In potassium chloride (KCL) production, achieving optimal flotation performance is critical for maximizing recovery and ensuring high-purity output. Unstable slurry density can lead to reagent inefficiencies, reduced yields, and increased costs.

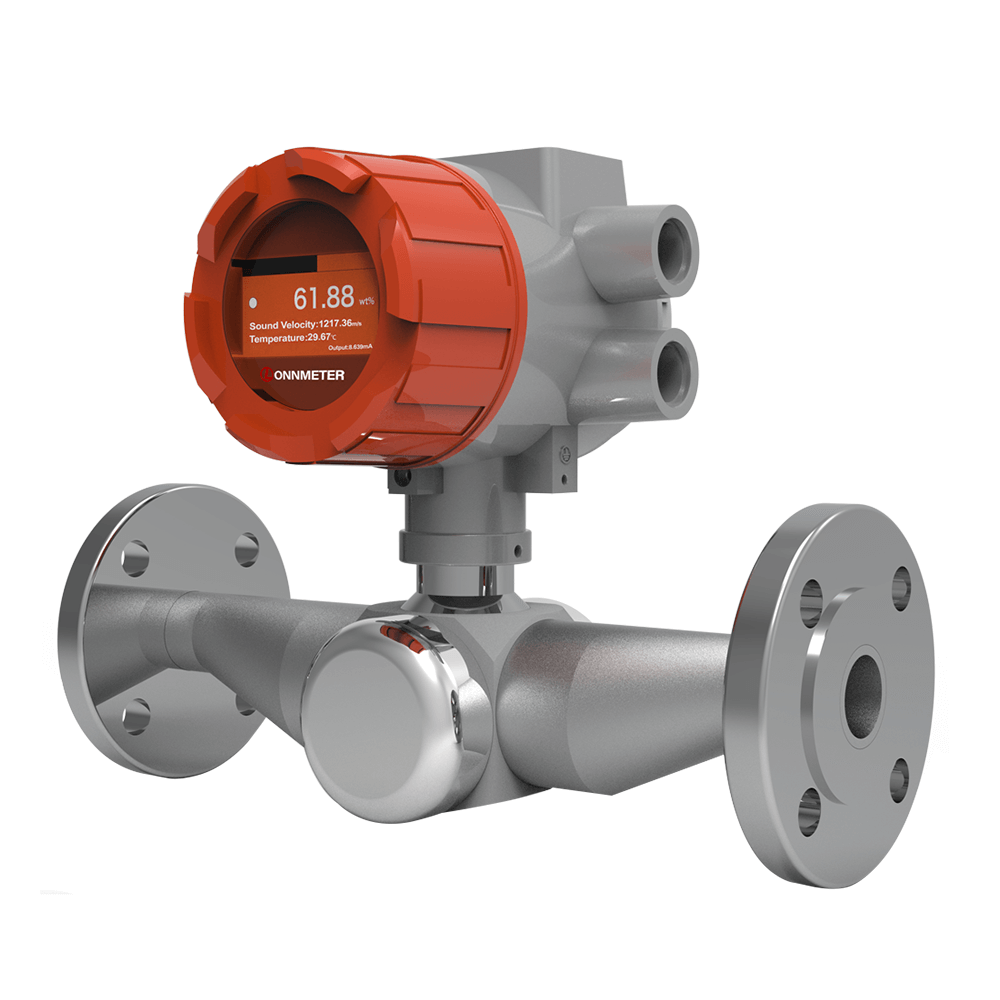

Lonnmeter’s Ultrasonic Concentration Meter, an advanced inline KCL density meter, harnesses cutting-edge ultrasonic sound velocity technology to deliver precise, real-time KCL density measurement. Engineered for the demanding conditions of KCL plants, this robust solution offers drift-free accuracy, optional titanium construction, and seamless integration with automation systems. Ready to transform your KCL production? Discover how Lonnmeter’s KCL density meter online empowers producers to optimize processes, boost profitability, and achieve unparalleled product quality.

Why KCL Density Measurement Matters in Flotation

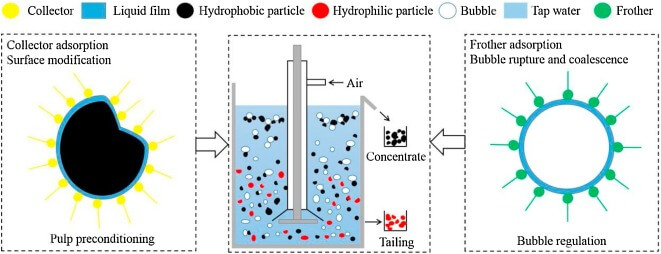

KCL flotation is a delicate process where crude salt (KCl and NaCl) is mixed with saturated mother liquor, ground to ~1mm crystal size, and processed in flotation cells. Surface-active reagents coat KCL crystals, enabling air bubbles to form a KCL-rich foam, while NaCl sediments for further processing. Accurate KCL density measurement ensures optimal slurry concentration, which is pivotal for reagent efficiency, foam stability, and effective separation.

Compromised Reagent Efficiency: High slurry densities (>1.3 g/cm³) increases viscosity, hindering amine dispersion and reducing bubble attachment efficiency by 10-15%, lowering KCL recovery to 80-85%. Low density (<1.1 g/cm³) dilutes reagents, increasing amine consumption by 20-30% and risking KCL loss in tailings (up to 5% KCl content).

Foam Instability: Excessive density creates viscous “dead foam” with low froth mobility, entraining impurities like NaCl or MgSO₄ (up to 5-7% contamination), reducing KCL purity to <95%. Low density produces thin, unstable foam, allowing fine KCL particles (<0.1mm) to escape, cutting yields by 5-10%.

Equipment Stress: High-density slurries increase shear forces on flotation cell impellers, reducing lifespan by 20-30% (e.g., 6-9 months vs. 12 months). Low-density slurries elevate water usage in dewatering (e.g., 1.5-2 m³/ton KCl), raising energy costs by 15-25% during centrifugation.

Process Variability: Manual density sampling, with 10-30 minute delays, causes fluctuations (±0.05 g/cm³), disrupting froth stability and recovery consistency, increasing operator workload by 25%.

Benefits of Inline KCL Density Meter for KCL Producers

Lonnmeter’s KCL density meter inline revolutionizes KCL production by offering precise, drift-free measurements and robust construction, including optional titanium components for durability. This technology empowers KCL factories to optimize flotation, reduce operational costs, and achieve consistent product quality, addressing the pain points of unstable processes and high maintenance.

Key Advantages of Lonnmeter Inline Concentration Meter

Real-Time Process Control: The KCL density meter online detects density changes within seconds, enabling rapid adjustments to slurry feed, water, or reagents. This ensures stable flotation conditions and maximizes KCL recovery.

Cost Efficiency: By maintaining optimal slurry density, the meter minimizes reagent overuse (e.g., collectors and frothers) and reduces energy consumption in dewatering, lowering production costs significantly.

Superior Product Quality: Precise density control prevents impurity carryover, ensuring high-purity KCL output that meets stringent market standards.

Long-Term Reliability: Drift-free sensors and durable materials reduce maintenance needs, offering years of consistent performance even in harsh environments.

Automation Integration: Seamlessly integrates with advanced control systems (e.g., model predictive control) to dynamically adjust parameters like slurry flow and reagent dosing, enhancing process stability.

Early Malfunction Detection: Identifies issues like equipment blockages or reagent imbalances in seconds, preventing costly downtime and production losses.

Sustainability Benefits: Reduces water, energy, and material waste, supporting environmentally responsible production practices.

|

Feature |

Lonnmeter Inline Meter |

Traditional Methods |

|

Response Time |

<5 seconds |

10-30 minutes |

|

Accuracy |

±5‰; 1‰;0.5‰ |

±1% |

|

Maintenance Frequency |

1x per year |

3-4x per year |

|

Durability |

Titanium construction, drift-free |

Prone to corrosion, frequent drift |

|

Automation Integration |

Seamless (4-20 mA, RS485, Modbus) |

Limited or manual integration |

|

Cost Efficiency |

Saves $50,000-$100,000/year (mid-sized plant) |

Higher reagent/energy costs (15-25% more) |

|

Real-Time Monitoring |

Continuous, real-time data |

Periodic, delayed readings |

|

Operational Downtime |

Minimal (<5s issue detection) |

Significant ($10,000+/h potential loss) |

FAQs

How does an inline KCL density meter improve flotation efficiency?

An inline KCL density meter provides real-time KCL density measurement, ensuring optimal slurry density for effective reagent use and stable foam formation. This boosts KCL recovery rates and reduces operational costs.

Is Lonnmeter’s KCL density meter suitable for demanding production environments?

Yes, Lonnmeter’s KCL density meter inline features robust construction with optional titanium components, ensuring durability, minimal maintenance, and reliable performance in harsh KCL production settings.

Mastering KCL density measurement is essential for optimizing flotation and achieving high-quality potassium chloride output. Lonnmeter’s inline KCL density meter delivers real-time precision, cost savings, and process stability, empowering KCL producers to overcome concentration challenges. Don’t let inefficiencies impact your bottom line. Click now to claim one of 1,000 free samples or download our exclusive KCL flotation industry report to unlock the full potential of your production line. Act fast—custom OEM/ODM solutions and priority access to cutting-edge technology are available!

Post time: Jun-10-2025