Fluid Density Measurement for Flue Gas Desulfurization Process Optimization

Combustion of fossil fuels yields a significant environmental byproduct: sulfur dioxide (SO₂) gas, with more than 95% of the sulfur in the fuel converting into SO₂ under typical operating conditions. This acidic gas is a major air pollutant, contributing to acid rain and posing substantial risks to human health, cultural heritage, and ecological systems. The mitigation of harmful emissions has led to the adoption of flue gas desulfurization process technologies.

Differentiating the Desulfurization & Denitration Processes

In the discourse of modern emissions control, a clear distinction must be drawn between flue gas desulfurization process and denitration process. While both are critical for environmental compliance, they target fundamentally different pollutants and operate on distinct principles. The denitration process is specifically designed to remove nitrogen oxides (NOx). This is often achieved through technologies like Selective Catalytic Reduction (SCR) or Selective Non-Catalytic Reduction (SNCR), which facilitate the conversion of NOx to inert molecular nitrogen.

The desulfurization process, as executed in WFGD systems, chemically absorbs acidic SO₂ gas using an alkaline medium. Although some advanced systems, such as the SNOX process, are designed for the simultaneous removal of both sulfur and nitrogen oxides, their underlying mechanisms remain separate chemical pathways. Understanding this difference is crucial for effective system design and operational strategy, as the measurement and control parameters for each process are unique.

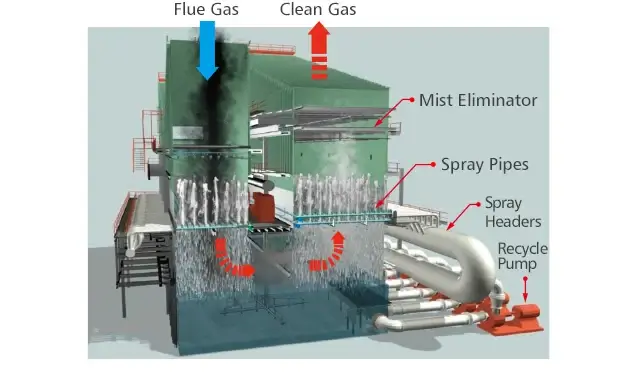

The Centrality of the Slurry

The heart of the WFGD system is the absorber, where SO₂-laden flue gas flows upward through a dense mist or spray of alkaline slurry, typically a mixture of finely ground limestone and water. The efficiency and stability of this chemical interaction are entirely dependent on the physical and chemical properties of the slurry itself. Its composition is dynamic and complex, encompassing solid particles of limestone and gypsum, dissolved chemical species like calcium and sulfate ions, and impurities such as chlorides. While traditional control strategies have relied on parameters like pH to infer the slurry's condition, a more comprehensive approach is required to achieve true operational excellence. This is where online fluid density measurement emerges as an indispensable tool. It provides a direct, quantitative measure of the total solids concentration—a variable that influences reaction kinetics, equipment reliability, and system economics in ways that other metrics cannot. By moving beyond simple inferential control, engineers can unlock the full potential of their desulfurization process by making the unseen variable of slurry density a primary driver of process optimization.

Have questions about optimizing production processes?

The Chemical and Physical Nexus of WFGD Slurry Dynamics

The Limestone-Gypsum Reaction Cascade

The WFGD process using limestone-gypsum is a sophisticated application of chemical engineering principles designed to neutralize acidic flue gases. The journey begins in a slurry preparation tank where finely ground limestone (CaCO₃) is mixed with water. This slurry is then pumped to the absorber tower, where it is sprayed downward. In the absorber, SO₂ gas is absorbed by the slurry, leading to a series of chemical reactions. The initial reaction forms calcium sulfite (CaSO₃), which is then oxidized by air introduced into the reaction tank. This forced oxidation converts the calcium sulfite into stable calcium sulfate dihydrate, or gypsum (CaSO₄·2H₂O), a marketable byproduct used in the construction industry. The overall reaction can be simplified as:

SO2(g)+CaCO3(s)+21O2(g)+2H2O(l)→CaSO4⋅2H2O(s)+CO2(g)

The conversion of a waste product into a resource is a powerful economic and environmental incentive, directly contributing to the circular economy.

Slurry as a Multiphase, Dynamic System

The slurry is far more than just a mixture of limestone and water. It is a complex, multiphase environment where the density is a function of suspended solids—including unreacted limestone, newly formed gypsum crystals, and residual fly ash—along with dissolved salts and entrained gas. The concentration of these components fluctuates continuously, impacted by factors such as the quality of the incoming coal, the efficiency of upstream particulate removers like electrostatic precipitators, and the flow of makeup water. A critical impurity to manage is the chloride content, which can originate from the coal, makeup water, or cooling tower blowdown. Chlorides form soluble calcium chloride (CaCl₂) in the slurry, which can suppress limestone dissolution and reduce overall desulfurization efficiency. High chloride concentrations also pose a severe risk of accelerating corrosion and stress cracking in the system's metal components, necessitating a continuous purge flow to maintain a safe and stable environment. The ability to accurately and consistently measure the overall density of this dynamic mixture is therefore paramount for system integrity.

The Crucial Interplay of Density, pH, and Particle Size

Within the desulfurization process, the kinetics of the chemical reactions are highly sensitive to several interconnected parameters. The fineness of the limestone particles, for example, is a primary determinant of its dissolution rate. A finely ground limestone dissolves much faster than a coarse one, leading to an improved SO₂ absorption rate. Similarly, the slurry's pH is a central control parameter, typically maintained within a narrow range of 5.7 to 6.8. A pH that falls too low (below 5) will render the scrubber inefficient, while a pH that rises too high (above 7.5) can lead to the formation of abrasive scales of CaCO₃ and CaSO₄ that can clog nozzles and other equipment.

The conventional control strategy relies on adding more limestone to maintain a constant pH, but this approach is a simplification that overlooks the slurry's total solid content. While pH provides information on the slurry's acidity, it does not directly measure the concentration of reactants and byproducts. The relationship between pH and density presents a compelling case for a more advanced control scheme. A high pH, which is beneficial for SO₂ removal, is paradoxically detrimental to the rate of limestone dissolution. This creates a fundamental operational tension. By introducing real-time density measurement into the control loop, engineers gain a direct measure of the mass of suspended solids in the slurry, including the critical limestone and gypsum particles. This data allows for a more nuanced understanding of the system's health, as a rising density that is not reflected in a change in pH could indicate a buildup of unreacted solids or a dewatering issue. This deeper understanding enables a shift from simply reacting to a low pH reading to proactively managing the system's solids balance, thereby ensuring consistent performance, reducing wear, and optimizing reagent use.

Learn About More Density Meters

Value Drivers of Precise Density Monitoring

Driving Process Optimization and Efficiency

Precise, real-time density measurement is essential in WFGD process optimization. This stoichiometric accuracy prevents wasteful over-dosing, which directly translates into reduced material consumption and lower operational expenditure. The effectiveness of the desulfurization process is measured by its ability to maintain low SO₂ emission concentrations, which for many new facilities, must not exceed 400 mg/m³. A density control loop ensures the system is operating at its peak efficiency to consistently meet these critical emission standards.

Enhancing Equipment Reliability and Longevity

The aggressive nature of the WFGD environment presents a continuous threat to equipment reliability. The abrasive and caustic slurry causes significant mechanical wear and chemical corrosion on pumps, valves, and other components. By maintaining the slurry density within a precisely controlled range (e.g., 1080–1150 kg/m³), operators can prevent the formation of scales. This is crucial, as the supersaturation of calcium sulfate (CaSO₄) is the leading cause of scaling and deposition, which can clog nozzles, spray headers, and mist eliminators. A direct consequence of this scaling is frequent, unplanned plant downtime for cleaning and descaling, which is both costly and disruptive.

The ability to monitor and control slurry density also serves as a critical defense against abrasion and corrosion. By using density data to regulate slurry flow velocities, operators can minimize the mechanical wear on pumps and valves. Furthermore, controlling the density helps manage the concentration of detrimental substances like chlorides. High chloride levels can dramatically accelerate the corrosion of metal components, necessitating a costly purge flow to remove them. By using a density meter to monitor these levels, the plant can optimize the purge process, thereby reducing water waste and preventing premature equipment failure. This is not just a matter of operational stability; it is a strategic investment in the longevity of the plant's capital assets, directly reducing the total cost of ownership.

The Economic and Strategic Value

The economic value of a precise online density measurement system extends far beyond its immediate operational impact. The initial capital expenditure for a high-performance sensor is a strategic investment that yields tangible returns. By optimizing reagent dosing, a plant can significantly reduce its consumption of limestone, which is a major operational cost. Lowering this cost and simultaneously ensuring compliance with emission standards is a dual-objective optimization problem that sophisticated control systems are designed to solve.

Furthermore, precise density control enhances the value of the WFGD byproduct. The purity of the gypsum, which is directly affected by slurry concentration, determines its marketability. By managing the slurry to produce a high-purity, easily dewatered gypsum, a plant can generate additional revenue, thereby offsetting the costs of the desulfurization process and contributing to a more sustainable operation. The ability of real-time density data to prevent unplanned shutdowns from scaling and corrosion also protects the plant's revenue stream by ensuring consistent, uninterrupted production. The initial investment in a quality density sensor is not merely an expense; it is a fundamental component of a cost-effective, reliable, and environmentally responsible operation.

Comparision of Online Density Measurement Technologies

Foundational Principles and Challenges

Selecting the appropriate online density measurement technology for a WFGD system is a critical engineering decision that balances cost, accuracy, and operational robustness. The highly abrasive, corrosive, and dynamic nature of the slurry, coupled with the potential for gas entrainment and bubble formation, presents significant challenges for many sensors. The presence of bubbles is particularly problematic, as they can directly interfere with the sensor's measurement principle, leading to inaccurate readings. Therefore, the ideal technology must be not only precise but also rugged and designed to withstand the hostile conditions of the flue gas desulfurization process.

Differential Pressure (DP) Measurement

The differential pressure method relies on the hydrostatic principle to infer fluid density. It measures the pressure difference between two points at a known vertical distance within the fluid. While this is a mature and widely understood technology, its application in WFGD slurries is limited. The impulse lines that connect the sensor to the process fluid are highly susceptible to clogging and fouling. Furthermore, the principle typically assumes a constant fluid density to calculate level from pressure, an assumption that is invalid in a dynamic, multiphase slurry. While some advanced configurations use two transmitters to mitigate these issues, the risk of blockage and maintenance requirements remain significant drawbacks.

Gamma-Ray (Radiometric) Measurement

Gamma-ray density gauges operate on a non-contact principle, where a radioactive source (e.g., Cesium-137) emits gamma photons that are attenuated as they pass through the process fluid. The detector measures the amount of radiation that passes through the pipe, and the density is inversely proportional to this reading. The key advantage of this technology is its complete immunity to the abrasive, corrosive, and caustic conditions of the slurry, as the sensor is mounted externally to the pipe. It also requires no bypass piping or direct contact with the process fluid. However, gamma-ray gauges come with a high cost of ownership due to stringent safety regulations, licensing requirements, and the need for specialized personnel for handling and disposal. These factors have led many plant operators to actively seek non-nuclear alternatives.

Vibrating Fork/Resonator Measurement

This technology utilizes a tuning fork or resonator that is excited to vibrate at its natural resonance frequency. When immersed in a liquid or slurry, this frequency changes, with a higher density causing a lower vibration frequency. The sensor's robust, direct insertion design makes it suitable for continuous, real-time measurement in pipelines or tanks. It has no moving parts, which simplifies maintenance. However, this technology is not without its challenges. It is sensitive to entrained gas bubbles, which can cause significant measurement errors. It is also vulnerable to coating and fouling, as deposits on the tines can alter the resonance frequency and compromise accuracy. Proper installation with vertical tines is crucial to mitigate these issues.

Coriolis Measurement

The Coriolis mass flowmeter is a multi-variable instrument that can simultaneously measure mass flow, density, and temperature with high accuracy. The principle is based on the Coriolis force generated as the fluid flows through a vibrating tube. The density of the fluid is determined by monitoring the resonant frequency of the tube's vibration, which decreases as density increases. This technology has emerged as a preferred non-nuclear alternative for challenging applications like WFGD. A notable case study highlights the successful use of a Coriolis meter with a single straight-tube design and a titanium sensor tube. This specific design effectively addresses the abrasion and clogging issues common with slurries, while the high accuracy and multi-variable output provide superior process control. The strategic move to non-nuclear technologies like Coriolis meters represents a fundamental shift away from the historical trade-off between reliability and cost, offering a single solution that is robust, accurate, and safe.

The selection of a density meter for a WFGD application requires a comprehensive evaluation of each technology's strengths and weaknesses in the context of the slurry's specific characteristics.

Online Density Measurement Technologies Comparison for WFGD Slurries

|

Technology |

Working Principle |

Key Advantages |

Key Disadvantages & Challenges |

WFGD Applicability & Notes |

|

Differential Pressure (DP) |

Hydrostatic pressure difference between two points |

Mature, low initial cost, simple |

Prone to blockages and zero drift, requires constant density assumption for level |

Generally not suitable for WFGD slurries due to clogging risk. Requires significant maintenance . |

|

Gamma-Ray (Radiometric) |

Non-contact, measures radiation attenuation |

Immune to abrasion, corrosion, and caustic pH; no need for bypass piping |

High cost of ownership, significant regulatory/safety burden |

Historically used due to immunity to harsh conditions. The high operational cost is driving a shift to alternatives. |

|

Vibrating Fork/Resonator |

Vibration frequency inversely proportional to density |

Real-time, direct insertion, low maintenance |

Susceptible to errors from entrained gas/bubbles; vulnerable to contamination and coating |

Used for lime slurry and gypsum slurry density measurement. Proper installation is critical to prevent clogging and erosion. |

|

Coriolis |

Measures Coriolis force on a vibrating tube |

Multivariable (mass, density, temp), high accuracy |

Higher initial cost than other in-line meters; requires specific design for abrasive media |

Highly effective when using a straight-tube design and abrasion-resistant materials like titanium. A viable non-nuclear alternative. |

|

Emerging Technologies |

Accelerometer, Ultrasonic Spectroscopy |

Non-nuclear, high resistance to abrasion, low maintenance |

Less widespread industrial adoption; specific application limitations |

Present a promising, cost-effective, and safe alternative for the most challenging slurry applications . |

Engineering Solutions for a Hostile Environment

Material Selection as the First Line of Defense

The severe operating conditions within a WFGD system demand a proactive engineering response. The slurry is not only abrasive but can also be highly corrosive, particularly with elevated chloride levels. Consequently, the selection of materials for pumps, valves, and piping is the first and most critical line of defense. For handling high-volume slurry recirculation, hard-metal or rubber-lined pumps are the best choice, as their robust construction can withstand the continuous wear from suspended solids. Valves, particularly large knife-gate valves, must be specified with upgraded materials, such as replaceable urethane liners and robust scraper designs, to prevent media buildup and ensure longevity. For smaller lines, diaphragm valves with thick rubber liners offer a reliable and economic solution. Beyond these components, the absorber vessels themselves often utilize specialized alloys or corrosion-resistant linings to handle the aggressive, chloride-rich environment.

Sensor Protection and Optimal Installation Design

The effectiveness of any online density sensor is contingent upon its ability to survive and perform in the hostile WFGD environment. Consequently, sensor design and installation are paramount. Modern sensors employ sophisticated features to combat scaling and abrasion. For instance, the single straight-tube design of some Coriolis meters prevents clogging by being self-draining and avoiding pressure loss. The sensor tubes are often constructed from highly durable materials like titanium to resist wear. Some newer technologies, such as certain vibrating sensors, incorporate "self-cleaning harmonics" that use vibrations to prevent slurry deposition on the probe, ensuring continuous and accurate readings without the need for manual cleaning.

Proper installation is equally important. For larger diameter pipes (e.g., 3-inch or greater), a T-Piece installation is recommended to ensure a representative sample. The sensor must be installed at an angle that allows it to self-drain. Furthermore, maintaining an optimal flow velocity—high enough to keep solids in suspension (e.g., 3 m/s) but not so high as to cause excessive erosion (e.g., above 5 m/s)—is critical for long-term reliability and accurate measurement.

Mitigating Measurement Interference

Beyond mechanical wear, density measurements can be compromised by physical phenomena like gas entrainment. Bubbles from oxidation air, which is continuously introduced into the system, can become entrained in the slurry and lead to inaccurate readings. This is a particular concern for vibrating sensors, which rely on the fluid's mass to determine density. A simple but effective engineering solution is to ensure the sensor's tines are oriented vertically, allowing entrained gas to rise and escape, thereby minimizing its impact on the measurement. While a direct consequence of the physics, this simple adjustment highlights the importance of correct installation in ensuring the reliability of even the most robust instruments.

Advanced Integration and Process Control

Architecting the Control Loop

The true value of online fluid density measurement is realized when its data is integrated into the plant's control architecture. Density meters produce standardized output signals, such as 4-20 mA analog output or RS485 MODBUS communication, which can be seamlessly integrated into a plant's Distributed Control System (DCS) or Programmable Logic Controller (PLC). In the most basic control loop, the density signal is used to automate the management of the slurry's solids concentration. The DCS analyzes the real-time density data and adjusts the speed of a variable-frequency-drive pump or the position of a control valve to maintain the desired solids ratio. This removes the need for manual intervention and ensures a stable, consistent process.

The Multivariable Approach

While a standalone density control loop is beneficial, its power is multiplied when it becomes part of a comprehensive, multivariable control system. In such an integrated system, density data is correlated with and used to complement other critical parameters to provide a more holistic view of the desulfurization process. For instance, density measurements can be used in tandem with pH sensors. A sudden drop in pH might indicate a need for more limestone, but a concurrent drop in density would suggest a broader problem with the limestone feed or a dewatering issue that requires a different corrective action. Conversely, a rising density without a corresponding drop in pH could signal a problem with the absorber's oxidation or gypsum crystal growth, long before the SO₂ removal efficiency is impacted.

Furthermore, integrating density with flow measurement allows for the calculation of mass flow, which provides a more accurate picture of material balance and feed rate than volumetric flow alone. The highest level of integration connects density and flow data to upstream and downstream parameters, such as the inlet SO₂ concentration and Oxidation-Reduction Potential (ORP), allowing for a truly optimized control strategy that maintains high SO₂ removal efficiency while minimizing reagent use and energy consumption.

Data-Driven Optimization and Predictive Maintenance

The future of WFGD process control is moving beyond traditional reactive loops. The continuous stream of high-quality data from online density meters and other sensors provides the foundation for data-driven frameworks that leverage machine learning and artificial intelligence. These advanced models can ingest a vast amount of historical and real-time data to identify optimal operating parameters under a wide range of conditions, such as fluctuating coal supplies or varying unit loads.

This advanced approach represents a fundamental shift in operational philosophy. Instead of simply reacting to alarms that indicate a parameter is out of its set range, these systems can predict the onset of a problem and proactively adjust parameters to prevent it. The primary objective of these models is to optimize for multiple, sometimes contradictory, goals simultaneously, such as reducing the desulfurization process cost and minimizing SO₂ emissions. By continuously analyzing the plant's "fingerprint" of operational data, including density, these systems can consistently achieve the highest level of sustainability and economic efficiency.

The data and analysis presented in this report demonstrate that precise online fluid density measurement is not an optional accessory but an indispensable tool for achieving operational excellence in Wet Flue Gas Desulfurization systems.