Viscosity is the master property that governs performance of fresh concrete mixture, influencing everything from its ability to be pumped to its resistance to segregation. Look into the comprehensive analysis of how a nuanced understanding and proactive management of concrete viscosity can make contributions to operational efficiencies, final product quality, and overall project costs. Continuous in-line measurement technologies and a data-driven approach to concrete mixing process can ensure the homogeneity and consistency for achieving a strong, durable, and reliable final product.

Necessaties of Scientific Viscosity Management in Mixing

The construction industry’s demand for materials with advanced properties, such as high-strength concrete (HPC), self-consolidating concrete (SCC), and specialized fiber-reinforced mixes, has exposed the limitations of traditional quality control measures. For nearly a century, the slump test has been the standard method for assessing the workability of fresh concrete. While simple and familiar, this single-parameter test is fundamentally inadequate for characterizing the complex flow behavior of modern concrete, often providing misleading results that fail to predict a mix’s true performance on-site.

The flow and deformation of fresh concrete, collectively termed rheology, are critical to its performance. The central factor influences rheology lies in concrete viscosity in mixing, which dictates how a concrete mix behaves from initial mixing to its final placement in formwork. Replace subjective and empirical tests with a continuous precise sensing technology for more accurate viscosity measurement.

1. The Rheological Fundamentals of Concrete

1.1 Defining Viscosity in a Complex Fluid

To understand the rheology of fresh concrete, it is essential to first recognize it not as a simple liquid but as a highly concentrated, heterogeneous suspension of solid particles in a viscous liquid. The continuous phase, or matrix, in concrete is a suspension of fine particles—including cement grains (with an average diameter of approximately 15µm), mineral additives (such as silica fume with an average diameter of 0.15µm), and sand particles smaller than 100µm—dispersed in water that contains chemical admixtures. The flow behavior controls the overall flow behavior directly and the processability of the entire concrete mix.

Unlike a Newtonian fluid, which has a constant viscosity at any shear rate, concrete exhibits non-Newtonian behavior. Its resistance to flow is not a single, fixed value. The term “apparent viscosity” describes the ratio between the applied shear stress and the resulting shear rate. This apparent viscosity changes as a function of the shear rate and the concentration of solid particles within the suspension, as well as the degree of particle flocculation. For practical purposes, the flow properties of fresh concrete are best characterized by a two-parameter model, which provides a more complete and useful description than a single-value measurement.

1.2 Essential Rheological Models: Bingham and Beyond

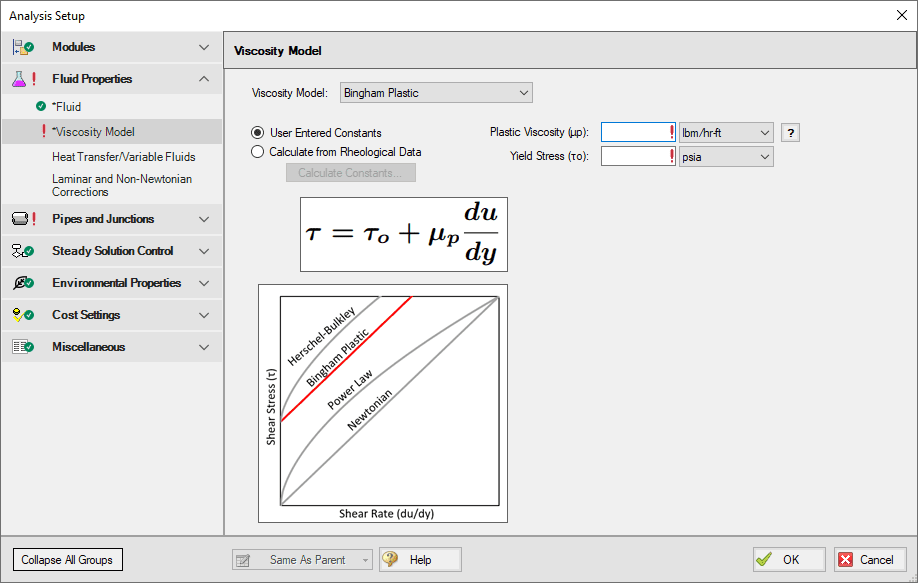

The flow of fresh concrete is most commonly and effectively described by the Bingham fluid model, which provides two fundamental rheological parameters to characterize its behavior: yield stress and plastic viscosity. These two parameters capture the dual nature of concrete’s flow.

-

Yield Stress (τ0): This parameter represents the minimum shear stress that must be applied to the fresh concrete before it begins to flow. It is the force required to break the temporary, inter-particle bonds and initiate motion. A mix with a high yield stress will feel stiff and resist initial movement, while a low yield stress indicates a mix that is highly flowable and will spread under its own weight.

-

Plastic Viscosity (μp): This is the measure of the material’s resistance to continued flow once the yield stress has been overcome. It is represented by the slope of the linear relationship between shear stress and shear rate. Plastic viscosity quantifies the internal friction and viscous drag within the fluid, which is crucial for processes like pumping and finishing.

For many advanced applications, such as highly flowable or shear-thickening mixes, more complex models like the Herschel-Bulkley model may be used. This model has three rheological parameters—yield stress, a consistency coefficient, and a consistency exponent—that can quantitatively describe yield stress, differential viscosity, and the degree of shear-thickening. However, for most conventional and high-performance concrete, the Bingham model provides a robust and practical framework for quality control.

The reliance on these dual parameters highlights a fundamental inadequacy of traditional quality control. The slump test, for instance, is a single-point measurement that is a function of a mix’s yield stress. This means a mix with the proper slump may still have an incorrect plastic viscosity, leading to significant on-site issues. For example, two different mixtures can produce the same slump value but have different pumpability or finishing characteristics, as one may have a very low plastic viscosity (making it hard to finish) while the other has an unacceptably high one (making it difficult to pump). A single-parameter test is thus insufficient for modern, performance-driven concrete, necessitating a shift to a more complete rheological characterization.

Table 1: Rheological Parameters and Their Physical Significance

|

Parameter |

Definition |

Physical Significance |

Governs Primary Fresh Concrete Property |

|

Yield Stress (τ0) |

The minimum shear stress required to initiate flow. |

The force required to get a mix moving. |

Slump, static segregation, formwork pressure. |

|

Plastic Viscosity (μp) |

The resistance to continued flow after motion begins. |

The resistance to flow once started. |

Pumpability, dynamic segregation, finishability. |

1.3 Key Factors Influencing Viscosity

The rheological properties of concrete are not static; they are highly sensitive to the proportions and characteristics of the constituent materials. A mix designer’s primary task is to balance these components to achieve the required strength and workability.

-

Water-Cementitious Materials Ratio (W/Cm): This is arguably the most significant factor. A lower W/Cm ratio, which is essential for achieving higher compressive strength and durability, also significantly increases the yield stress and plastic viscosity of the mix. This inverse relationship is the central paradox of mix design: achieving high strength often comes at the expense of workability, which necessitates a more nuanced approach to viscosity management.

-

Aggregate Properties: The characteristics of both coarse and fine aggregates are critical. The overall surface area of aggregates directly impacts the amount of paste needed for proper lubrication. Finer particles require more water and cement, thus increasing viscosity. Particle shape is also crucial; angular, crushed aggregates have a higher surface area and cause more inter-particle friction than rounded aggregates, requiring more paste to achieve the same workability.

-

Cementitious Materials: The fineness of cement and supplementary cementitious materials (SCMs) like fly ash and silica fume significantly impacts concrete performance. Finer particles with their larger surface area tend to increase flocculation and viscosity. Conversely, the spherical shape of fly ash particles can serve as a lubricant, lowering plastic viscosity and enhancing flowability.

-

Chemical Admixtures: Admixtures are specifically designed to manipulate concrete rheology. Water-reducing admixtures and superplasticizers disperse cement particles, reducing the water required for a given workability and thereby increasing final strength potential. Viscosity-modifying admixtures (VMAs) are used to provide the mix with cohesion and stability without adding extra water. They are critical for preventing segregation in highly fluid concrete and for specialized applications like underwater concrete and shotcrete.

The challenge of mix design is an interconnected optimization problem. The choice to lower the W/Cm ratio to increase strength is possible reduce workability by increasing viscosity. The addition of a superplasticizer can restore workability, but this newfound fluidity can, in turn, increase the risk of bleeding and segregation. Therefore, a viscosity-modifying admixture is needed to provide the necessary cohesion. This intricate and multi-variable dependency illustrates that concrete mixing process is not a simple linear process but a complex system where precise viscosity management is the central challenge. The selection and proportioning of one component directly influence the required proportions of others, making a holistic, rheology-based approach essential for success.

2. Dynamic Viscosity Management

2.1 The Limitations of Traditional Tests

The slump test remains the most widely used field test for assessing the consistency of fresh concrete. The test primarily measures a mix’s response to gravity, which is predominantly a function of its yield stress. The resulting slump value provides no information about the plastic viscosity of the mix. This deficiency means that a single slump value cannot reliably predict a mix’s behavior during pumping, placing, and finishing, which are highly dependent on plastic viscosity. For advanced materials like SCC, which are designed to flow under their own weight, a different metric, the slump flow test, is used, but it still measures an empirical value that is not a true rheological property. The inadequacies of these traditional, single-point tests highlight the need for a more scientific approach.

2.2 Advancements in Rheological Measurement

To overcome the shortcomings of empirical tests, modern rheological analysis employs sophisticated devices to quantify both yield stress and plastic viscosity.

-

Rotational Rheometers: These devices are the standard for laboratory research, providing a full flow curve by applying continuous shear to a concrete sample and measuring the resulting torque. They operate on various geometries, including coaxial cylinders, vanes, and helical impellers.

2.3 Real-Time Viscosity Control During Mixing

The ultimate goal of viscosity management is to transition from a reactive, off-line process to a proactive, real-time control system. Off-line lab tests are of limited value for process control because concrete properties change over time due to hydration, temperature, and shear history. In-line, real-time monitoring is the only way to ensure batch-to-batch consistency in a dynamic production environment.

-

Torque-Based Systems: A direct and practical method for real-time monitoring involves measuring the torque on the mixer motor or shaft. The torque required to rotate the mixer is directly proportional to the viscosity of the mix. A sharp increase in torque indicates the addition of a new load, and a drop-off signifies that the mix is becoming more consistent. This allows operators to make on-the-spot adjustments to reach the desired consistency in the shortest time.

-

Emerging Technologies: Advanced technologies Lonnmeter viscometers provide continuous, non-contact measurements directly within the mixer or in-line. They track key parameters in real-time, eliminating the need for manual sampling and providing drivers and quality control personnel with immediate feedback for on-the-go adjustments.

The advent of automated, in-line viscosity measurement enables a fundamental shift from a reactive to a proactive quality management paradigm. In a traditional workflow, a mix is batched, and a sample is taken for a slump test. If the mix is off-spec, the batch is either adjusted or rejected, leading to wasted time, energy, and material. With a real-time, in-line system, a continuous stream of data on the mix’s consistency can be fed back into an automated dosing system. This creates a closed-loop control system that automatically guides the mix to the desired rheological endpoint, ensuring every batch meets specifications and virtually eliminating the risk of human error or rejected loads. This sophisticated feedback mechanism is a crucial enabler of both quality and profitability.

2.4 The Influence of Mixing Parameters

Mixing is not merely a process of blending ingredients; it is a critical stage that fundamentally shapes the rheology and microstructure of the fresh mix.

-

Mixing Time and Energy: The duration and intensity of mixing have a significant impact on rheological properties. Under-mixing leads to non-homogeneity, which compromises both fresh and hardened concrete properties. Over-mixing is a waste of energy and can be detrimental to the final product. Low water-binder ratio concrete, in particular, requires a longer mixing time and higher energy to achieve homogeneity.

-

Mixing Sequence: The order in which materials are added to the mixer can also affect the final rheology. For some mixers, adding fine materials first can cause them to stick to blades or confine in corners, negatively impacting the uniformity of the mix. The proper sequence is particularly important for low W/Cm mixes, which are more sensitive to variations.

3. Viscosity’s Influence on Fresh Concrete Performance

Viscosity management is not an abstract exercise; it is the direct means of controlling the workability and stability of fresh concrete, ensuring it behaves predictably during placement and consolidation.

3.1 The Viscosity-Workability Relationship

Workability is a broad term encompassing the ease with which a mix can be handled, placed, and finished. It is a delicate balance between flow and stability, and it is entirely governed by a mix’s rheological profile.

-

Pumpability: The ability to pump concrete over long distances or to great heights is primarily a function of plastic viscosity. High-viscosity concrete requires significantly higher pumping pressures to overcome friction loss, while a low plastic viscosity and yield stress are required for smooth, efficient flow.

-

Placeability and Consolidation: Proper viscosity ensures that a mix can be placed easily, flow into intricate formwork, and encapsulate reinforcement without voids. Viscosity-modifying admixtures can increase lubricity, reducing the energy needed for consolidation and ensuring a uniform mix is achieved with less effort.

3.2 Ensuring Homogeneity and Stability

The homogeneity of fresh concrete is a critical factor for final product quality. Without a cohesive mix, concrete is prone to two primary forms of separation: bleeding and segregation. Viscosity is the key property for mitigating these phenomena.

-

Bleeding: A form of segregation on the micro-level, bleeding occurs when water rises to the surface of the fresh mix because the solids cannot hold all the mixing water. This is caused by density differences and the self-weight consolidation of the solid particles.

-

Segregation: This is the separation of coarse aggregates from the mortar. When the viscosity of the cement paste is insufficient, aggregates, which are denser than the paste, will settle to the bottom of the formwork.

The rheological parameters govern these phenomena in different ways. Yield stress is the primary control for static segregation, which occurs when the mix is at rest. A high enough yield stress prevents particles from settling under their own weight. Plastic viscosity, on the other hand, is the key control for dynamic segregation, which occurs during flow or vibration. A higher plastic viscosity provides the cohesive resistance needed to prevent heavier particles from moving relative to the paste.

Achieving a highly flowable mix while preventing segregation is a delicate balancing act. For materials like self-consolidating concrete, the mix must have a low enough yield stress to flow under its own weight but a high enough plastic viscosity to resist dynamic segregation during placement and still have a high enough yield stress to resist static segregation after placement. This simultaneous requirement is a complex optimization problem that relies heavily on a precise understanding of rheology and the use of strategic admixtures like VMAs to provide the necessary cohesion.

3.3 Achieving a Superior Finish

Proper viscosity management is a prerequisite for a high-quality, durable surface finish.

-

Surface Appearance: A well-managed viscosity prevents excess bleeding, which can create a weak, watery layer (laitance) on the surface that compromises durability and aesthetics.

-

Air Bubble Escape: An adequate plastic viscosity is required to allow entrapped air bubbles to escape during consolidation, preventing voids and ensuring a smooth, dense surface. A viscosity that is too high, however, will trap air bubbles, leading to defects like honeycombing.

Table 2: Viscosity’s Impact on Fresh Concrete Properties

|

Fresh Concrete Property |

Governing Rheological Parameter(s) |

Desired State |

Rationale |

|

Pumpability |

Plastic Viscosity & Yield Stress |

Low |

Lower plastic viscosity and yield stress reduce friction loss and pumping pressure. |

|

Static Segregation Resistance |

Yield Stress |

High |

A high enough yield stress prevents particles from settling under their own weight at rest. |

|

Dynamic Segregation Resistance |

Plastic Viscosity |

High |

High plastic viscosity provides cohesive resistance to particle movement during flow. |

|

Finishability |

Plastic Viscosity |

Adequate |

Not too low (causes bleeding) and not too high (traps air), ensuring a smooth, durable surface. |

|

Placeability |

Yield Stress & Plastic Viscosity |

Low |

A low yield stress and plastic viscosity enable the mix to flow and fill complex forms and reinforcement cages. |

4. The Causal Link: From Viscosity to Final Product Quality

The control of fresh concrete properties through viscosity management is not an end in itself; it is the necessary precondition for achieving the designed strength, durability, and reliability of the final, hardened product.

4.1 The Homogeneity-Strength Connection

The properties of fresh concrete directly affect the quality and strength of the hardened concrete. The technological control of hardened concrete properties, such as compressive strength, is meaningless without first controlling the fresh state. The theoretical strength of a concrete mix is largely determined by its water-cement ratio. However, the actual, realized strength of a structure is highly dependent on how uniformly the materials are distributed within the mix.

In a fresh mix, if the viscosity is too low, heavier aggregates will settle, and water will bleed to the surface.

This creates zones with varying W/Cm ratios: a higher ratio in the upper layers (from bleeding) and a lower ratio in the bottom layers (from aggregate settlement). As a result, the hardened concrete will not be a homogeneous material with uniform strength. The upper layers, with their higher porosity from bleeding, will be weaker and more permeable, while the lower layers may contain voids and honeycombing from poor consolidation and segregation. Managing viscosity in the fresh state is akin to “locking in” the strength potential of a given mix design by ensuring homogeneity and preventing these defects from forming. It is a necessary prerequisite for achieving the designed strength and durability.

4.2 Voids, Density, and Durability

Effective viscosity management is a primary preventative measure against common defects that compromise the long-term durability of a structure.

-

Mitigating Honeycombing and Voids: A mix with a balanced rheological profile—sufficiently flowable to fill forms but with a low enough viscosity to allow entrapped air to escape—is a key defense against honeycombing and voids. These defects not only affect a structure’s aesthetics but also seriously compromise its structural integrity by creating weak spots that can accumulate moisture.

-

Porosity and Permeability: Bleeding and segregation create channels and voids within the concrete matrix, which significantly increase its porosity and permeability. Increased permeability allows for the ingress of water, chlorides, and other deleterious ions, which can lead to corrosion of reinforcing steel and freeze-thaw damage. The use of viscosity-modifying admixtures has been shown to reduce these long-term transport coefficients by increasing the viscosity of the pore solution in the hardened concrete.

5. Economic and Practical Benefits

Precise viscosity management is a strategic lever that directly impacts a concrete producer’s bottom line by reducing waste, increasing efficiency, and lowering overall costs.

5.1 Quantifiable Cost Reduction

-

Reduced Waste and Rejects: Real-time viscosity monitoring enables producers to accurately and reliably identify the “end point” of the mixing process, preventing over-mixing and ensuring that every batch meets specifications. This significantly reduces material waste and the number of rejected loads, which are a major source of cost and liability.

-

Energy and Time Savings: Optimizing the mixing process through viscosity control saves both time and energy. Real-time data can prevent over-mixing, which is a waste of both time and electricity, and it can detect under-mixing, preventing the need for costly rework.

5.2 Maximizing Operational Efficiency

-

Streamlined Production: Automated, real-time viscosity monitoring streamlines the entire production process, reducing the need for time-consuming manual sampling and testing. This allows quality control personnel to manage their teams and workloads more effectively, even from remote locations.

-

Lower Labor Requirements: The use of rheology-controlled mixes, particularly SCC, can significantly reduce or eliminate the need for manual vibration and consolidation. This translates into smaller placement crews, which leads to significant labor cost savings.

-

Fewer Customer Complaints and Liabilities: Producing consistent, high-quality concrete batches reduces customer complaints and minimizes the risk of costly liabilities and litigation resulting from structural defects or failures.

5.3 Material Cost and Performance

-

Cost-Effective Alternatives: Studies have shown that using mineral admixtures like fly ash or slag cement as partial replacements for cement can achieve the desired rheological properties while being significantly more economical (30-40% cost savings in some cases).

-

Strategic VMA Use: While commercial viscosity-modifying admixtures can be costly, the development of new, more economical admixtures and the ability to use them in precise dosages based on real-time data allows for cost-effective performance gains.

6. Actionable Recommendations for Industry Implementation

For concrete producers and construction companies to fully realize the benefits of viscosity management, a strategic shift in both approach and technology is required.

6.1 Mix Design Adjustments for Viscosity Control

The goal of mix design is to balance strength, durability, and workability. By actively controlling the following parameters, producers can proactively manage viscosity.

-

Control the Water-Cement Ratio: The W/Cm ratio is the primary determinant of strength and sets the baseline for the mix’s viscosity. A target W/Cm of 0.45-0.6 is often considered ideal for general workability, but this can be lowered for high-strength applications with the use of water-reducing admixtures.

-

Optimize Aggregate Gradation: Utilize well-graded aggregates to minimize the paste requirement and improve workability. Routinely test aggregates for moisture content, fineness, and shape to ensure consistency from batch to batch.

-

Strategic Use of Fines: Increase the fines content (e.g., with fly ash, slag cement, or silica fume) to improve flowability and stability without adding extra water. The spherical shape of fly ash particles, in particular, enhances lubricity and can reduce the need for more costly VMAs.

Table 3: Practical Mix Design Adjustments for Rheology Control

|

Component |

Impact on Viscosity |

Practical Adjustment for Desired Result |

|

Water |

Decreases viscosity. |

Add water to increase workability, but only as a last resort due to strength trade-offs. |

|

Aggregates (Size/Shape) |

Increases viscosity. |

Use well-graded aggregates to minimize paste demand and manage shape (crushed for bond, but not excessively angular). |

|

Fines Content |

Decreases viscosity. |

Increase fine content (e.g., with fly ash or slag) to improve flowability and cohesion. |

|

Superplasticizers |

Decreases viscosity. |

Use to achieve high workability and flow at a low W/Cm ratio. |

|

Viscosity Modifiers (VMAs) |

Increases viscosity. |

Employ to improve cohesion and segregation resistance without sacrificing flowability. |

6.2 Strategic Use of Admixtures

Admixtures are the primary tools for fine-tuning concrete rheology and should be used strategically to meet specific performance goals.

-

Superplasticizers: For mixes where high flowability and strength are required, use high-range water reducers to achieve the desired workability at a low W/Cm ratio.

-

Viscosity Modifying Admixtures (VMAs): Employ VMAs for mixes requiring high segregation resistance, such as SCC, underwater concrete, and high-rise vertical pours. They are essential for providing cohesion and for mitigating the effects of harsh or gap-graded aggregates.

-

Trial Mixes are Crucial: The performance of admixtures can be affected by temperature and other mix components. Always perform trial mixes to determine the optimal dosages for specific site conditions.

6.3 A Modern Quality Control Framework

The shift from a reactive to a proactive quality control framework is the final step in a successful viscosity management strategy.

-

Shift from Slump to Rheology: For modern mixes, move beyond the slump test to incorporate more sophisticated rheological assessments, such as rotational rheometers in the lab or modified slump tests in the field that measure both slump height and slump flow time.

-

Embrace In-Line Monitoring: Invest in real-time, in-line viscosity and torque sensors to monitor mix consistency. This is the most effective way to ensure product uniformity, reduce waste, and optimize production efficiency.

-

Develop Comprehensive QC Checklists: Establish standards that go beyond traditional slump and strength tests. Monitor key parameters such as aggregate moisture content, mix temperature, and mixing time as part of a holistic quality control protocol.

Viscosity management is no longer an ancillary concern; it is a core competency for modern concrete producers and construction companies. The transition from traditional, empirical methods to a scientific, rheology-based approach provides a clear path for innovation, efficiency, and a new standard of quality in the concrete industry. By leveraging real-time data, understanding the intricate interplay of mix components, and implementing a robust quality control framework, companies can ensure a homogeneous, defect-free fresh concrete mix. This proactive control serves as the essential precondition for achieving the designed strength and durability of the hardened product. In doing so, it allows for greater profitability and predictability, ultimately providing a competitive advantage in a demanding and evolving market.

Post time: Sep-01-2025