Inline density meters deliver continuous data essential for acetophenone purification in perfume fixative applications. Real-time measurement enables precise detection of benzene and acetyl chloride impurities below 0.5%, directly supporting acetophenone purity standards for fragrance manufacturing. Density feedback allows automated adjustment of distillation reflux ratios in the 2:1–3:1 range, ensuring 99.5% acetophenone content through controlled precision distillation techniques.

Stabilizing organic phase density between 1.045–1.050 g/cm³ during oxime synthesis via dichloromethane extraction prevents formation of oxime hydrolysate, optimizing sodium hydroxide dosage for reaction endpoint detection. Inline instruments such as Lonnmeter inline density meters and concentration meters promptly flag incomplete extraction and enable exact extractant flow rate optimization, reducing raw material loss and minimizing rework.

Direct integration of inline measurement automates product diversion when density exceeds 1.027 g/cm³ and eliminates manual sampling, supporting continuous blending and compounding of high-purity acetophenone with documented proof for compliance.

Acetophenone Fixative Production

*

Inline density meters deliver essential process intelligence for acetophenone purification in perfume fixative applications. Real-time density measurement enables strict adherence to acetophenone purity standards, supporting continuous detection of benzene and acetyl chloride impurities below 0.5%. Operators optimize precision distillation techniques and automatically adjust reflux ratios to maintain 99.5% acetophenone. During blending and compounding in fragrance manufacturing, inline density meters confirm organic phase density stabilization to 1.045–1.050 g/cm³, preventing oxime hydrolysate formation through early reaction endpoint detection.

Acetophenone Production Process Overview

Ethylbenzene oxidation produces acetophenone, catalyzed by cobalt or manganese acetates at 120–200°C for yields up to 90%. Multi-stage separation eliminates phenylethane and hydroperoxides, then precision fractional distillation isolates acetophenone. Inline density meters monitor distillate purity, enabling real-time reflux ratio adjustment to sustain ≥99.5% acetophenone, critical for perfume fixative applications. Density feedback facilitates benzene and acetyl chloride impurity detection—maintaining sub-0.5% thresholds is essential for acetophenone purification. Automated inline control ensures distillation reflux ratios between 2:1 and 3:1, improving impurity removal and reducing manual errors.

During oximation, dichloromethane extraction stabilizes organic phase density between 1.045–1.050 g/cm³, directly monitored using Lonnmeter inline density instruments. This density window prevents formation of oxime hydrolysate and controls sodium hydroxide addition. Density drops indicate incomplete extraction, triggering precise extractant flow rate optimization for high-purity acetophenone production. Inline measurement drives blending and compounding accuracy, supporting acetophenone purity standards and efficient fragrance manufacturing.

Fragrance Fixatives

*

Challenges in Inline Density Measurement

Inline density measurement for acetophenone purification faces significant technical and operational challenges:

Detection of benzene and acetyl chloride impurities below 0.5% is required to meet acetophenone purity standards for perfume fixative applications. Density deviations as low as 0.0005 g/cm³ must be monitored to enable rapid impurity removal methods and immediate corrections.

Precision distillation techniques use real-time density feedback to maintain a controlled reflux ratio (2:1–3:1). Tight density control prevents product off-spec and raw material loss. Fluctuations indicate variation in acetophenone purity or incomplete blending and compounding in fragrance manufacturing.

The oximation reaction process demands exact determination of the endpoint. Inline instruments must detect a density growth rate of ≤0.001 g/cm³/h for safe and automated alkali addition control, preventing excess sodium hydroxide in organic synthesis.

Incomplete dichloromethane extraction appears as a density drop in the organic phase. Lonnmeter inline density meters enable extractant flow rate optimization, ensuring phase density stabilizes at 1.045–1.050 g/cm³ during acetophenone oxime synthesis monitoring.

Effective oxime hydrolysate prevention depends on real-time reaction endpoint detection in chemical processes. Inline measurement signals when to stop alkali feed before byproducts form.

Benefits of Integrating Inline Density Meters

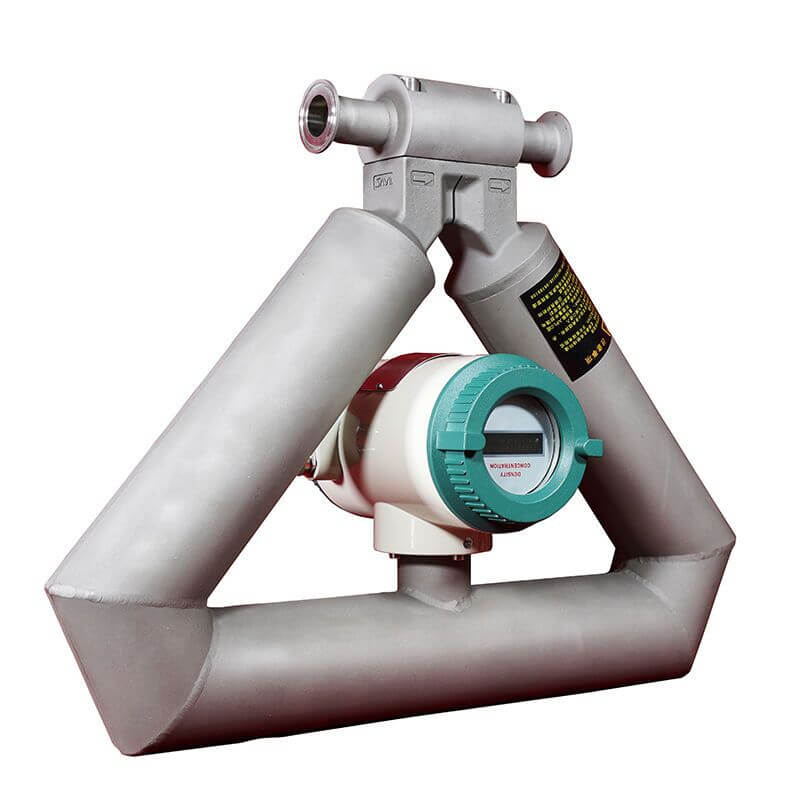

Automated product valve control tied to inline density measurement ensures outflow only occurs above 1.027 g/cm³, sharply reducing sub-spec material release. Continuous density monitoring enables instant detection of benzene and acetyl chloride impurities below 0.5%, triggering immediate operational correction. Real-time feedback optimizes distillation reflux ratios between 2:1 and 3:1, increasing acetophenone yield above 99.5% while lowering raw material waste. Inline analysis eliminates manual sampling, cutting sample wait times and human error, and reduces average downtime for quality verification by over 40%. Consistent inline data stabilizes blending and compounding, maintaining acetophenone purity for perfume fixative applications across long runs. Every density value and adjustment is logged, providing auditable documentation for compliance with acetophenone purity standards. Lonnmeter instruments support seamless integration into existing process lines, delivering precise control during distillation, extraction, and oximation with minimal intervention.

Solve Tricky Problems in Production Process

Request a quote for Lonnmeter inline density meter to address acetophenone purification and perfume fixative applications. Utilize Lonnmeter instruments for inline density measurement advantages, distillation reflux ratio optimization, and dichloromethane extraction process reliability. Support acetophenone purity standards documentation, immediate process correction, and extractant flow rate optimization with robust, direct process sensors.

Post time: Jan-28-2026