Inline Viscosity Measurement

Inline viscosity measurement is a technique for continuously monitoring the viscosity of a fluid directly within a process line. Unlike traditional laboratory methods that require manual sampling and off-line analysis, inline viscometers provide real-time data, allowing for immediate process adjustments. This ensures consistent product quality, optimizes efficiency, and reduces waste in manufacturing and processing applications.

Solutions for Online Viscometer Measurement

Gelatin Capsule Production

Viscosity and density of gelatin solution determine capsule shell thickness and weight, as well as flow of gelatin.

PVT Analysis in Oil Reservoirs

Pressure-Volume-Temperature (PVT) analysis is essential for understanding how reservoir fluids behave under varying conditions in the oil industry.

LNG Shipping and LNG Transport

Continuous monitoring of density is vital to prevent operational issues such as tank instability and inefficient pumping in LNG shipping. Fluctuations in density can lead to...

Chemical Mechanical Polishing

The chemical-mechanical polishing (CMP) is often involved with producing smooth surfaces by chemical reaction, especially works in the industry of semiconductor manufacturing.

Glaze Slurry Viscosity Control

Crystallization is a critical step in pharmaceutical manufacturing, used for the purification and formulation of APIs.

Ink Viscosity Control

Ink viscosity has a direct influence on final print results and quality in press rooms while it’s an often-overlooked measurement.

Viscosity Control of Battery Slurry

Battery electrode slurry preparation is essential in battery manufacturing for poor battery slurry mixing can lead to inefficient electron conduction. Then it would result in non-uniform battery reactions.

Fuel Atomization Processes

The atomizing process involves breaking down liquid fuels—such as heavy oil, diesel, or kerosene—into fine droplets using atomizing air pressure or mechanical nozzles.

Drilling Mud

Well drilling process lasts for months in the oil and gas industry, which requires precise real-time monitoring of drilling mud to lubricate the drill bit, remove cuttings, and stabilizes the wellbore.

Polymer Melt Viscosity Measurement

Polymer melt viscosity measurement determines extrusion and molding process. Real-time viscosity monitoring is more important than temperature and pressure monitoring.

Viscosity Monitoring of Coolant

Precise caprolactam concentration measurement is essential for efficient caprolactam production processes.

Viscosity of Non-Newtonian Fluids

Mixing is an essential link in numerous manufacturing processes. Under mixing and over mixing are two circumstances often occurred in agitation, also factors leading to non-full capacity production.

Coating and Finishing Processes

Coatings serve a multitude of purposes, from providing corrosion and abrasion resistance to enhancing UV protection, thermal insulation, and aesthetic appeal.

Cable Coating Process

To ensure consistent high-quality, uniform coating, the change in viscosity through-out the process stream is monitored in real time

Glue Viscosity Measurement

Glue viscosity refers to a glue’s resistance to flow, a critical property that determines how it behaves during application in industrial processes. Two viscosity unit centipoise (cP)...

Pharmaceutical Fermentation Processes

Fermentation monitoring and process control mean creating perfect growing and fermentation environment for microbial, Then keep a stable efficiency, yield and consistent product quality.

Lubricant Viscosity Measurement

Lubricants are utilized in extensive industries like automobile industry, chemical, construction, textile, infrastructure, agriculture...

Polyelectrolyte Preparation and Dosing

The coagulation process in water treatment aims at removing suspended solids, colloids, and organic matter from water and wastewater. This process involves two key stages...

Asphalt Mixing Process

Asphalt viscosity and temperature matter in production of Hot Mix Asphalt (HMA). The asphalt-cement viscosity specifies resistance to compaction of paving mixture...

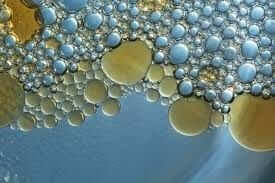

Emulsions Formulation Processing

Emulsions permeate industries such as food, cosmetics, oil and gas, agriculture, chemicals, pharmaceuticals, and beyond. It’s prone to separate without rigorous management and processing.

Pesticide Production Process

Pesticide concentration and pesticide viscosity are two primary parameters that directly determine product quality. Their stability and rationality run through the entire pesticide production process ...

Tablet Coating Process

The tablet coating process transforms raw tablets into sophisticated products that balance efficacy, stability, and patient appeal. Film coating, a critical step.

Pharmaceutical Continuous Manufacturing

Inline viscosity control transforms pharmaceutical manufacturing by enabling real-time monitoring and adjustments.

Hotmelt Adhesive Dispensing Systems

Continuous viscosity control emerges as a pivotal strategy for elevating hotmelt adhesive production line efficiency. Observe how ...

Viscosity Measurement of Polymer Solution

Every variable can tip the scales between excellence and mediocrity in industrial manufacturing. Precise viscosity control in process is

Fuel Oil Viscosity Control System

The performance of any fuel, particularly heavy fuel oil viscosity control, is never a matter of chance.

Polyurethane Production Process

The production of polyurethane (PU) coatings and adhesives is a complex, multi-stage process governed by sensitive chemical reactions. While the demand for these materials continues to grow across industries

Cosmetics Viscosity

The modern cosmetic manufacturing industry is characterized by complex formulations, often comprising non-Newtonian fluids. The inherent rheological behaviors of these materials ...

Epoxy Resin Manufacturing Process

Epoxy resins are essential in an extensive array of industrial scenarios, ranging from composite material manufacturing to the development of specialized adhesives.

Paraffin Wax Viscosity

The production of paraffin wax involves managing the physical state of a complex mixture of saturated hydrocarbon fractions. A key challenge is controlling the transition from a molten state

Bitumen Viscosity Measurement

If the viscosity of bitumen exhibits fluctuations during the blending or coating stages, the resulting polymer-bitumen matrix will inevitably be non-homogeneous, leading to ...

Shale Oil Viscosity

The successful application of continuous viscosity measurement systems in the field of shale oil extraction and oil sands extraction demands a clear recognition of ...

PET Viscosity Measurement

Polymeter viscosity measurement can make or break the whole production process of synthesis of PET. For those entrenched in the PET industry, the shift from...

Yarn Sizing

The yarn sizing process involves applying a protective coating to warp yarns to enhance their weaveability, a practice essential for preventing damage during high-speed weaving. This procedure, often referred to as yarn sizing, fortifies the yarns ...

Chocolate Production Process

Effective chocolate viscosity measurement affects the flow, coating uniformity, and texture of chocolate products, whether in bars, confections, or enrobed goods. Inconsistent chocolate coating viscosity can result in ...

Hair Conditioner Manufacturing

Online high-shear viscometers deliver precise, real-time viscosity measurements directly within production lines. For non-Newtonian fluids like shampoo and conditioner—which exhibit shear-thinning behavior where viscosity drops under flow...

Glycol Viscosity Determination

The effective management of antifreeze solutions in petrochemical pipelines demands proactive, data-driven strategies that integrate seamlessly into existing infrastructures. The emphasis on real-time glycol water viscosity...

Glue Viscosity Measurement

Precise viscosity measurement weights in underfill, die attach, and encapsulation of semiconductor packaging for optimal precision and reliability. Underfill constitutes an epoxy-based compound...

Rubber Processing

The successful production of Styrene Butadiene Rubber (SBR) depends on the precise control and monitoring of its rheological properties. Viscosity, which quantifies a material's resistance to flow, stands as the single most critical physicochemical...

Steam Turbine Power Plant

Steam turbines in power plants and factories apply lubricating oil for long-term smooth operation even in high pressure and temperature conditions. Continuous viscosity measurement of lube oil determines life span ...

Demulsification of Crude Oil

The conditioning of raw crude oil—a process encapsulated by crude oil dehydration and desalting process (D/D/D)—represents one of the most critical and expensive steps in hydrocarbon production and refining.