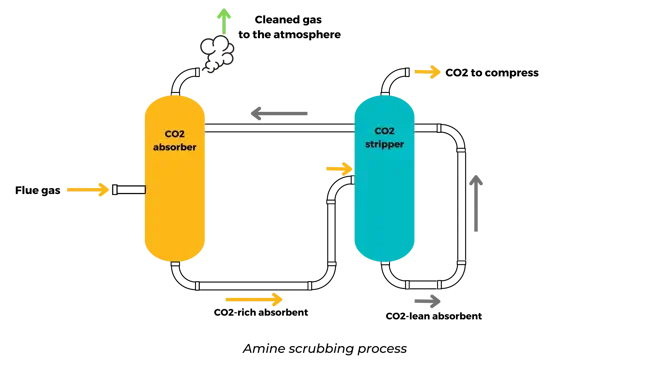

Amine scrubbing, also known as amine sweetening, is an essential chemical process to capture acid gases like CO2 or H2S, especially in industries like natural gas processing plants, petrochemical plants, biogas upgrading plants, and hydrogen production plants. The amine scrubbing process is critical for removing acidic gases like CO2 or H2S from gas streams to prevent corrosion in further transport according to pipeline requirements.

Why MDEA Concentration Matters in Amine Scrubbing

MethylDiEthanolAmine (MDEA) is a widely used amine in amine scrubbing systems due to its efficiency in selectively removing CO2 or H2S. Maintaining the correct MDEA solution concentration is critical for several reasons:

- Process Efficiency: Optimal MDEA concentration ensures maximum absorption of acidic gases, reducing energy consumption in the amine gas sweetening plant.

- Cost Reduction: Precise control minimizes amine overuse, lowering operational costs and reducing waste.

- Regulatory Compliance: Accurate monitoring ensures compliance with environmental standards by effectively removing CO2 or H2S, aligning with sustainability goals.

Challenges in Controlling MDEA Concentration

Inline MDEA concentration monitoring in amine scrubbing processes encounters the tricky challenges like inconsistent measurements, which may cause pipeline and equipment corrosion in case that acid gas CO2 or H2S fail to be captured thoroughly. Moreover, inaccurate amine concentrations can increase energy use in regeneration cycles, impacting operational efficiency.

Lonnmeter Solutions for Inline MDEA Concentration Monitoring

Engineers of lonnmeter have provided effective solutions to help such target plants in precise MDEA concentration monitoring by integration natural gas sweetening units with ultrasonic concentration meter. It calculates sonic velocity according to transmission time in measured media, then infer concentration of amine solutions in streams.

The mechanical performance will not degrade with time for no moving parts. The sensor calculates sonic velocity by fixed distance between ultrasonic transmitter and receiver. The measuring method is unconstrained by conductivity, color and transparency of media while maintaining the optimal reliability and accuracy up to 0.05%.

The amine concentration analyzers are designed to address the challenges of inline MDEA concentration control, enabling real-time data monitoring and minimizing maintenance frequency and equipment shutdown time.

Benefits of Lonnmeter Process Sensors

Unexpected Accuracy

The amine concentration meter unmatched accuracy 0.05%~0.1%. This exceptional accuracy ensures precise monitoring of MDEA concentration in processes like natural gas sweetening and CO2 amine scrubbing, enabling optimal absorption of acidic gases like CO2 or H2S while minimizing energy consumption and amine waste.

Real-Time Monitoring & Adjustments

Its seamless integration with PLC and DCS systems via standard protocols like 4-20mA and RS 485 enables real-time data transmission, allowing immediate process adjustments. This minimizes energy waste from over-regeneration, saving up to 15-20% in energy costs in natural gas sweetening by amine solution.

Cost Reduction

By optimizing MDEA solution concentration control, these sensors minimize energy consumption, reduce amine waste, lower maintenance costs, and prevent costly downtime, making them a game-changer for amine gas sweetening plants preparing sour natural gas for safe pipeline transport while avoiding corrosion-related expenses.

Accurate monitoring prevents amine degradation from improper concentration, extending the usable life of MDEA solutions. This reduces replacement frequency, lowering chemical procurement costs by 5-10% annually.

FAQs

What Is Amine Scrubbing and Why Is MDEA Used?

Amine scrubbing is a process used in amine gas sweetening plants to remove acidic gases like CO2 or H2S from gas streams. MDEA is favored due to its high selectivity for CO2 and H2S, lower energy requirements for regeneration, and reduced corrosiveness.

What Are the Benefits of Real-Time MDEA Concentration Monitoring?

Real-time monitoring with MDEA concentration meters provides immediate data on amine levels, enabling rapid adjustments to maintain operational efficiency. Benefits include reduced energy consumption, lower amine usage, extended equipment life, and compliance with sustainability goals in natural gas sweetening by amine solution.

Controlling inline MDEA concentration is critical for optimizing amine sweetening processes in natural gas processing plants, petrochemical plants, biogas upgrading plants, and hydrogen production plants. By addressing challenges like inconsistent measurements, high energy consumption, MDEA concentration meters empower businesses to achieve operational efficiency, cost reduction, and sustainability.

With real-time data, robust sensor designs, and strategic implementation, these instruments transform the amine gas sweetening process, ensuring compliance and maximizing performance. Ready to enhance your amine scrubbing system? Contact Lonnmeter at lonnsales@xalonn.com or visit www.lonnmeter.com to explore our cutting-edge solutions.

Post time: Jun-24-2025