Industrial densitometers for slurry measurement ensure uniform acetal polyoxymethylene properties, supporting consistent mechanical strength and thermal stability in acetal plastic applications. High-accuracy slurry density meters also cut material costs by optimizing dosing, according to industry reports that show savings of 7–9% per batch. Online process density monitoring minimizes manual handling, lowering operational downtime by up to 20%.

Advanced industrial process control density meters provide key feedback for acetal slurry blenders, automating adjustments during the mixing process. This results in tighter process tolerances and fewer off-spec batches, maximizing throughput and resource efficiency.

Acetal / Polyoxymethylene (POM)

*

Introduction

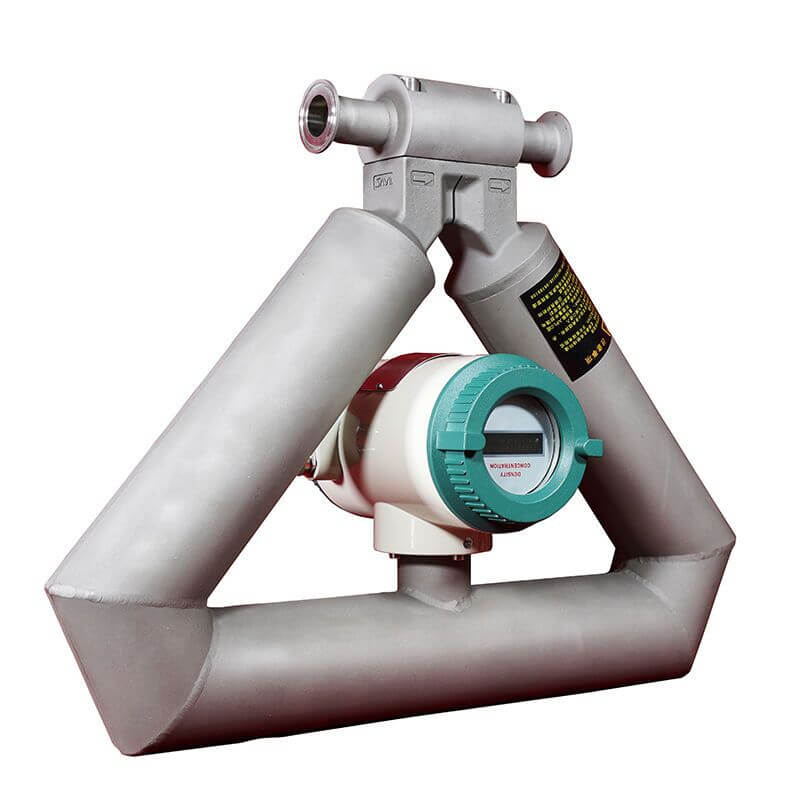

Inline density and concentration measurement maintains strict control of acetal slurry blending. High-accuracy slurry density meters deliver real-time data for each acetal polyoxymethylene batch. Industrial densitometer for slurry measurement ensures consistent particle dispersion and solution homogeneity. Process density measurement techniques prevent agglomeration and enable precise adjustment in acetal slurry blender use. Using industrial process control density meters enables automated online process density monitoring and nearly eliminates manual intervention. Tuning fork density meter applications support direct correction of feed or dilution rates, cutting product variation. Inline instruments from Lonnmeter measure both density and concentration, supporting all acetal plastic applications, meeting yield and quality requirements. Slurry density measurement methods reduce raw material losses, waste, and downtime stemming from misblends.

Overview of Acetal Slurry Processing

Acetal polyoxymethylene (POM) is processed into liquid slurries for automotive, electronics, and chemical manufacturing. POM’s high stiffness (tensile modulus ~ 2.8 GPa), low friction coefficient (~0.2), and density (1.41–1.43 g/cm³) allow precise, dimensionally stable blends under agitation. Slurry blending maintains uniform particle distribution to support high-quality acetal plastic applications and minimize wear during downstream processing.

Industrial density meters, such as inline density meters and industrial densitometers for slurry measurement, deliver real-time, high-accuracy readings. Online process density monitoring ensures rapid response to density fluctuations, supporting process control by acetal slurry blenders and reducing agglomeration risk. Continuous monitoring by high-accuracy slurry density meters prevents deviations that cause non-uniform blends, defects, and excessive raw material use. Tuning fork density meter applications enhance control in continuous and batch processes, making these industrial process control density meters essential for optimizing acetal slurry density measurement throughout production.

POM (Polyacetal) production process

*

Challenges in Inline Density/Concentration Measurement

Agglomeration in acetal slurry results in sensor fouling and random distribution, skewing readings from industrial density meters by up to 8%. Fluctuations in viscosity and variable particle sizes alter response time and accuracy in tuning fork density meter applications, complicating calibration and real-time control. Rapid temperature changes—±3°C shifts—impact slurry density by up to 1.2%, threatening stability in online process density monitoring. Manual sampling introduces data delays up to 7 minutes and operator bias, undermining high-accuracy slurry density measurement. Sensor material incompatibility with acetal polyoxymethylene properties can trigger surface swelling, causing drift in industrial densitometer for slurry measurement. Industrial process control density meters must provide robust performance despite acetal slurry blender use irregularities, preventing misreads and optimizing acetal plastic applications. Strict adherence to appropriate slurry density measurement methods is essential to assure continuous, reliable performance.

Benefits of Integrating Inline Density/Concentration Meters

Inline density meters enable immediate correction of acetal slurry composition by providing real-time, continuous process density measurement. Tuning fork density meter applications deliver instant feedback for slurry density adjustment, minimizing excess raw material use and preventing off-spec batches. High-accuracy slurry density meters consistently maintain acetal polyoxymethylene properties during blending, ensuring uniform particle distribution and enhanced product consistency. Industrial densitometer for slurry measurement automates control, reducing manual operator intervention and sampling errors, resulting in a more streamlined production line. Lonnmeter’s inline density meter solutions are scalable and adapt to varying acetal plastic applications, supporting diverse manufacturing requirements. Modern online process density monitoring increases throughput, eliminates process delays, and lowers operational costs associated with manual quality checks. Industrial process control density meters designed for abrasive slurries require less frequent maintenance compared to conventional instruments, with robust materials engineered to withstand aggressive slurry environments and frequent temperature changes.

Integrate Lonnmeter instrumentation for precise control of acetal slurry blender use, online process density monitoring, and robust industrial process control density meters across diverse acetal plastic applications. Request for quote right now.

Post time: Jan-22-2026