The chlorine alkali electrolysis is carried out in two processes: the diaphragm and the membrane process, in which brine concentration monitoring is critical for optimizing processes. Brines, often containing high levels of sodium chloride (NaCl) and other ions, are processed through techniques like brine purification electrodialysis and chlorine alkali electrolysis.

Challenges like inconsistent measurements, sensor fouling, and high energy consumption can hinder efficiency. Moreover, life of the membrane will be affected for mechanical impurities and calcium or magnesium salts, which clog the fine pores of the diaphragma or membrane during the electrolysis.

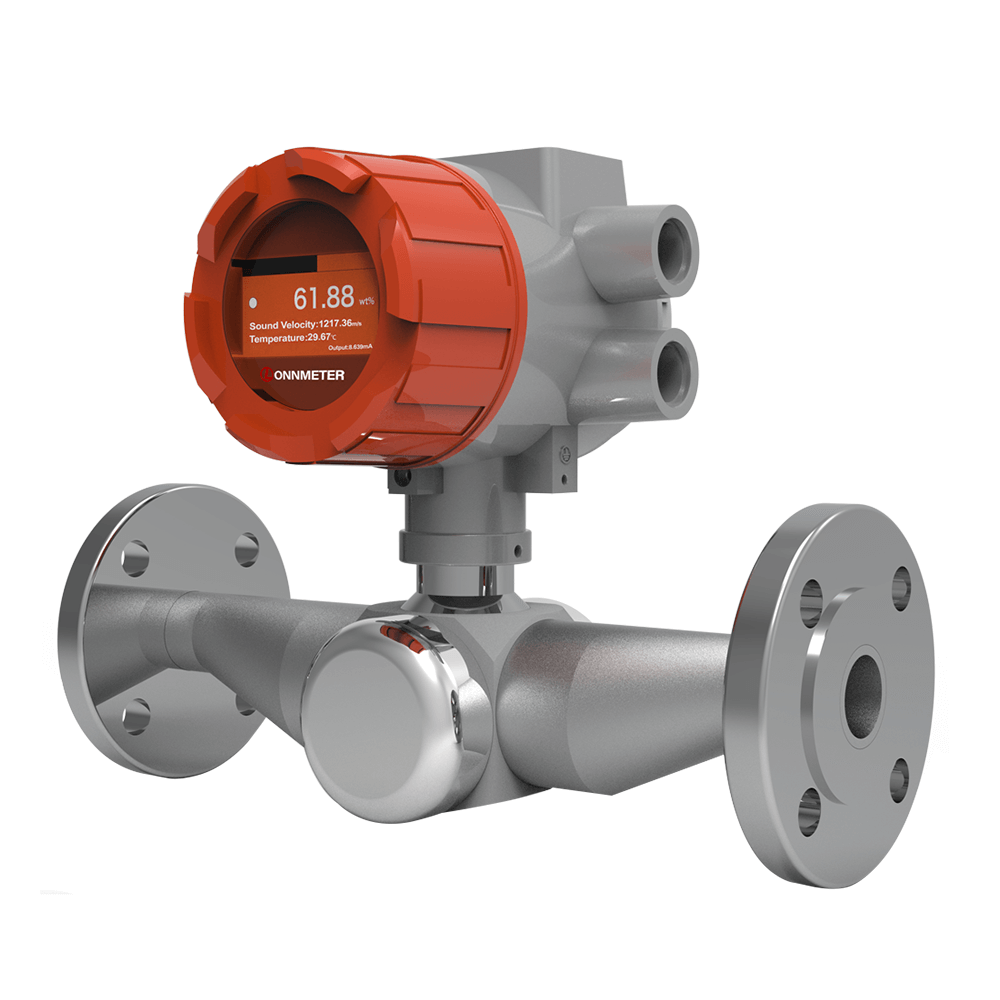

Lonnmeter, an experienced solution provider and the leading manufacturer of inline concentration meter, offer numerous solutions to process engineers, operations managers, and quality control professionals who are seeking reliable brine concentration sensors and instruments used to determine brine concentration to address these issues. Read on to discover how advanced monitoring systems can transform your operations.

Understanding Brine Purification and Concentration Challenges

What is Brine Purification?

Brine purification is the process of treating saline solutions to remove impurities, such as divalent ions (Ca²⁺, Mg²⁺), organic matter, and scaling compounds like calcium sulfate (CaSO₄). It is a critical procedure in industries like chlor alkali brine purification and sodium chloride brine purification, where high-purity brine is essential for efficient chloralkali process. Technologies like electrodialysis (ED) and electrodialysis reversal (EDR) are widely used to concentrate brine while separating target ions. However, accurate brine concentration control in chlor alkali processes is vital to avoid inefficiencies, such as increased energy consumption or compromised product quality.

Pain Points in Brine Concentration Measurement

Complex Brine Composition Interference

Brines from seawater reverse osmosis or industrial processes often contain a mix of monovalent (Na⁺, Cl⁻) and divalent ions (Ca²⁺, Mg²⁺, SO₄²⁻), along with organic matter and scaling compounds like silica. These components interfere with brine concentration sensors, leading to inaccurate readings. For instance, conductivity probes, commonly used for brine concentration measurement, may misinterpret signals due to divalent ions or organic fouling, complicating real-time monitoring in brine purification electrodialysis.

Fouling and Scaling on Sensors

High-salinity brines, often reaching 180–200 g/L total dissolved solids, cause fouling and scaling on brine concentration monitors like conductivity probes or ion-selective electrodes. Scaling compounds like calcium carbonate or sulfate build up on sensor surfaces, reducing accuracy and requiring frequent maintenance. In chlor alkali brine purification, this leads to increased downtime and costs, even with electrodialysis reversal mitigating membrane fouling.

Concentration Polarization Effects

In brine purification electrodialysis, concentration polarization near ion-exchange membranes creates local ion concentration variations, making it difficult to measure true bulk brine concentration. This is especially problematic at high current densities, where ion migration amplifies polarization, leading to fluctuating readings from instruments used to determine brine concentration.

Solutions for Effective Brine Concentration Monitoring

Introducing Brine Concentration Monitor to Production Line

Advanced brine concentration monitors brine concentration in time to prevent fouling in advance. Then minimize scaling from calcium sulfate or carbonate, reducing maintenance frequency in brine purification processes. Lonnmeter ultrasonic concentration meter is appliable to real-time concentration measurement in brine purification electrodialysis.

It infers the speed of sound by measuring the transmission time of sound wave from the signal source to the signal receiver. This measurement method is not affected by the conductivity, color and transparency of the liquid, ensuring extremely high reliability. Users can achieve a measurement accuracy of 5‰, 1‰, 0.5‰.

In-Line Pretreatment Systems

Implementing in-line pretreatment to remove scaling compounds (e.g., CaSO₄, silica) before brine purification electrodialysis reduces sensor fouling and improves measurement accuracy. Pretreatment systems, such as nanofiltration or chemical precipitation, ensure cleaner brine enters the ED process, benefiting both sensors and membranes.

Intelligent Monitoring Systems

Combining real-time brine concentration sensors with periodic offline analysis balances cost and accuracy. While advanced methods like ICP-OES are impractical for continuous monitoring, they provide high-precision data for calibration, ensuring reliable brine concentration control in chlor alkali processes.

Advanced Process Control with Analytics

Real-time data analytics and machine learning can correct for concentration polarization effects and improve measurement reliability. By analyzing sensor data alongside process parameters, these systems optimize brine concentration monitoring without additional hardware, reducing energy consumption and costs.

FAQs

What is Brine Purification?

Brine purification involves removing impurities from saline solutions to produce high-purity brine for industrial applications like chlor alkali brine purification or brine purification electrodialysis. It ensures efficient processes and high-quality outputs by using technologies like ED to concentrate and purify brine.

What Instruments Are Used to Determine Brine Concentration?

Common instruments used to determine brine concentration include conductivity probes, ion-selective electrodes, and advanced analytical tools like ion chromatography. Conductivity probes are cost-effective but less selective, while ion-selective electrodes offer precision for specific ions in brine concentration measurement.

How Can I Address Brine Concentration Problems?

Brine concentration problems like fouling, polarization, or interference can be addressed with the ultrasonic concentration sensor, in-line pretreatment, and electrodialysis reversal. Hybrid monitoring systems and advanced analytics further enhance accuracy and efficiency in brine purification processes.

Effective brine concentration monitoring is essential for optimizing brine purification in desalination, chlor-alkali, and wastewater treatment industries. By addressing pain points like complex brine compositions, sensor fouling, and concentration polarization effects, advanced brine concentration sensors and process optimization strategies can significantly improve efficiency and reduce costs.

Contact the trusted supplier Lonnmeter of brine concentration monitors today to request a quote or demo and take control of your operations.

Post time: Jun-18-2025