.

- Desalting Process: High salt concentrations from pickling, primarily sodium chloride, contribute to elevated total dissolved solids (TDS) in effluents, posing environmental challenges. Sodium sulfate is used in desalting to reduce chloride levels, replacing up to 80% of sodium chloride in some processes. This substitution lowers TDS, with studies showing reductions up to 97% in eco-friendly tanning systems, mitigating the salinity of wastewater discharged into public sewers.

- Tanning Agent Fixation Process: Sodium sulfate stabilizes the tanning bath’s pH and enhances chromium uptake by moderating the reactivity of collagen and chromium complexes. It prevents over-quick surface tanning, ensuring uniform penetration. For example, maintaining a consistent sodium sulfate concentration can improve chrome uptake by 28.5%, reducing residual chromium in effluents from 2000-5000 mg/L to below 300 mg/L, aligning with stricter environmental regulations.

Impacts of Concentration Deviations on Process and Quality

Deviations in sodium sulfate concentration can profoundly affect the leather tanning process and the resulting product. Excessively high concentrations may lead to over-salting, causing collagen swelling, coarse grain, and reduced softness, while insufficient concentrations can result in inadequate chromium fixation, leading to uneven tanning and weak leather. Such inconsistencies increase shrinkage rates—studies report a rise from 1.3% to 5.2% with improper salt management—and elevate effluent chromium levels, exacerbating environmental pollution. Furthermore, high TDS from improper desalting strains wastewater treatment systems, increasing operational costs. Precise tanning solution concentration monitoring is thus essential to maintain leather quality and comply with environmental standards, such as the 20 mg/L total chromium limit for effluent discharge.

Challenges in Tanning Solution Concentration Monitoring

Monitoring sodium sulfate concentration in the chromium leather tanning process presents significant hurdles due to the harsh conditions and limitations of traditional methods.

- Drawbacks in Traditional Measurement: Conventional methods, such as titration or gravimetric analysis, are labor-intensive, time-consuming, and prone to human error. These offline techniques require sampling and laboratory analysis, delaying process adjustments and risking quality deviations.

- Corrosive Media: Tanning liquors, with their low pH (2.5-4.0) and high concentrations of acids, salts, and chromium, are highly corrosive, damaging traditional sensors and necessitating frequent maintenance or replacement.

- Requirements for Continuous Monitoring: The dynamic nature of tanning demands real-time data to adjust chemical inputs promptly. Batch sampling fails to capture rapid changes in sodium sulfate concentration, leading to inconsistent tanning and increased waste.

- Calibration and Accuracy: Traditional instruments often struggle with calibration in the presence of multiple ions, leading to inaccurate readings and unreliable process control.

- Environmental Compliance: Stringent regulations, such as those limiting TDS and chromium in effluents, require precise monitoring to avoid costly fines and ensure sustainable operations.

Advanced Lonnmeter Concentration Meter

The Lonnmeter chemical concentration meter represents a breakthrough in tanning solution concentration monitoring, designed to address the challenges of corrosive media and continuous monitoring. This advanced inline device employs robust sensor technology, resistant to acidic and saline environments, to deliver real-time, accurate measurements of sodium sulfate concentration. Unlike traditional methods, the Lonnmeter integrates seamlessly into tanning drums, providing continuous data without the need for manual sampling. Its high-precision sensors ensure reliable calibration, even in complex liquors, while its durable design minimizes maintenance, reducing downtime and costs. By enabling precise control of chemical inputs, the Lonnmeter enhances chromium uptake, reduces effluent pollutants, and supports compliance with environmental standards.

Benefits of Inline Concentration Measuring

Adopting inline concentration measuring with tools like the Lonnmeter transforms the leather tanning process by offering:

- Enhanced Process Efficiency: Real-time monitoring allows immediate adjustments, reducing chemical waste and optimizing tanning time. Studies show that inline systems can shorten tanning duration by up to one-third while improving chrome uptake by 13.8-28.5%.

- Improved Leather Quality: Consistent sodium sulfate concentration ensures uniform chromium penetration, enhancing leather’s tensile strength, tear resistance, and softness, with shrinkage rates as low as 1.3%.

- Environmental Sustainability: By minimizing residual chromium and TDS in effluents, inline monitoring supports eco-friendly tanning, reducing BOD, COD, and TDS by up to 88%, 89%, and 97%, respectively, in advanced processes.

- Cost Savings: Reduced chemical usage, lower effluent treatment costs, and decreased maintenance expenses improve operational profitability.

- Regulatory Compliance: Precise control aligns with stringent environmental regulations, avoiding penalties and supporting sustainable leather production.

- Data-Driven Decision Making: Continuous data feeds enable predictive maintenance and process optimization, enhancing overall tannery performance.

For tanneries seeking to elevate their chromium leather tanning process, the Lonnmeter Concentration Meter offers a proven solution to master sodium sulfate concentration control.Contact us today to request a quote (RFQ) for the Lonnmeter and discover how inline concentration measuring can revolutionize your tanning operations. Join the forefront of sustainable leather manufacturing with technology that delivers results.

Post time: Sep-01-2025