Effective water treatment hinges on the preparation and dosing of polyelectrolytes. These polymers facilitate the aggregation of suspended solids, enabling efficient removal of impurities from wastewater and potable water. However, improper viscosity or concentration of polyelectrolyte solutions can lead to inadequate floc formation, clogged systems, or non-compliance with stringent environmental regulations, resulting in costly penalties and environmental harm.

Water treatment plants can achieve precise control over polyelectrolyte dosing by utilizing automated inline monitoring. Lonnmeter’s advanced viscosity measurement solutions empower treatment facilities to meet regulatory standards, minimize costs, and contribute to sustainable water management.

Coagulation and Flocculation Process in Water Treatment

The coagulation process in water treatment aims at removing suspended solids, colloids, and organic matter from water and wastewater. This process involves two key stages: coagulation, where destabilizing agents neutralize particle charges, and flocculation, where particles aggregate into larger, settleable flocs.

The coagulation flocculation process is vital for applications like raw water clarification, color removal, and sludge dewatering across industries such as power, steel, mining, food, textiles, and pulp and paper. Proper mixing intensity is critical, as fractal analysis indicates that diffusion and collision of colloidal particles govern floc formation.

The Role of Polyelectrolytes in Water Treatment

Polyelectrolytes are indispensable in the coagulation of water treatment processes, acting as flocculation agents that enhance particle aggregation. These long-chain organic polymers, available in cationic, anionic, or non-ionic forms, carry ionizable functional groups that promote floc formation through charge neutralization and bridging. In wastewater treatment, polyelectrolytes are used for clarification, sludge conditioning, and de-oiling, while in industrial applications, they improve processes like gypsum separation in phosphoric acid production or clay removal in borax streams.

Consequences of Incorrect Concentration & Viscosity of Wastewater

Incorrect polyelectrolyte concentration or viscosity in the coagulation process in wastewater treatment can have severe repercussions, jeopardizing the delicate balance of water treatment systems.

Overdosing can cause particle resuspension, clogging treatment facilities or leading to frozen pipes and bursts, while underdosing results in poor floc formation, leaving water turbid and non-compliant with discharge standards. Such failures can incur hefty fines from regulatory bodies, damage equipment, and release improperly treated water into rivers or oceans, harming ecosystems.

Polyelectrolytes - The Flocculation Agents

As key flocculation agents, polyelectrolytes drive the coagulation flocculation process by promoting the aggregation of fine particles into larger flocs that can be easily separated through sedimentation or flotation. Available in various forms—granular, powder, or highly viscous liquids (5,000–10,000 cP)—polyelectrolytes like polyacrylamide (PAAM) are tailored for specific applications based on charge, molecular weight, and morphology.

In wastewater treatment, they facilitate the removal of suspended solids, color, and oils, while in industrial processes, they enhance operations like sugar juice clarification and metal deposition in electrolytic refining. However, polyelectrolytes have a narrow flocculation window, where slight overdosing can redisperse particles, and degradation over time reduces viscosity, impacting performance. Precise dosing and real-time monitoring are essential to maximize their efficacy in the coagulation of water treatment processes.

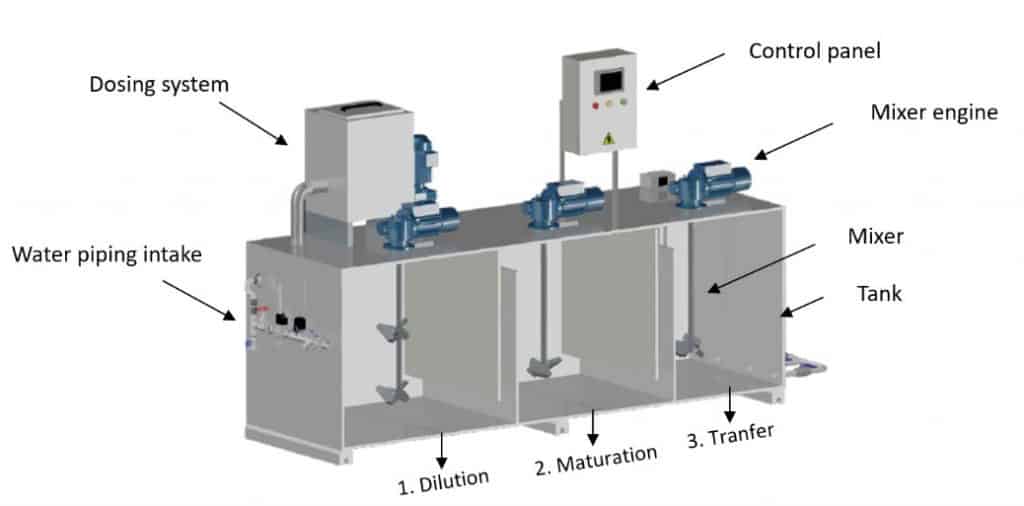

Automatic preparation unit (Ref: Keiken Engineering)

Necessities of Automated Preparation & Dosing System

Automated preparation and dosing systems are transforming the coagulation and flocculation process in water treatment by ensuring accuracy and efficiency in polyelectrolyte application. These systems address critical needs in modern treatment plants, enhancing performance and compliance.

I. Ensure Correct Concentration of Polyelectrolyte Solutions

- Precision Dosing: Automated systems deliver polyelectrolyte concentrations (e.g., 0.2–1 g/L for sludge treatment, 0.02–0.1 g/L for clarification) to optimize floc formation.

- Regulatory Compliance: Accurate dosing prevents overdosing or underdosing, ensuring compliance with environmental discharge standards.

- Reduced Waste: Precise concentration minimizes chemical overuse, lowering costs and environmental impact.

- Process Stability: Maintains consistent floc quality, reducing risks of system blockages or equipment damage.

II. Concentration Dependence of Viscosity

- Viscosity as a Performance Indicator: Polyelectrolyte viscosity correlates with molecular weight and chain integrity, directly affecting flocculation efficiency.

- Real-Time Adjustments: Automated systems monitor viscosity changes due to degradation or dilution, ensuring optimal dosing.

- Two-Stage Mixing: High-energy initial mixing prevents “fisheye” formation, while low-energy mixing preserves polymer chains, maintaining viscosity.

- Application-Specific Dosing: Adjusts viscosity for specific tasks like sludge dewatering or raw water clarification, enhancing process flexibility.

Product Solution: Online Polymer Viscometer

Lonnmeter’s online viscometer polymer is a game-changer for coagulation process in wastewater treatment, offering real-time viscosity monitoring to optimize polyelectrolyte dosing. Key features include:

- Wide Viscosity Range: Measures 10–1,000,000 cP, accommodating high-viscosity emulsion polymers like polyacrylamide.

- Robust Design: Operates in harsh treatment environments, withstanding high temperatures and shear conditions.

- Integrated Temperature Monitoring: High-accuracy ensures precise temperature-compensated viscosity readings.

- Seamless Automation: Integrates with PLC and DCS systems for automated dosing adjustments.

- Low Maintenance: Compact, consumable-free design ensures long-term reliability.

Unlike offline methods like Pour or Gravity Drainage Tests, Lonnmeter’s viscometer delivers continuous, accurate data, eliminating sampling delays and errors, and ensuring precise flocculant dosing for optimal floc formation.

Benefits of Viscosity Automation in Polymer Blending

Viscosity automation in polyelectrolyte dosing delivers transformative advantages for water treatment plants, enhancing efficiency and sustainability:

- Optimized Polymer Dosing: Real-time viscosity control ensures precise polyelectrolyte concentrations, improving floc quality and settling efficiency.

- Reduced Chemical Consumption: Accurate dosing minimizes polymer waste, lowering costs and environmental impact.

- Lower Energy Usage: Optimized mixing reduces energy demands, enhancing operational efficiency.

- Enhanced Regulatory Compliance: Consistent dosing prevents discharge violations, avoiding penalties.

- Proactive System Protection: Immediate anomaly detection prevents blockages, pipe bursts, or treatment failures.

- Integration with Advanced Systems: Compatibility with AI-driven analytics and digital twins enables predictive dosing and process optimization.

- Improved Solids Capture: Maintains cake concentration below 200 ppm, supporting nutrient recovery and sludge management.

These benefits mirror the precision seen in processes like the continuous fermentation of penicillin, ensuring reliability and cost-effectiveness.

The coagulation and flocculation process is critical in achieving high-quality water and wastewater output. Lonnmeter’s online polyelectrolyte viscometer revolutionizes this process by providing real-time viscosity monitoring, eliminating the inefficiencies of offline testing, and ensuring optimal flocculant dosing.

Take control of your coagulation process in wastewater treatment—contact Lonnmeter today to request a tailored quote and elevate your facility’s efficiency and compliance!

Post time: Aug-15-2025